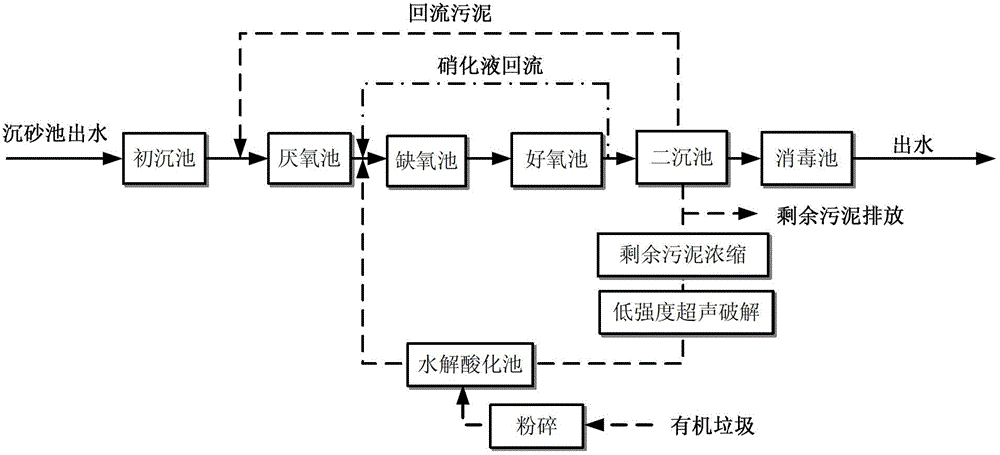

Method and application of performing hydrolytic acidification to low-intensity ultrasound pretreated sludge and organic refuse to supply carbon source for promoting bio-denitrification

An ultrasonic pretreatment, organic waste technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. Not properly disposed of and other problems, to achieve significant environmental and economic benefits, reduce operating costs, and reduce sludge production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 6%Q (Q is the influent flow rate) sludge is concentrated by gravity to a solid content rate of 2.3%, and then transported to 8 probe-type ultrasonic processors for cracking by the sludge pump. The frequency of the ultrasonic reactor is 20kHz, and the diameter of the probe is 20mm, the sound energy density is 0.38kW / m 3 , the cracking time is 3 minutes. After cracking, the TCOD in the sludge liquid phase increased by 2363 mg / L, the activity of the main hydrolase α-glucosidase in the sludge liquid phase increased by 2 times, and the protease activity increased by 3 times compared with that before cracking.

[0019] After degreasing and pulverizing, the mixture of food waste (commonly used for degreasing and crushing in waste treatment) and cracked excess sludge, the solid-to-liquid ratio is 1:15 (mass of organic waste: volume of excess sludge). The two enter the hydrolytic acidification tank for 24 hours of hydrolytic acidification reaction. After the reaction, the VFAs ...

Embodiment 2

[0021] 8%Q (Q is the influent flow rate) sludge is concentrated by gravity to a solid content rate of 2%, and then transported to 4 probe-type ultrasonic processors for cracking through the sludge pump. The frequency of the ultrasonic reactor is 28kHz, and the diameter of the probe is 25mm, the sound energy density is 0.52kW / m 3 , the cracking time is 4min. After cracking, the TCOD in the sludge liquid phase increased by 2546mg / L, the activity of the main hydrolase α-glucosidase in the sludge liquid phase increased by 2.3 times, and the protease activity increased by 3.5 times compared with that before cracking.

[0022] After degreasing and pulverizing, the mixture of food waste (commonly used for degreasing and crushing in waste treatment) and cracked excess sludge, the solid-to-liquid ratio is 1:20 (mass of organic waste: volume of excess sludge). The two enter the hydrolytic acidification tank for 30 hours of hydrolytic acidification reaction. After the reaction, the VFAs...

Embodiment 3

[0024] 10%Q (Q is the influent flow rate) sludge is concentrated by gravity to a solid content rate of 2.5%, and then transported to 6 probe-type ultrasonic processors for cracking by the sludge pump. The frequency of the ultrasonic reactor is 28kHz, and the diameter of the probe is 25mm, the sound energy density is 0.68kW / m 3 , the cracking time is 9 minutes. After cracking, the TCOD in the sludge liquid phase increased by 3078mg / L, the activity of the main hydrolase α-glucosidase in the sludge liquid phase increased by 2.6 times, and the protease activity increased by 3.8 times compared with that before cracking.

[0025] The mixture of crushed vegetable waste (commonly used in waste treatment) and the cracked excess sludge has a solid-to-liquid ratio of 1:25 (mass of organic waste: volume of excess sludge). The two enter the hydrolytic acidification tank for hydrolysis and acidification reaction for 48 hours. After the reaction, the VFAs in the mixed solution can reach 861...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com