Nonmagnetic Ru film and production method thereof

A non-magnetic, thin-film technology, applied in the field of information storage, can solve the problem that the surface morphology of thin-film Ru film is not clearly stated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Described ruthenium film adopts the method for magnetron sputtering to make, and concrete preparation method comprises the following steps:

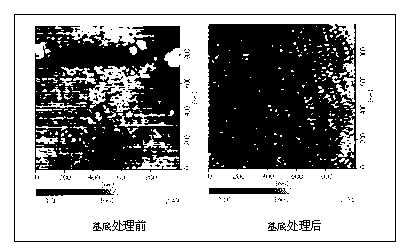

[0020] (1) Treatment of the substrate material: the (111) surface of the silicon single wafer is used as the substrate surface, and after alternating ultrasonic cleaning with acetone and ethanol, it is cleaned with ion beam pre-sputtering to remove impurities on the surface of the Si wafer. In ion beam pre-sputter cleaning, the background vacuum is better than 10 -4 Pa, the working pressure of inert gas during sputtering is 1x10 -2 Pa to 4x10 -2 Pa.

[0021] (2) Magnetron sputtering coating: Put the cleaned Si wafer into the magnetron sputtering equipment, and use a self-made Ru target for coating. Sputtering was performed at room temperature with a background vacuum of 10 -3 ~10 -4 Pa, the working pressure of Ar gas is 0.5~3Pa, the sputtering power is 50~300W, and the self-bias voltage is 100~600V.

Embodiment 1

[0024] The ruthenium thin film of the present invention is made through the following steps:

[0025] (1) Treatment of the substrate material: the (111) surface of the silicon single wafer is used as the substrate surface, and after alternating ultrasonic cleaning with acetone and ethanol, it is cleaned with ion beam pre-sputtering to remove impurities on the surface of the Si wafer. Ion beam pre-sputter cleaning with a background vacuum of 6x10 -4 Pa, the working pressure of inert gas during sputtering is 2x10 -2 Pa.

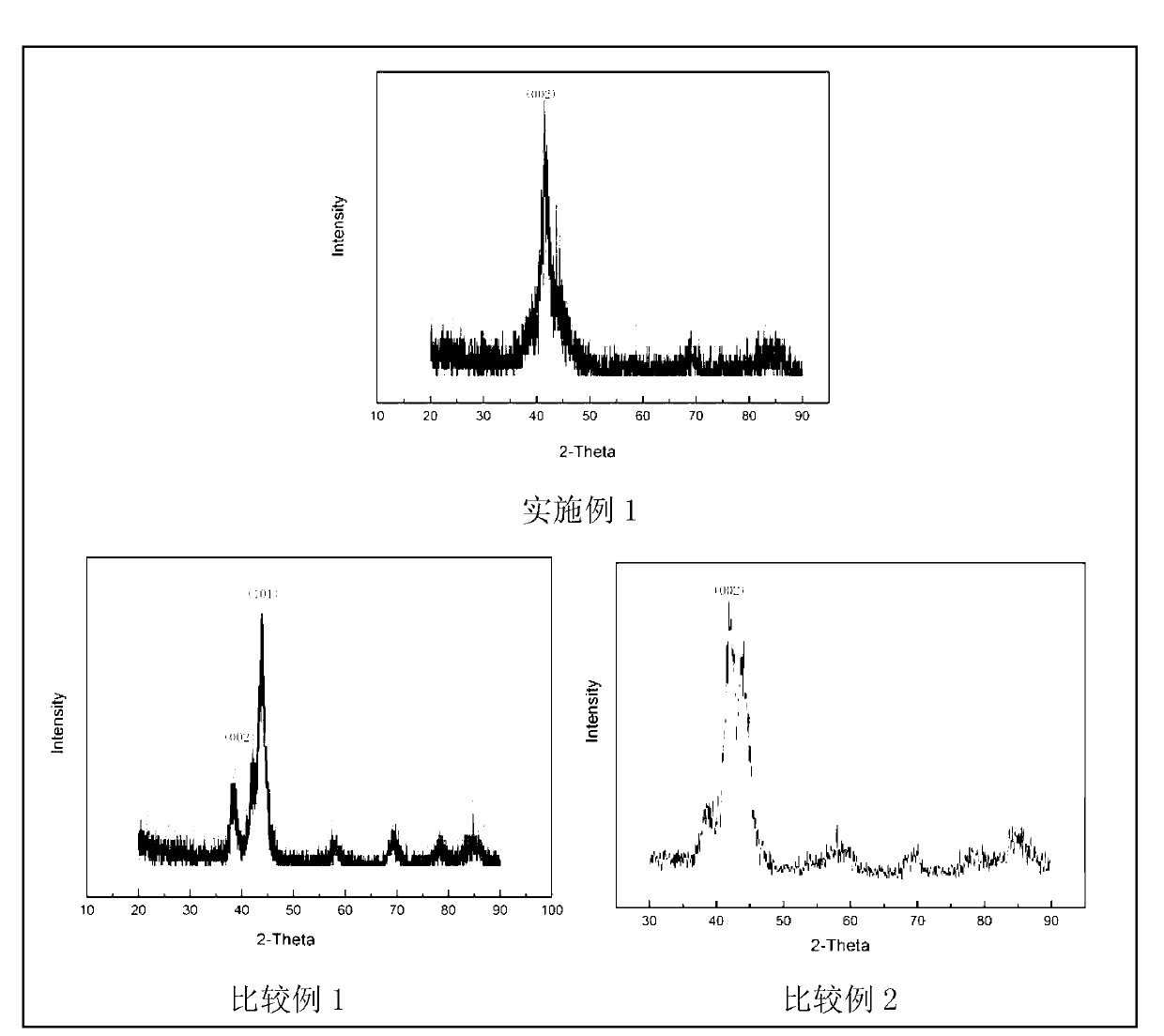

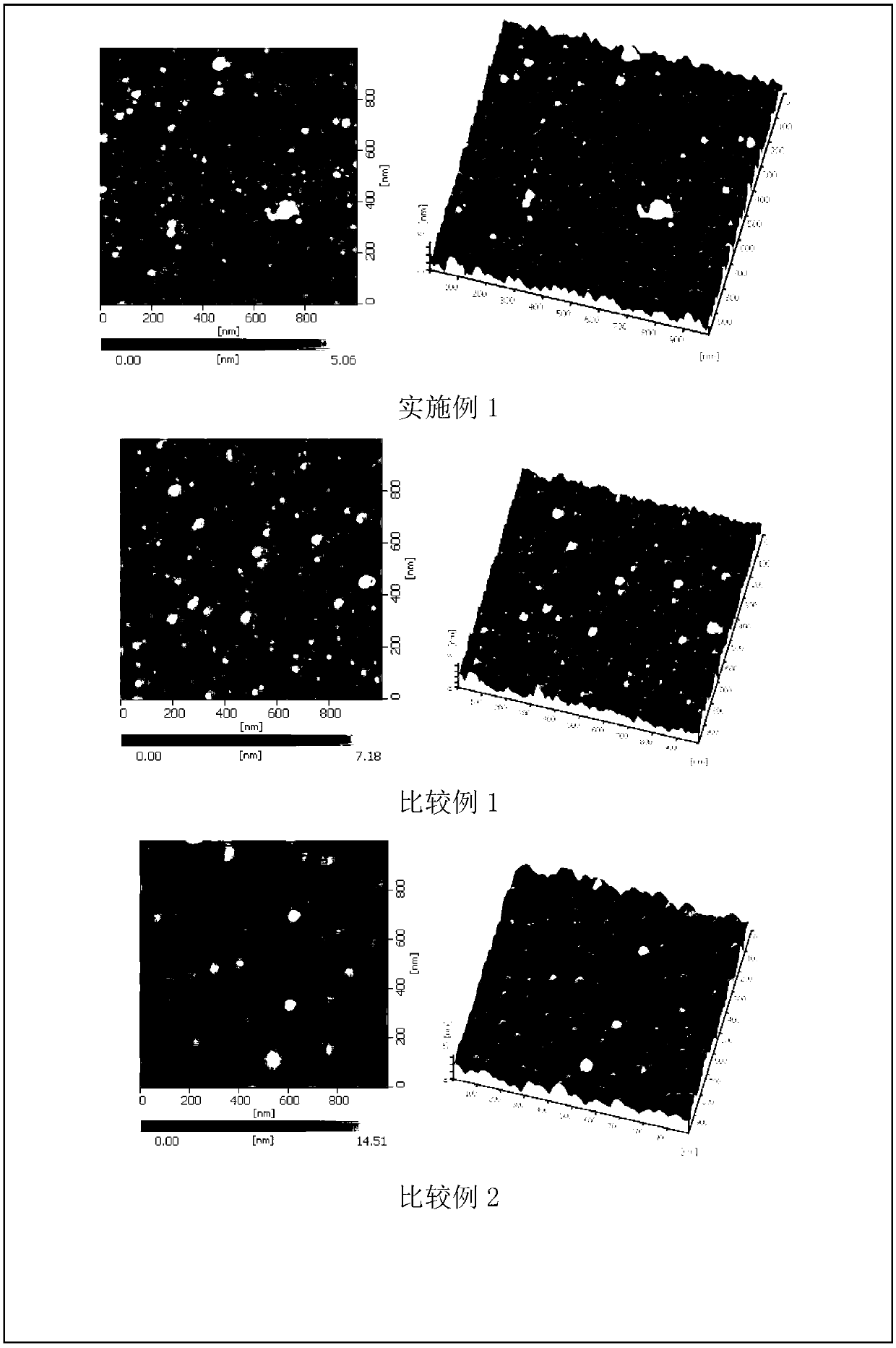

[0026] (2) Magnetron sputtering coating: Put the cleaned Si wafer into the magnetron sputtering equipment, and use a self-made ruthenium target (1#) for coating. The average grain size of the ruthenium target (1#) is 4.3 μm. In the X-ray diffraction analysis, the X-ray diffraction peak intensity ratio of the (002) crystal plane represented by the formula (1) was 42.1%. Sputtering was performed at room temperature with a background vacuum of 3x10 -3 Pa, th...

Embodiment 2

[0028] The difference from Example 1 lies in that during the magnetron sputtering coating process, the working pressure of Ar gas is 0.5Pa, the sputtering power is 300W, and the self-bias voltage is 600V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com