Crop straw ensiling and method for efficiently producing biogas by ensiled straws

A crop straw and straw technology, which is applied in the field of agricultural solid waste treatment and recycling, can solve the problems of increased operating components, short straw harvest period, and huge energy consumption, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

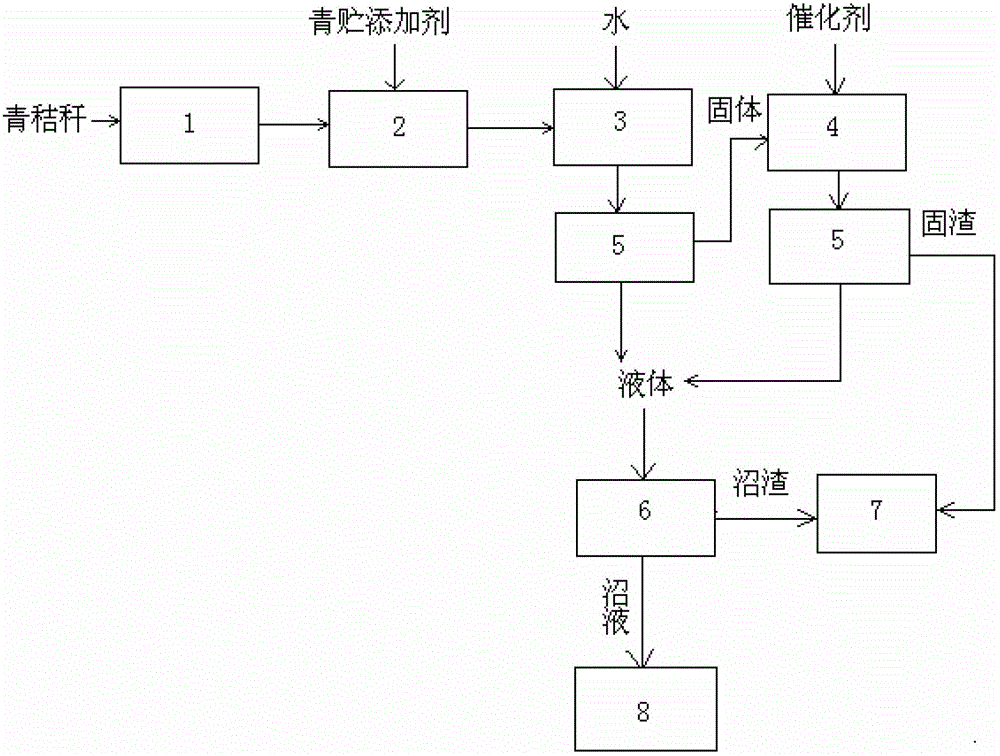

Image

Examples

Embodiment 1

[0029] The freshly harvested green straw is crushed to 10 mm, and then mixed with a nitric acid solution with a mass concentration of 2%. The weight ratio of the nitric acid solute to the green straw is 1:1000, and the mixture is placed in a storage cellar for 30 days to obtain silage straw. Mix the silage straw and water in the pool for soaking. The weight ratio of the silage straw and water is 1:20, and the soaking time is 6 hours. After soaking, the mixture is squeezed and separated. Oxygen fermentation device is used for biogas production; the separated solid is hydrothermally reacted by using sulfuric acid solution with a mass concentration of 1% as a catalyst. The weight ratio of sulfuric acid solute to solid is 1:200, the reaction temperature is 120°C, and the reaction time is 60 minutes. After the reaction is completed, the solid-liquid mixture is squeezed and separated again, and the separated liquid is diluted and adjusted, and sent to an anaerobic fermentation tank ...

Embodiment 2

[0031] The freshly harvested green straw is crushed to 20 mm, and then mixed with an ammonia solution with a mass concentration of 2%. The weight ratio of the ammonia solute to the green straw is 1:1500, and the mixture is placed in a storage cellar for 90 days to obtain silage straw. Mix the silage straw and water in the pool for soaking. The weight ratio of the silage straw and water is 1:10, and the soaking time is 8 hours. Oxygen fermentation device for biogas production; the separated solid uses nitric acid solution with a mass concentration of 0.5% as a catalyst for hydrothermal reaction, the weight ratio of nitric acid solute to solid is 1:100, the reaction temperature is 200°C, and the reaction time is 5 minutes After the reaction is completed, the solid-liquid mixture is squeezed and separated again, the separated liquid is diluted, adjusted, and then sent to an anaerobic fermentation tank to produce biogas, and the separated solid is used for aerobic composting. The...

Embodiment 3

[0033] The freshly harvested green straw is crushed to 30mm, and then mixed with 10% acetic acid solution, the weight ratio of acetic acid solute to green straw is 1:100, and the mixture is placed in a storage cellar and sealed for 60 days to obtain silage straw. Mix the silage straw and water in the pool for soaking. The weight ratio of the silage straw and water is 1:5, and the soaking time is 4 hours. Oxygen fermentation device for biogas production; the separated solid uses ferric chloride solution with a molar concentration of 0.05mol / L as a catalyst for hydrothermal reaction, the weight ratio of ferric chloride solute to solid is 1:25, and the reaction temperature is 90°C, the reaction time is 90 minutes. After the reaction is completed, the solid-liquid mixture is squeezed and separated again. The separated liquid is diluted and adjusted, and sent to an anaerobic fermentation tank to produce biogas. The separated solid is used for pyrolysis and digestion. The treated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com