Oriented helical carbon nanotube fiber, preparation method and use thereof

A carbon nanotube fiber and carbon nanotube array technology, applied in the nanometer field, can solve the problems of inability to generate rotational force, low cycle life, low energy density, etc., achieve high mechanical strength and electrical conductivity, simple preparation method, fast mechanical The effect of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

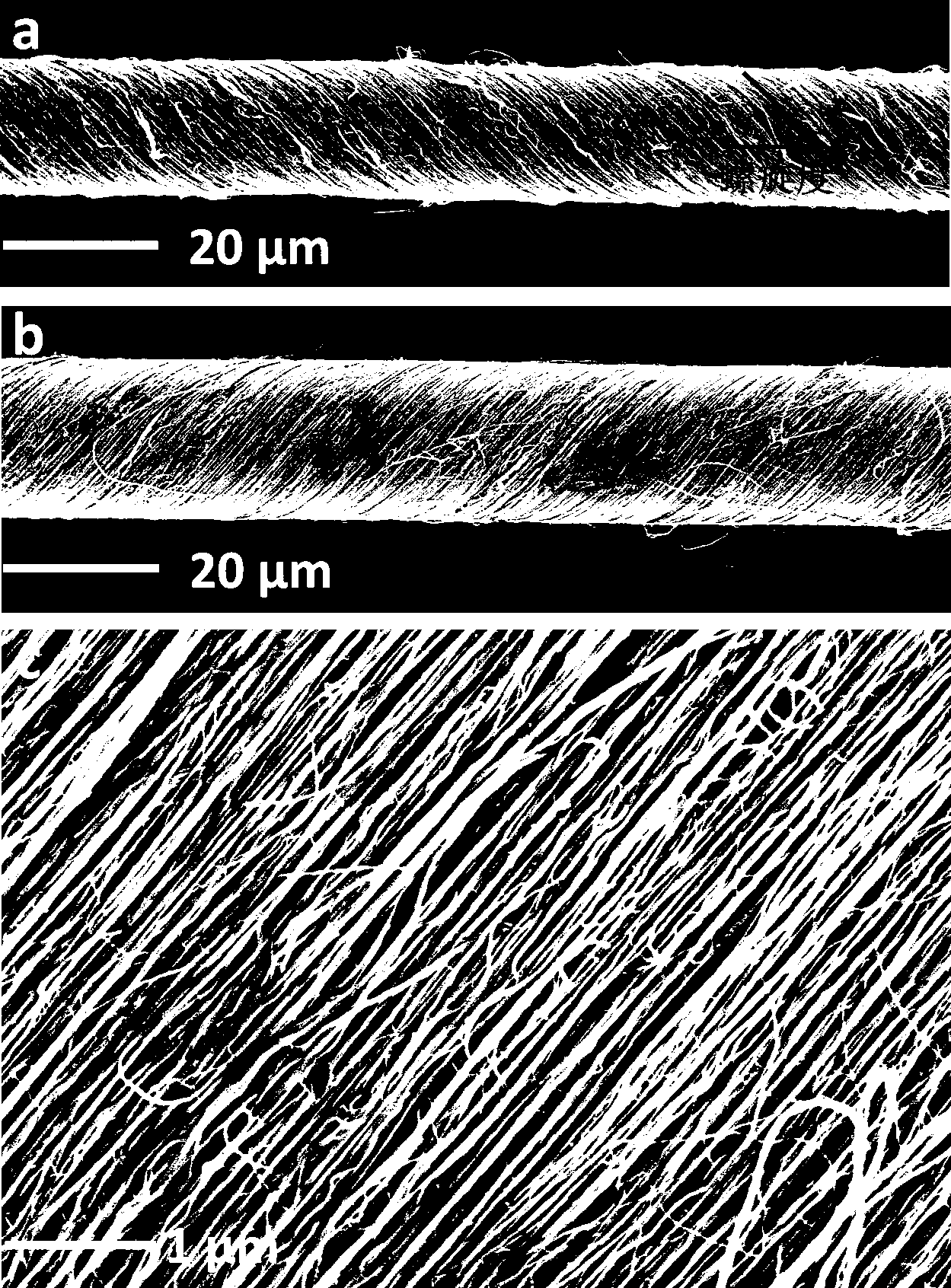

[0020] Example 1 Preparation of Aligned Helical Carbon Nanotube Fibers

[0021] (1) Synthesis of carbon nanotube arrays that can be used for spinning

[0022] Si / SiO 2 / Al 2 o 3 / Fe is the synthesis catalyst, where SiO 2 as the base, Al 2 o 3 It is a buffer layer with a thickness of 10-30 nm and a thickness of Fe of 0.5-1.5 nm. It is deposited on a silicon wafer with an electron beam evaporation coating device; in a tube furnace, ethylene is used as the carbon source, and argon and hydrogen are used as the Carrier gas, chemical vapor deposition method synthesizes highly oriented carbon nanotube arrays on the above catalyst substrate; wherein, the flow rate of ethylene is controlled to 190-290 sccm, the flow rate of argon gas is 400-620 sccm, and the flow rate of hydrogen gas is 20-48 sccm. 5-100 min to obtain spinnable carbon nanotube arrays.

[0023] (2) Synthesis of aligned helical carbon nanotube fibers

[0024] Pull out carbon nanotube ribbons from the...

Embodiment 2

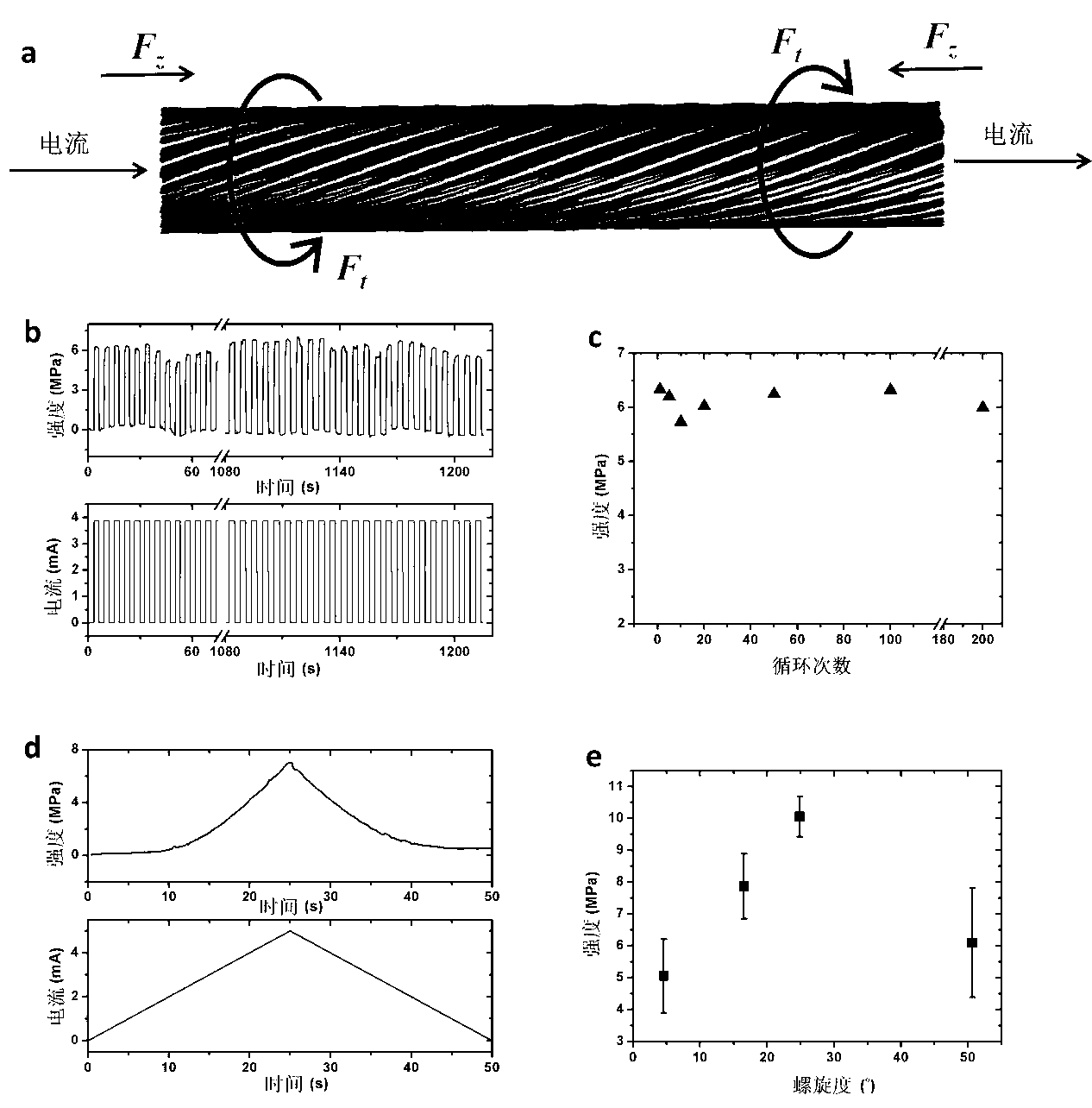

[0027] Example 2 Application of Carbon Tube Fibers in Manufacture of Artificial Muscles

[0028] The present invention has carried out the stress response experiment of carbon tube fiber in the electric current electric field, gets the length and is fixed on the tensometer on the carbon tube fiber of 5mm, carbon tube fiber two ends are glued together with a copper wire respectively with silver glue, and copper wire respectively Connect to the positive and negative poles of the power supply. Before the measurement, adjust the fiber so that it is in a just straightened state. A series of characterizations of the electrostress were performed using dextro-rotated fibers. figure 2 It is a schematic diagram of the stress generated when the carbon tube fiber passes through the current and the mechanical characterization results. figure 2 (a) is a schematic diagram of the contraction and rotation of a right-handed carbon tube fiber when an electric current passes through it....

Embodiment 3

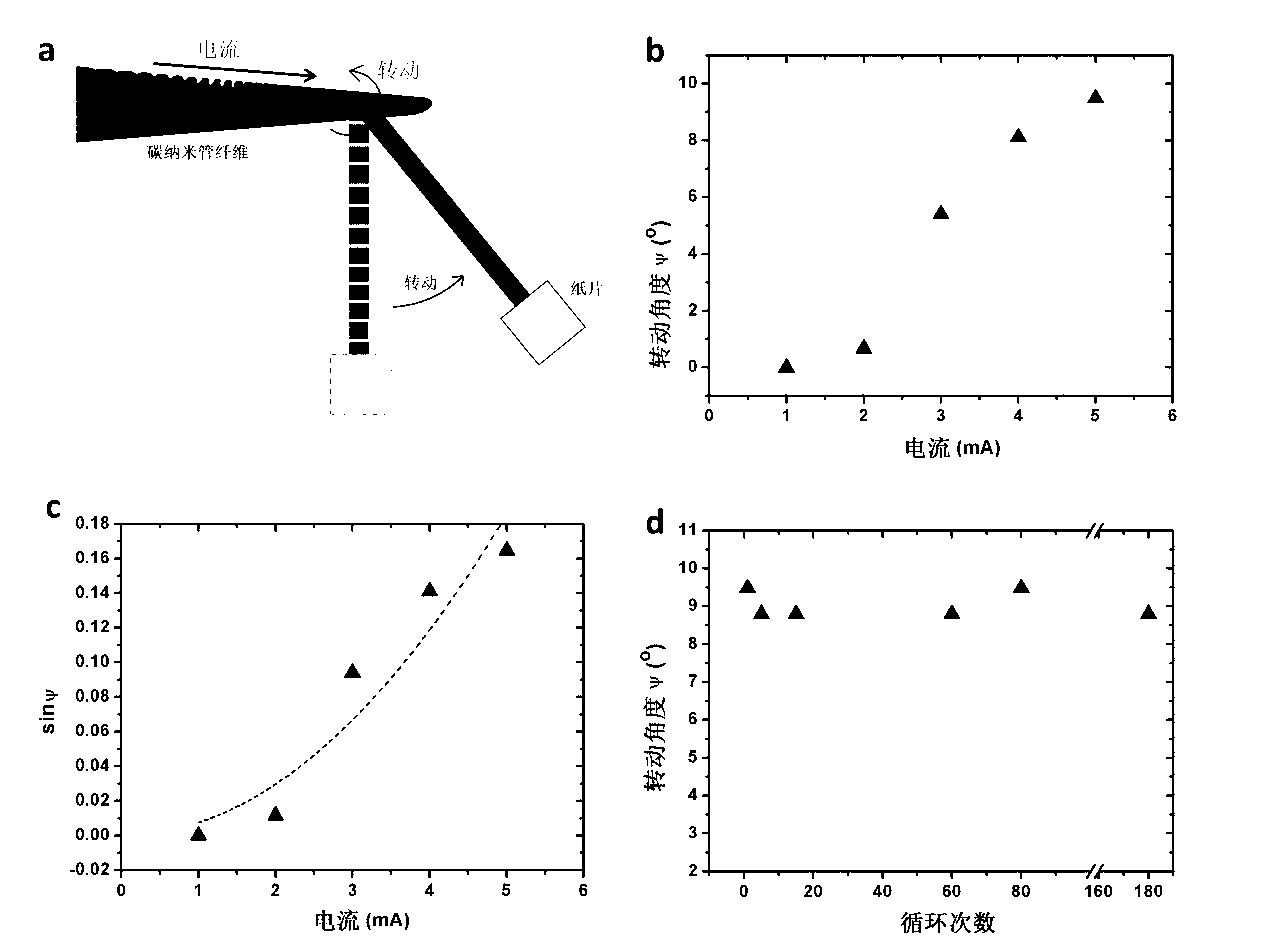

[0034] Example 3 Application of carbon tube fibers in the manufacture of electric motors

[0035] We assembled carbon tube fibers into a simple electric motor, the schematic diagram of which is shown in image 3 (a) shown.

[0036] (1) Assembly and basic operation of carbon fiber motor

[0037] A 4cm-long right-handed carbon tube fiber is suspended on a glass substrate as a "motor fiber". The left and right ends of the fiber are coated with silver glue, and connected to the external circuit by copper wire. A miniature pendulum composed of a carbon nanotube fiber of 8.5mm and a paper sheet weighing 0.302mg is connected to the right end of the suspended fiber. It is negligible compared with the sheet, so the center of mass of the whole pendulum can be regarded as the center of the sheet.

[0038] A current of 5 mA is applied to a 4 cm carbon nanotube fiber, and the left and right ends of the fiber rotate in opposite directions in the direction of increasing helicity. For the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com