Dead lactobacillus biomass for antimicrobial use and a production method therefor

A technology of lactic acid bacteria and antibacterial substances, applied in the directions of biochemical equipment and methods, medical raw materials derived from bacteria, medical preparations containing active ingredients, etc. Excellent antibacterial activity, the effect of inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

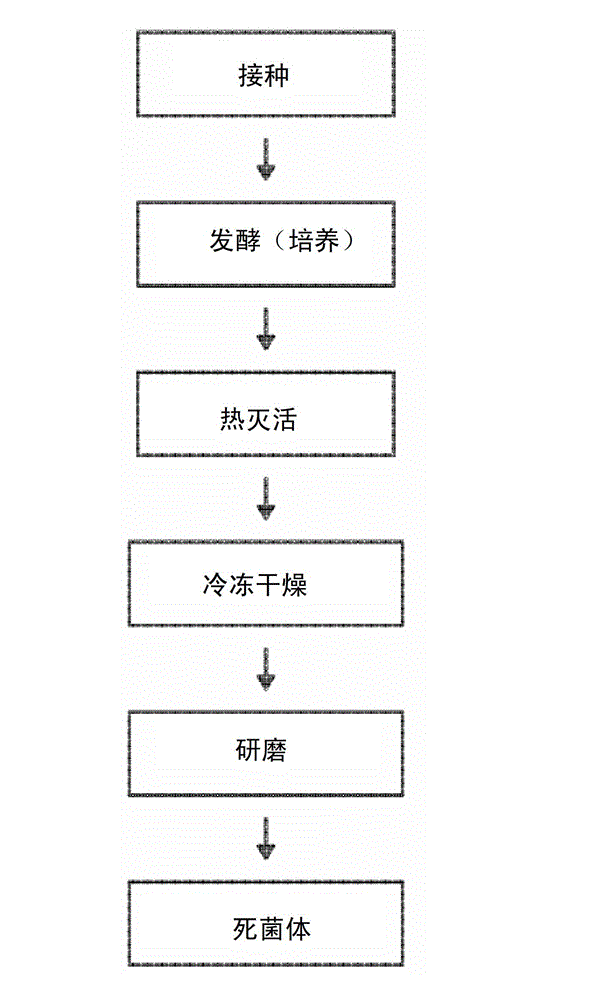

[0082] Such as Figure 5 As shown, the method for preparing heat-inactivated dead lactic acid bacteria freeze-dried product of the present invention is adopted.

[0083] Specifically, the complete fermentation broth was separated into a fermentation filtrate and a solution containing lactic acid bacteria using a centrifuge at 7,260 RPM. Transfer the fermentation filtrate to a pressure vessel (fermenter), heat inactivate at 90°C for 10 minutes, cool to 40°C, repeat heat inactivation at 110°C for 10 minutes, cool to 40°C, and use a fluidized bed dryer A 2-fold (2X) concentration using soy protein isolate and powdered skim milk as absorbents yields a heat-inactivated and dried fermentation filtrate.

[0084] Mix the solution containing lactic acid bacteria, dilute it with purified water at a ratio of 1:2, and heat inactivate it at 121°C for 20 minutes in a steam autoclave. Based on the solution containing heat-inactivated dead lactic acid bacteria, use 20% by weight of Trehalos...

Embodiment 2

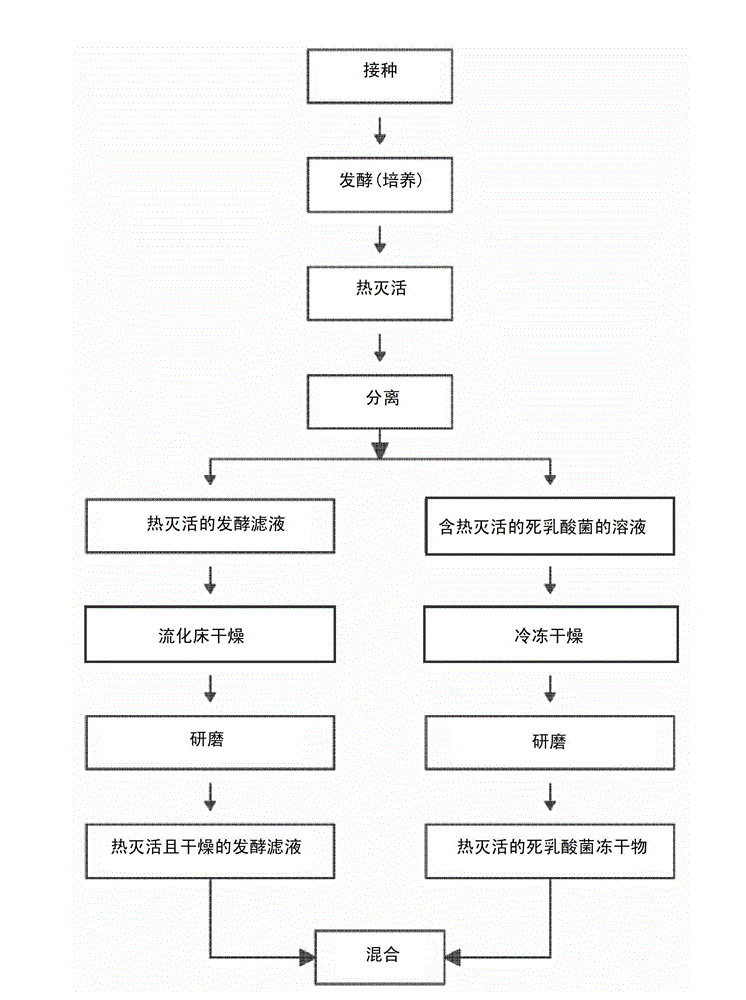

[0086] Such as figure 2 As shown, the method for preparing heat-inactivated dead lactic acid bacteria freeze-dried product of the present invention is adopted.

[0087] The complete fermentation broth of lactic acid bacteria is heat-inactivated at 90°C for 10 minutes, cooled to 40°C, repeated heat-inactivated at 110°C for 10 minutes, cooled to 40°C, and then separated into lactic acid bacteria containing heat-killed dead lactic acid bacteria by centrifuge solution and heat-inactivated fermentation filtrate. Then, the heat-inactivated fermentation filtrate was concentrated twice (2×) by using a fluidized bed dryer, and soybean protein isolate and powdered skim milk were used as absorbents, thereby obtaining a heat-inactivated and dried fermentation filtrate.

[0088] Use trehalose and starch based on 20% by weight of the heat-inactivated dead lactic acid bacteria solution as a cryoprotectant at room temperature to coat the solution containing heat-inactivated dead lactic acid...

Embodiment 3

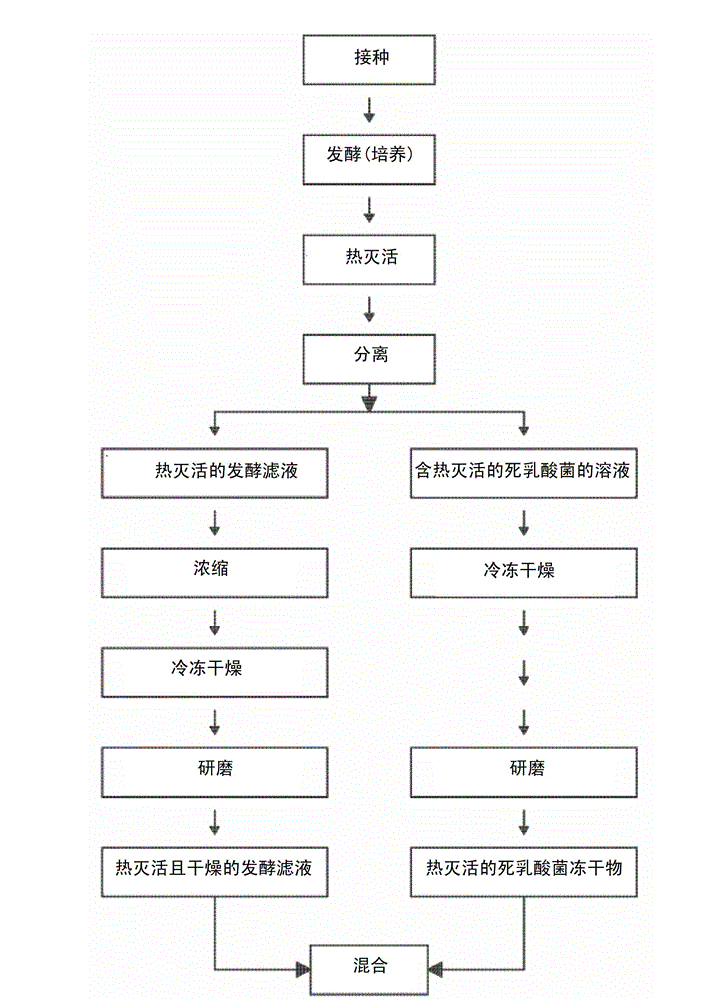

[0090] Such as image 3 As shown, the method for preparing heat-inactivated dead lactic acid bacteria freeze-dried product of the present invention is adopted.

[0091] Heat inactivate the complete fermentation broth of lactic acid bacteria at 90°C for 10 minutes, cool to 40°C, repeat heat inactivation at 110°C for 10 minutes, cool to 40°C, and use a centrifuge to separate it into heat-inactivated dead lactic acid bacteria solution and heat-inactivated fermentation filtrate. Then, using an evaporator (concentrator) to carry out 5 times (5×) concentration of the separated heat-inactivated fermentation filtrate, using 20% by weight of soybean protein isolate and powdered skimmed milk based on the heat-inactivated fermentation filtrate as absorbents, Freezing in a freezer at -40°C or below for 48 hours, freeze-drying in a freeze dryer for 96 hours, and grinding, thereby preparing a heat-inactivated and dried fermentation filtrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com