Method for extracting manganese and silverfrom oxidized manganese- silverores

A manganese-silver ore and oxidation-type technology, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve problems such as flue gas needs to be treated and discharged, and threats to the environment, so as to achieve low mineral processing costs, comprehensive utilization, and separation The effect of high selection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The oxidized manganese-silver ore was obtained from a mine in Chengde, Hebei. The multi-element analysis of the original ore is shown in Table 1.

[0011] element mn Ag Fe Al 2 o 3 CaO MgO SiO 2 Quality score, % 8.7 0.022 3.15 2.75 2.43 1.78 71.65

[0012] For the above-mentioned ores, follow the steps below to separate and extract silver and manganese and make bricks from tailings:

[0013] (1) Take 100kg of ore sample, crush and sieve to obtain ore powder with particle size less than 3mm;

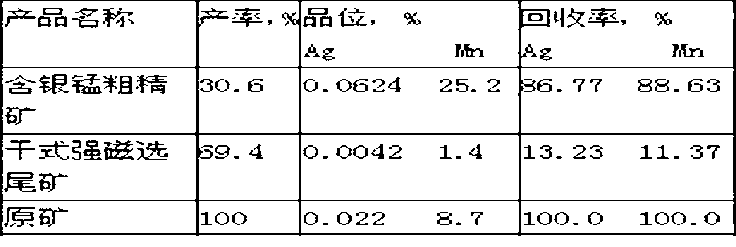

[0014] (2) Carry out magnetic separation with a dry-type strong magnetic separator with a magnetic induction of 0.8T to obtain silver-manganese rough concentrate and dry-type magnetic separation tailings. The magnetic separation results are shown in Table 2;

[0015] Table 2 Results of dry magnetic separation of ore samples

[0016]

[0017] (3) Silver-manganese coarse concentrate is wet-grinded to obtain silver-manganese coarse conce...

Embodiment 2

[0025] The oxidized manganese-silver ore was obtained from a mine in Chengde, Hebei. The multi-element analysis of the original ore is shown in Table 4.

[0026] element mn Ag Fe Al 2 o 3 CaO MgO SiO 2 Quality score, % 12.6 0.028 4.56 1.83 2.073 1.81 64.87

[0027] For the above-mentioned ores, follow the steps below to separate and extract silver and manganese and make bricks from tailings:

[0028] (1) Take 4000kg of ore samples, crush and sieve to obtain ore powder with a particle size of less than 2mm;

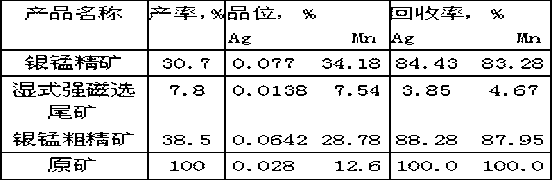

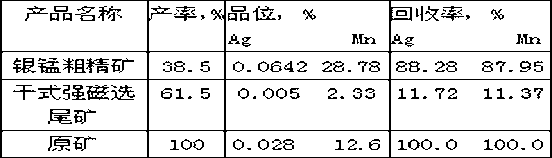

[0029] (2) Perform magnetic separation with a dry-type strong magnetic separator with a magnetic induction of 0.8T to obtain silver-manganese coarse concentrate and dry-type magnetic separation tailings. The magnetic separation results are shown in Table 5;

[0030] Table 5 Results of dry magnetic separation of ore samples

[0031]

[0032] (3) Silver-manganese coarse concentrate is wet-grinded to obtain silver-manganese coar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com