MnO2-doped composite magnetic nanometer adsorbent, its preparation method and its application

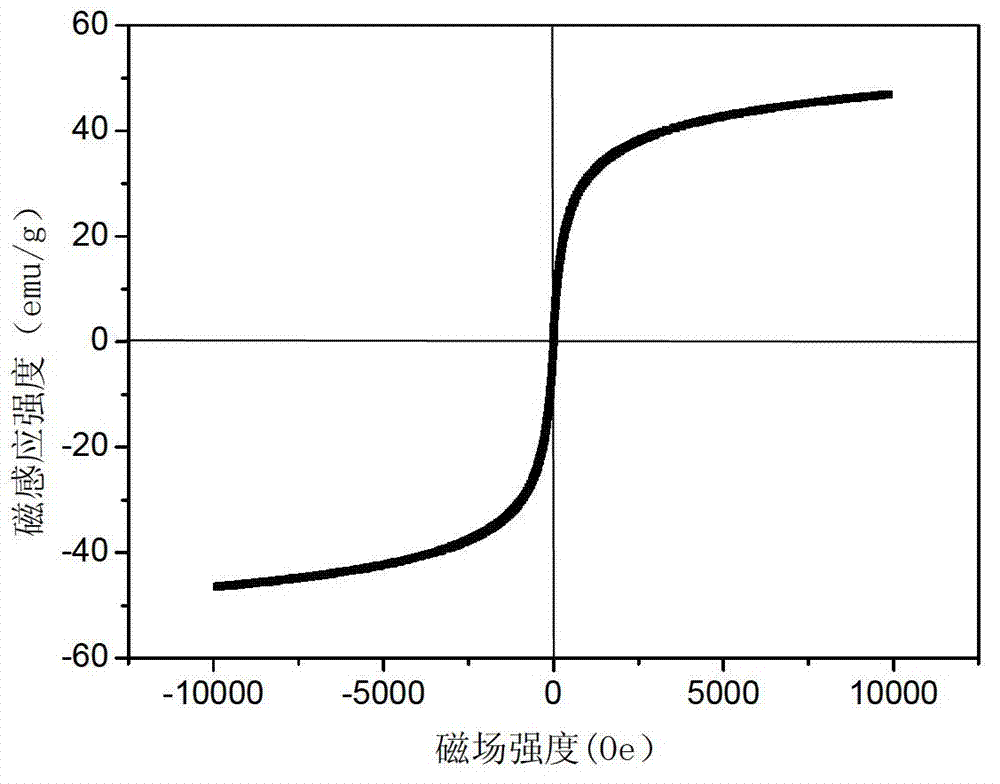

A manganese dioxide and adsorbent technology, which is applied in chemical instruments and methods, alkali metal compounds, adsorption water/sewage treatment, etc., can solve the problems of limited application and popularization of arsenic removal materials, poor removal of trivalent arsenic, and small arsenic adsorption capacity and other problems, to achieve excellent water purification performance, good removal effect, fast adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

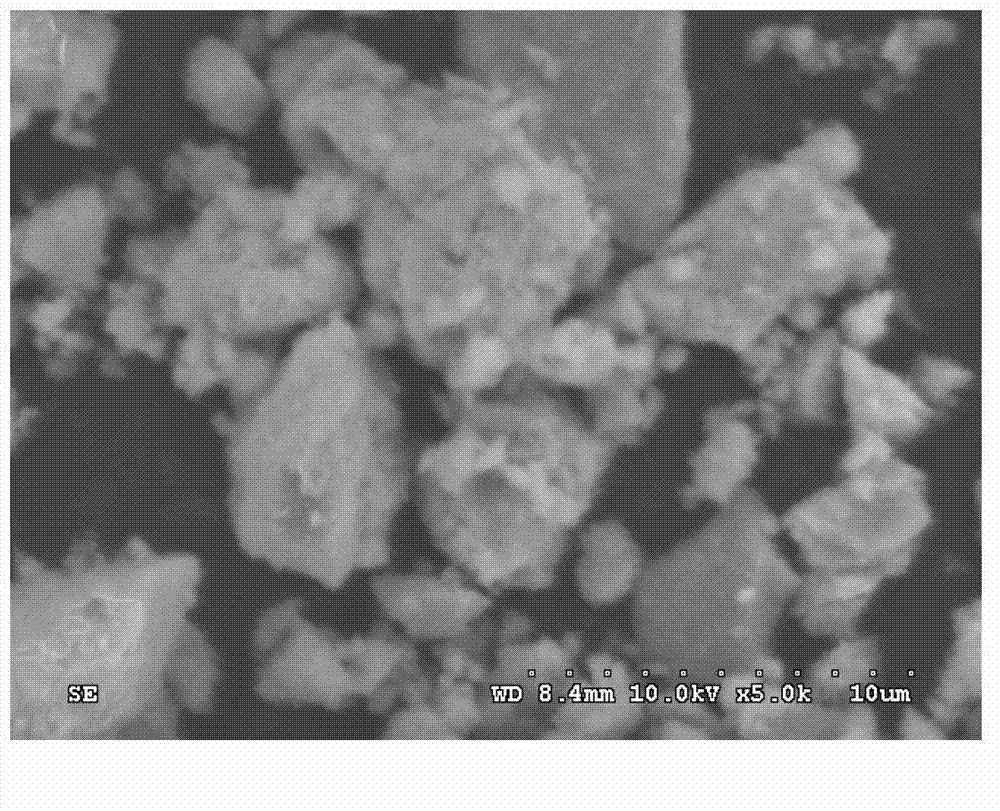

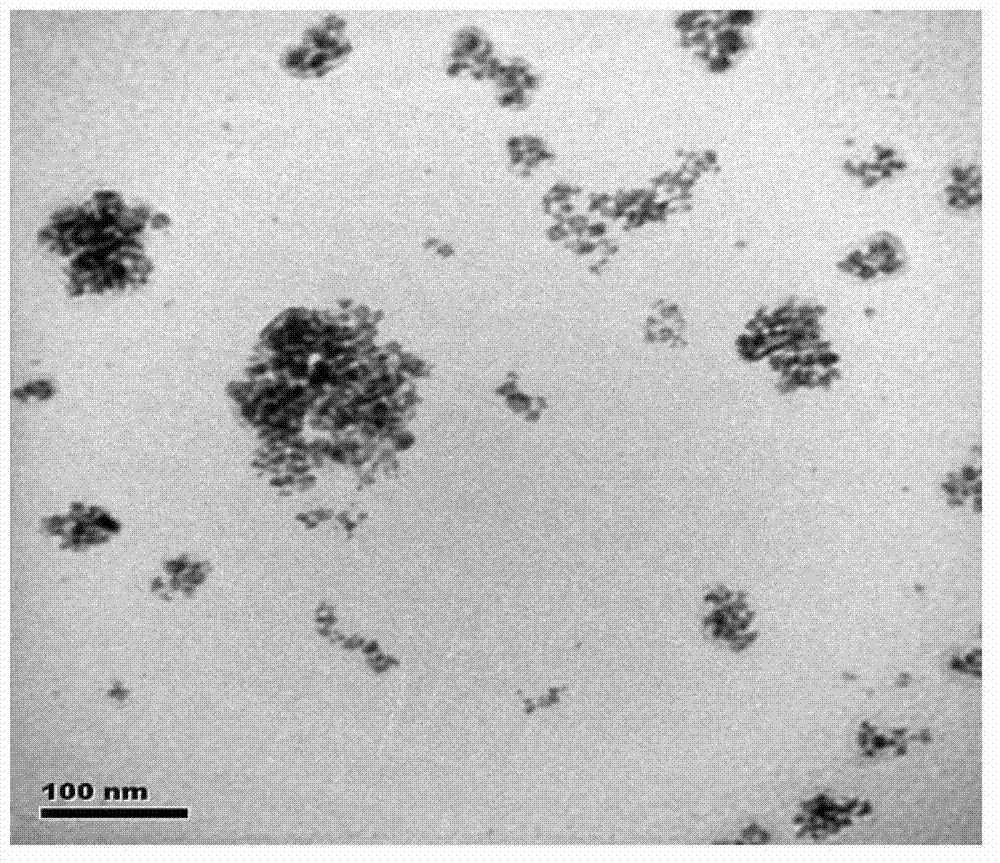

[0037] Accurately weigh 5.58g of FeCl 3 ·6H 2 O, 2.53 g FeCl 2 4H 2 O, 0.79 g MnCl 2 4H 2 O is dissolved in the beaker that fills 150ml deionized water, adds ammoniacal liquor while stirring, until solution pH is 9, at this moment in the solution, black particle is produced, continues to add deionized water, settles to 200ml, gets mixed solution, will Pour the mixture into a 1L three-necked flask, stir it in a 50°C water bath at 850rpm for 1 hour, put the mixture in a 70°C incubator and age it for 2 hours, then use a magnet to separate the black particles from the mixture and deionize Rinse with water and filter with filter paper until the pH value of deionized water after cleaning is 5-7, dry the obtained black particles at 40°C for 24 hours, take them out and grind them, and roast the black powder at 250°C for 2 hours to obtain the product.

Embodiment 2

[0039] Accurately weigh 5.58g of FeCl 3 ·6H 2 O, 4.10 g FeCl 2 4H 2 O, 0.04 g MnCl 2 4H 2O is dissolved in the beaker that fills 150ml deionized water, adds ammoniacal liquor while stirring, until solution pH is 11, at this moment black particle is produced in solution, continues to add deionized water, settles to 200ml, gets mixed solution, will Pour the mixed solution into a 1L three-neck flask, stir in a 75°C water bath at 850rpm for 3h, then put the mixed solution in a 25°C incubator to age for 2h, then use a magnet to separate the black particles from the solution, and deionized water Rinse and filter with filter paper until the pH of deionized water after washing is 5-7, dry the obtained black particles at 100°C for 4 hours, take them out and grind them, and roast the black powder at 400°C for 0.5h to obtain the product.

Embodiment 3

[0041] Accurately weigh 5.4g of FeCl 3 ·6H 2 O, 1.44g of Fe(NO 3 ) 2 ·6H 2 O, 0.0396 g MnCl 2 4H 2 O, dissolve with deionized water, add potassium hydroxide while stirring, adjust the pH to 6, black particles are produced in the solution, add deionized water, and set the volume to 500ml to obtain a mixed solution, which is placed in a 25°C water bath , stirred for 3 hours, aged the mixture in a 70°C incubator for 2 hours, then separated the black particles from the mixture with a magnet, rinsed the black particles with deionized water, and filtered with filter paper until the cleaned deionized water The pH value is 5-7, the obtained black particles are dried at 100°C for 4 hours, then ground into powder, and the black powder is calcined at 400°C for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com