Rear earth-contained high-permeability Ni-Fe soft magnetic alloy, preparation method and purposes thereof

A technology of soft magnetic alloy and high magnetic permeability. It is applied in the field of nickel-iron alloy and nickel-iron soft magnetic alloy. It can solve the problems of unmentioned magnetic properties, achieve good alloying effect, improve comprehensive magnetic properties and mechanical properties, and Effect of the original microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

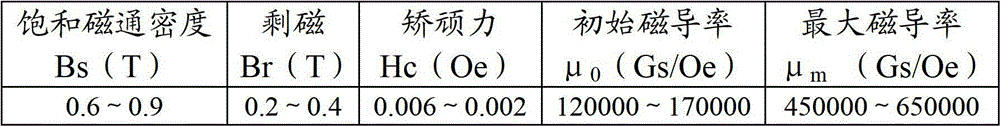

Image

Examples

Embodiment Construction

[0042] Below, the present invention will be further described in detail in conjunction with examples.

[0043] ingredients

[0044] According to the preparation method of the rare earth-containing high magnetic permeability Ni-Fe soft magnetic alloy of the present invention, the ingredients are distributed according to the following ingredients, and the chemical composition is by weight percentage: nickel (Ni) 40-83%, manganese (Mn) 0.38-0.56%, Silicon (Si) 0.2~4.0%, molybdenum (Mo) 3.0~5.7%, copper (Cu) 2.0~8.2%, rare earth element Re0.02~15%, Re is rare earth element gadolinium (Gd), terbium (Tb), At least one of dysprosium (Dy), samarium (Sm) and praseodymium (Pr), carbon < 0.015%, phosphorus < 0.015%, sulfur < 0.015%, the rest is iron and unavoidable impurities.

[0045] to smelt

[0046] Using a vacuum induction furnace (VIM) for semi-continuous production of electrodes and ingots, the required melting power is 575kVA, and it takes about 75 minutes to melt 1000Kg of mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com