Graphene-modified hard alloy, preparation technology and application thereof

A graphene modification and cemented carbide technology, applied in the field of cemented carbide and its preparation technology, can solve the problem of large difference in density between carbon powder and cemented carbide, uneven distribution of carbon content in sintered body, large particle size of original carbon powder, etc. problems, to achieve uniform carbon content, overcoming poor uniformity of addition, ultra-high mechanical strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

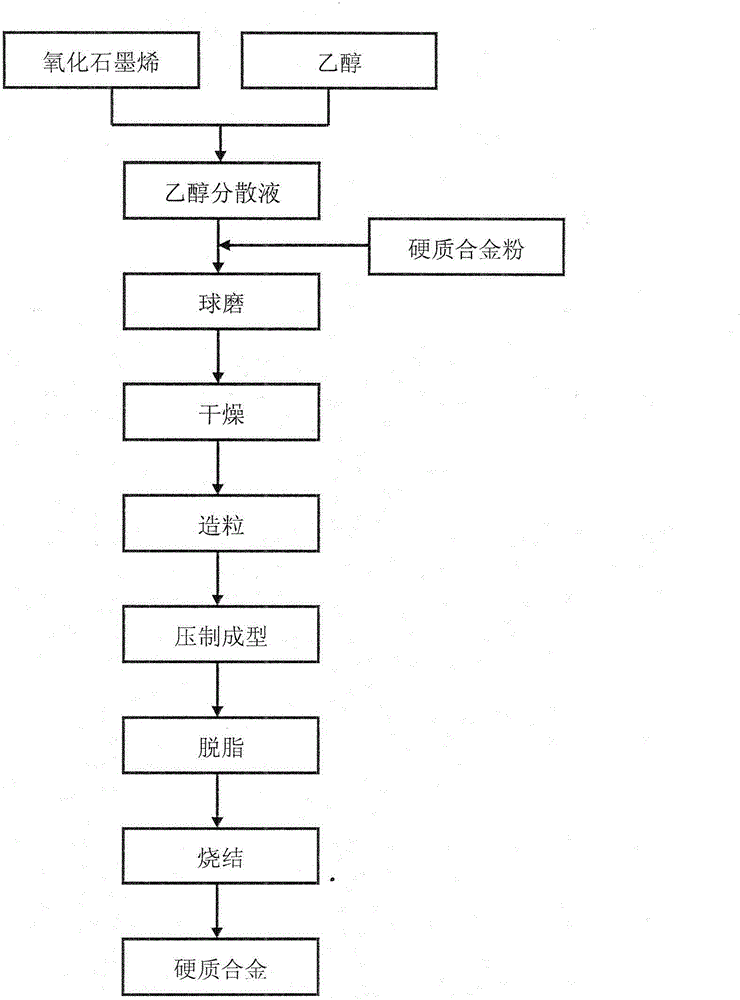

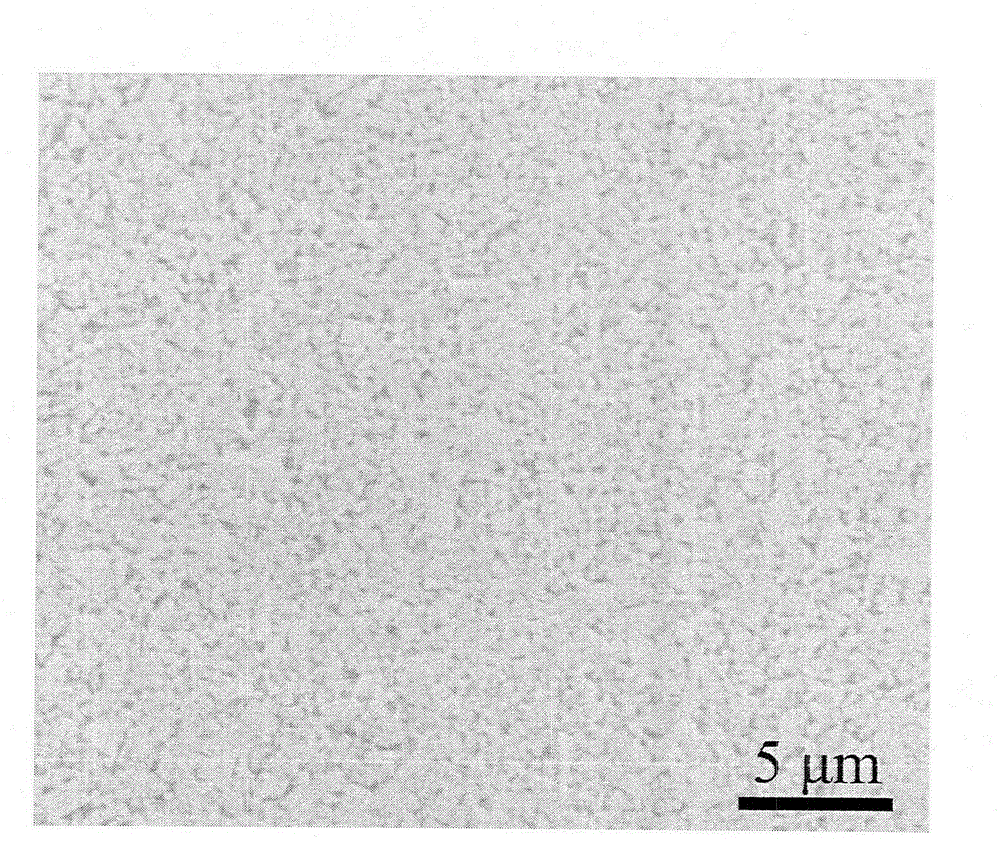

[0036] Example 1: Graphene oxide, which accounts for 0.5% of the weight of the cemented carbide powder, is dispersed in ethanol by ultrasonic, then the YG8 cemented carbide powder is added and mixed, ball milled in a planetary ball mill at 200 rpm for 24 hours, then vacuum-dried and mixed with 3wt % polyvinyl alcohol binder granulation, 350 MPa compression molding, 0.5 ℃ / min heating to 350 ℃ degreasing for 3 hours, 1350 ℃ vacuum sintering densification, obtained graphene modified cemented carbide, its structure and mechanical properties see performance figure 2 and Table 1.

Embodiment 2

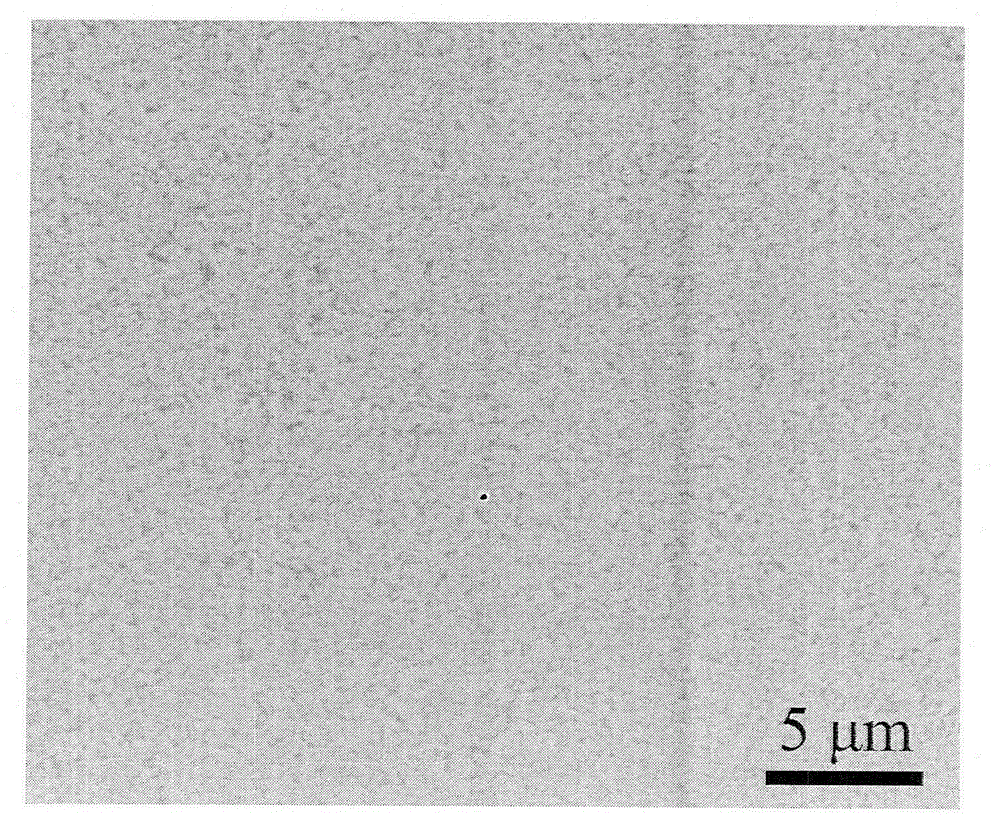

[0037] Example 2: The difference between this embodiment and embodiment 1 is that the amount of graphene oxide added is 0.25% of the weight of the cemented carbide powder, and its structure and mechanical properties refer to image 3 and Table 1.

Embodiment 3

[0038] Example 3: The difference between this example and Example 1 is that the amount of graphene oxide added is 0.75% of the weight of the cemented carbide powder, and its mechanical properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com