Solid synchronous enzymolysis fermentation method for lignocellulose airborne ethanol particles packed bed

A lignocellulose, particle packed bed technology, applied in fermentation, biofuel and other directions, can solve the problems of low ethanol yield and strong product inhibition, achieve high fermentation substrate concentration and product yield, operation and extraction Simple and controllable process, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

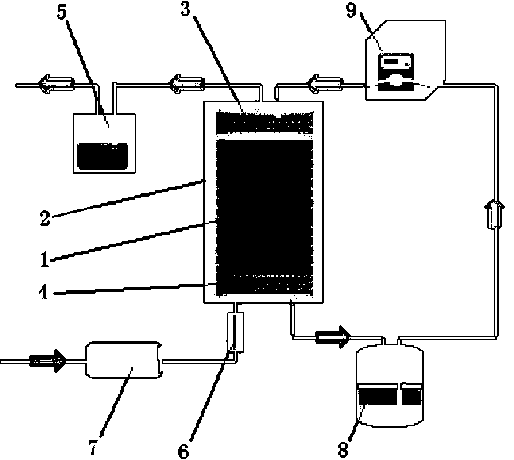

[0022] A solid-state synchronous enzymatic hydrolysis fermentation method for lignocellulose airborne ethanol particles packed bed, the method comprises the following steps:

[0023] A. Making embedding granules: Cellulase, cellobiase, xylosidase, and straw with a particle size of 40-80 meshes are made of polyvinyl alcohol and sodium alginate to form embedding granules. The method of making embedding granules is as follows: Weigh a certain amount of sodium alginate and polyvinyl alcohol into a beaker with an appropriate amount of water, heat and dissolve, then cool it to room temperature, add cellulase, cellobiase and xylase, mix well, and then mold It is made into embedding particles, and the particle size of the embedding particles is 2-6mm; then the embedding particles are put into 2 Cross-link in a saturated boric acid solution at 4-5°C for 12-24 hours; then wash off the boric acid and calcium chloride (CaCl) on the surface of the embedded particles 2 ) solution, as a spa...

Embodiment 2

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] A solid-state synchronous enzymatic hydrolysis fermentation method for lignocellulose airborne ethanol particles packed bed, the method comprises the following steps:

[0031] A. Making embedding granules: Cellulase, cellobiase, xylosidase, and straw with a particle size of 40-80 meshes are made of polyvinyl alcohol and sodium alginate to form embedding granules. The method of making embedding granules is as follows: Weigh a certain amount of sodium alginate and polyvinyl alcohol into a beaker with an appropriate amount of water, heat and dissolve, then cool it to room temperature, add cellulase, cellobiase and xylose, mix well, and then mold It is made into embedding particles, and the particle size of the embedding particles is 2-6mm; then the embedding particles are put into 2 Cross-link in a saturated boric acid solution a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com