Thermal storage heated brick bed capable of being warm in winter and cool in summer

A technology that is warm in winter and cool in summer and heat storage. It is used in household heating, heating methods, heating systems, etc. It can solve the problems of difficult entry of heat dissipation, uneven temperature on the kang surface, and prolonged cooking time. The effect of ash labor intensity, rapid rise in room temperature, and shortened cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

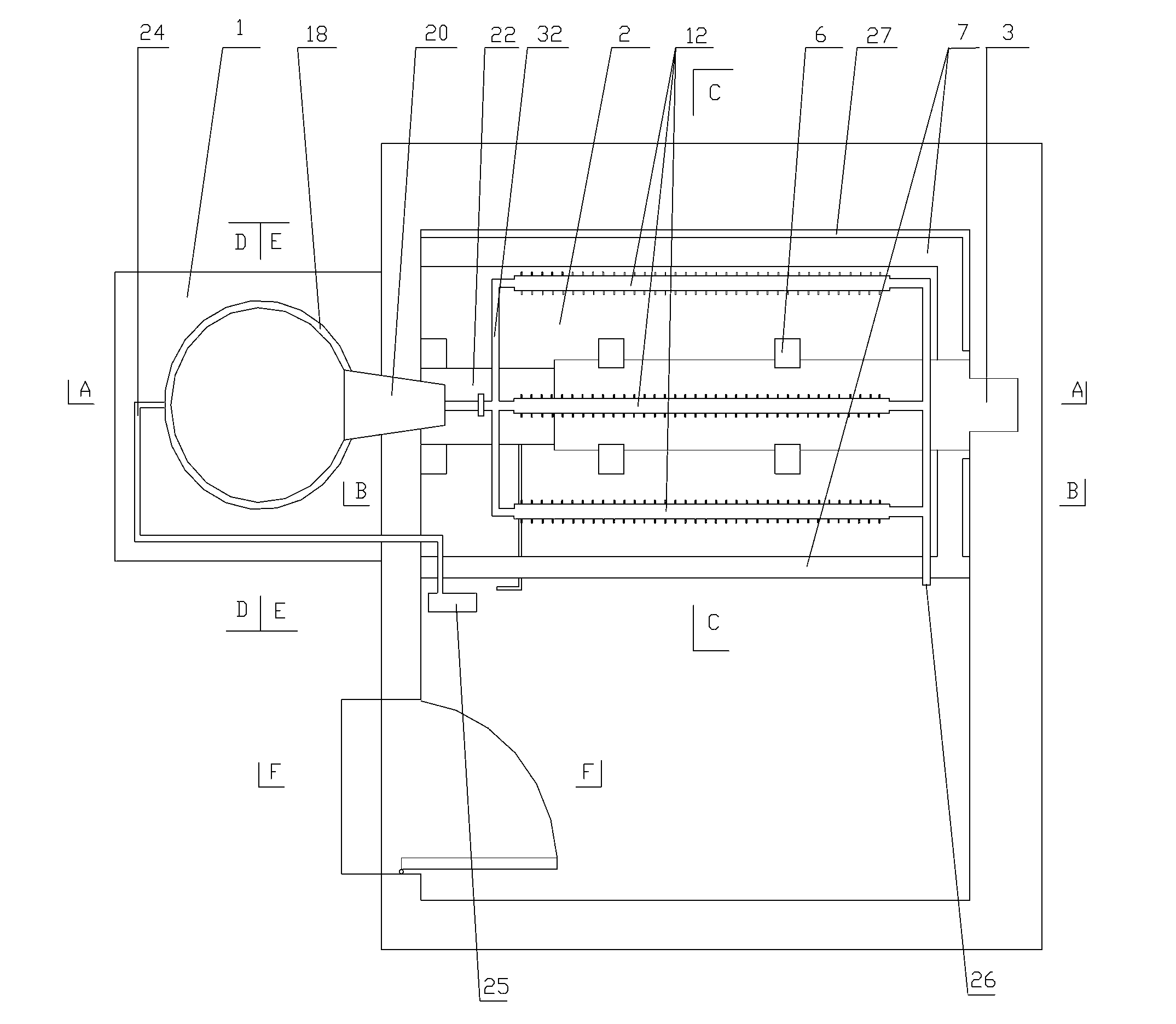

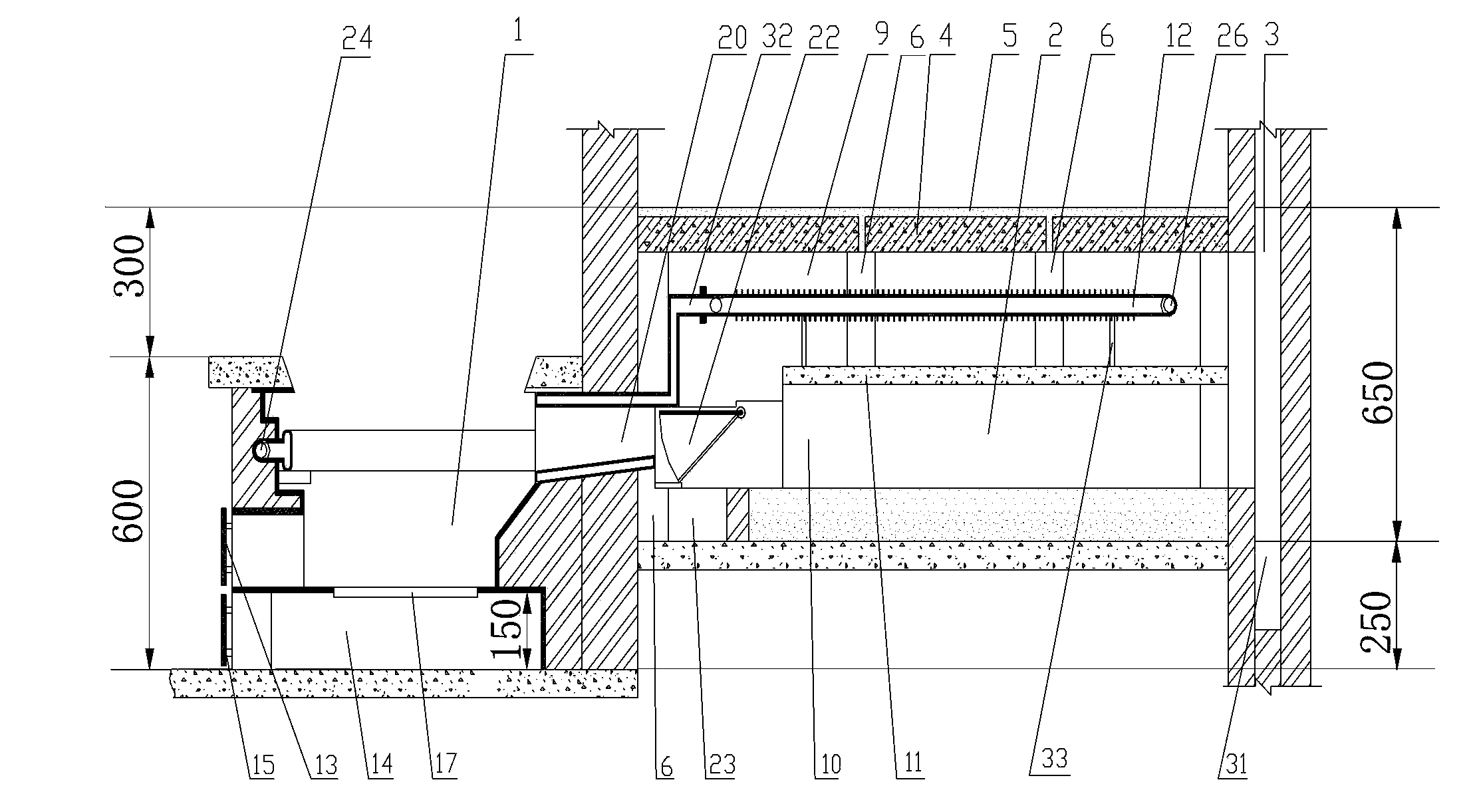

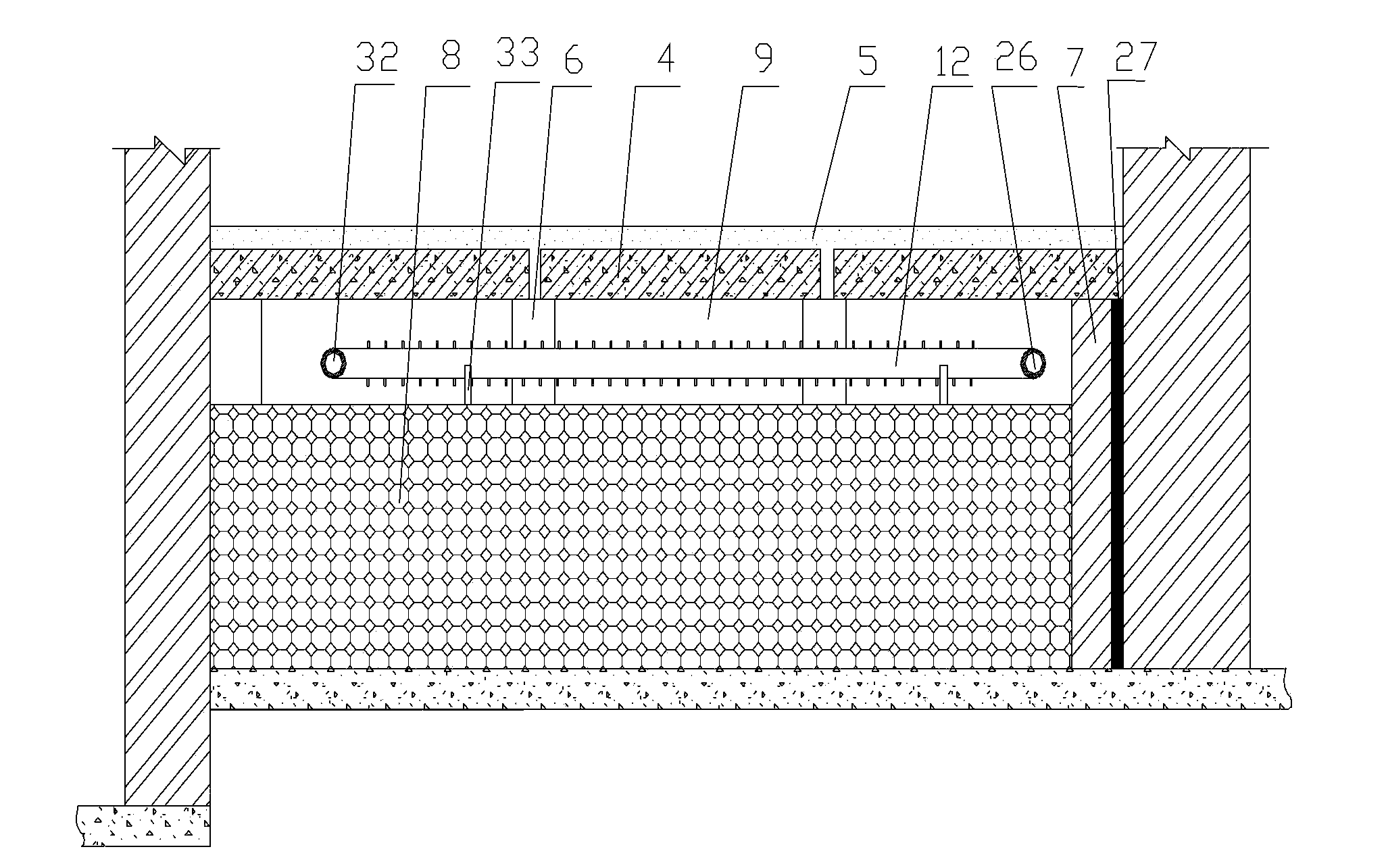

[0053] Such as figure 1 , figure 2 Shown, a kind of thermal storage heated kang which is warm in winter and cool in summer comprises three parts: a stove 1, a kang body 2 and a chimney 3. The stove 1 is a heat source body, the kang body 2 is a heat dissipation component, and the chimney 3 is a smoke exhaust component.

[0054] Heat source body comprises stove 1 and heating pipe 12, as figure 2 , Figure 5 , Figure 6 , Figure 7 As shown, the stove 1 includes a hearth 16 with a furnace door 13 and an ash chamber 14 with an ash chamber door 15, the ash chamber 14 is arranged below the hearth 16, between the hearth 16 and the ash chamber 14 A slit-type grate 17 is arranged between them; a hot air supply chamber 18 is arranged above the inside of the stove 16, and the hot air supply chamber 18 is fixedly supported by a bracket 19 of the hot air supply chamber, and the hot air supply chamber 18 It consists of an internal hollow air supply ring 21, which is fixedly connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com