Mesotrione water dispersible granules and method for preparing same

A technology of mesotrione and dispersible granules is applied in the fields of botanical equipment and methods, herbicides, algicides, biocides, etc. problems such as poor stability, to achieve the effects of low cost, improved control efficiency, and low packaging requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

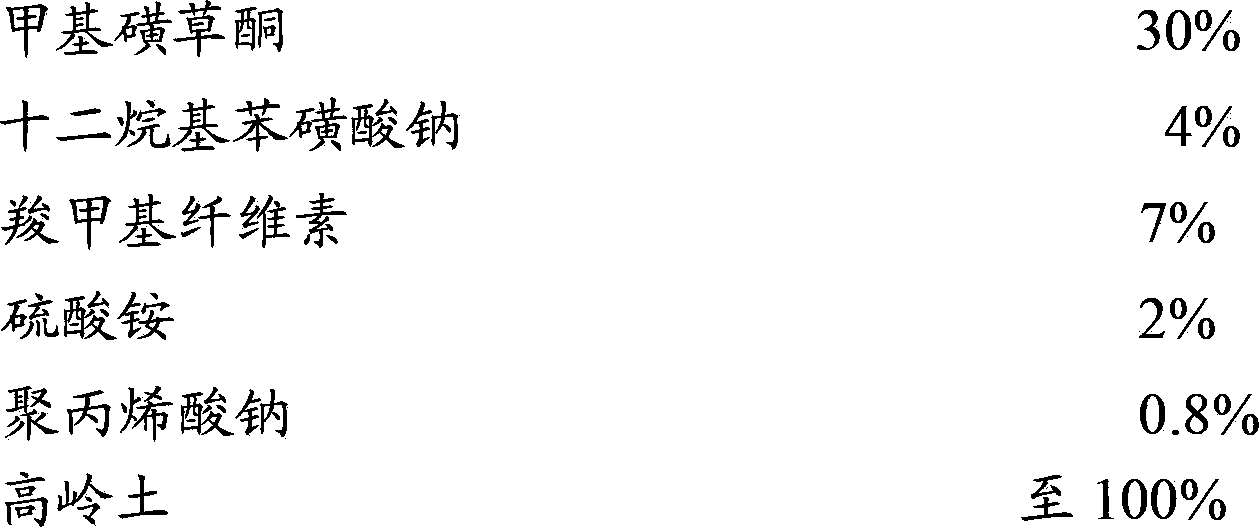

[0032] Embodiment 1: 30% mesotrione water-dispersible granule

[0033]

[0034] According to the above formula, the materials are pulverized by airflow, then mixed evenly and kneaded with water, extruded and granulated by a granulator, dried and sieved to obtain the product.

[0035] Determination of physical and chemical properties:

[0036] Moisture content 2.0%, particle size detection 99.5% through 75μm mesh, suspension rate 92%, wettability ≤ 1min, dispersibility 90%, persistent foaming (1min) 10ml, accelerated thermal storage stability qualified. It meets the quality and technical indicators of water-dispersible granules.

Embodiment 2

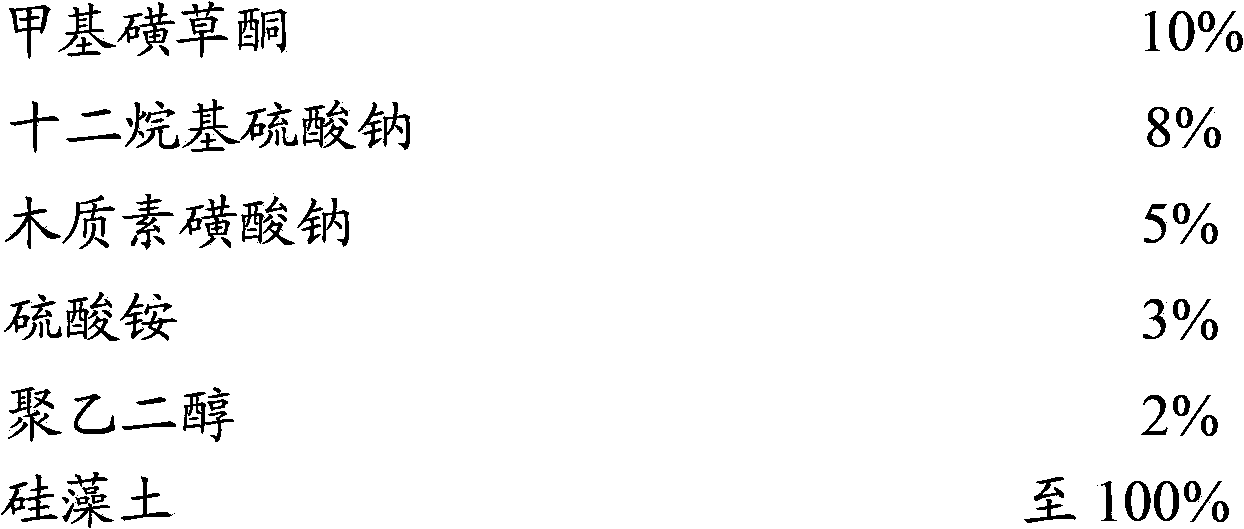

[0037] Embodiment 2: 10% mesotrione water-dispersible granule

[0038]

[0039] According to the above formula, the airflow pulverizes each material, puts it into the fluidized bed, sprays atomized water through the spray gun above the fluidized bed, and the powder boiled by the airflow contacts with water evenly, and naturally forms as the fluidized bed wall rolls down. Granules, the product.

[0040] Determination of physical and chemical properties:

[0041] Moisture content 2.0%, particle size detection 99.5% through 75μm mesh, suspension rate 92%, wettability ≤ 1min, dispersibility 90%, persistent foaming (1min) 10ml, accelerated thermal storage stability qualified. It meets the quality and technical indicators of water-dispersible granules.

Embodiment 3

[0042] Embodiment 3: 25% mesotrione water-dispersible granule

[0043]

[0044] According to the above formula, the materials are pulverized by airflow, then mixed evenly and kneaded with water, extruded and granulated by a granulator, dried and sieved to obtain the product.

[0045] Determination of physical and chemical properties:

[0046] Moisture content 2.0%, particle size detection 99.5% through 75μm mesh, suspension rate 92%, wettability ≤ 1min, dispersibility 90%, persistent foaming (1min) 10ml, accelerated thermal storage stability qualified. It meets the quality and technical indicators of water-dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com