Integrated chip of micro thermal conductive detector and manufacturing method for same

A thermal conductivity detector and integrated chip technology, used in the manufacture of microstructure devices, semiconductor/solid-state device components, instruments, etc., can solve the problem of poor structural strength, easy to be affected by airflow, short service life, etc. problems, to achieve the effect of not easy to be affected by airflow, concentrated heat distribution, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

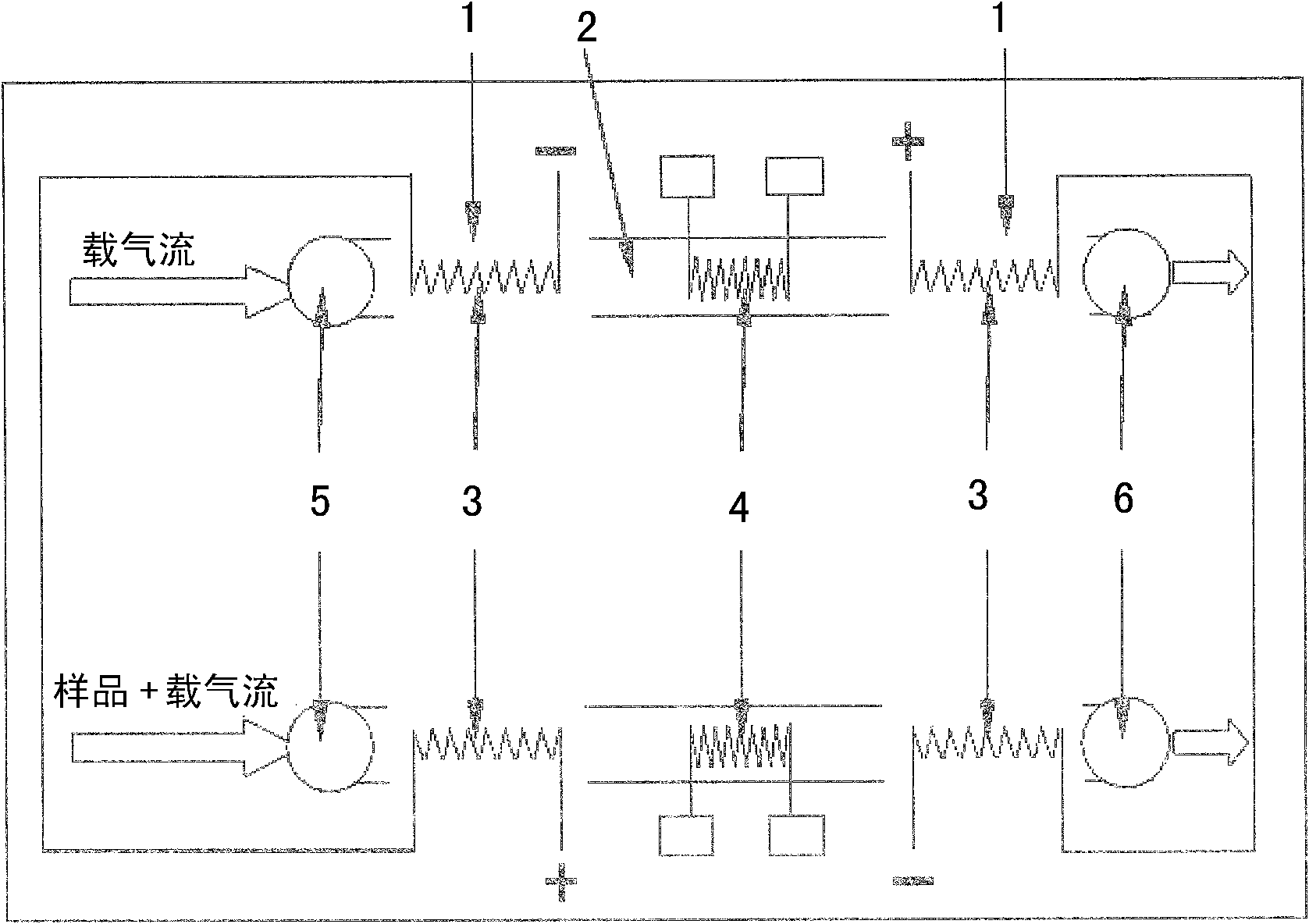

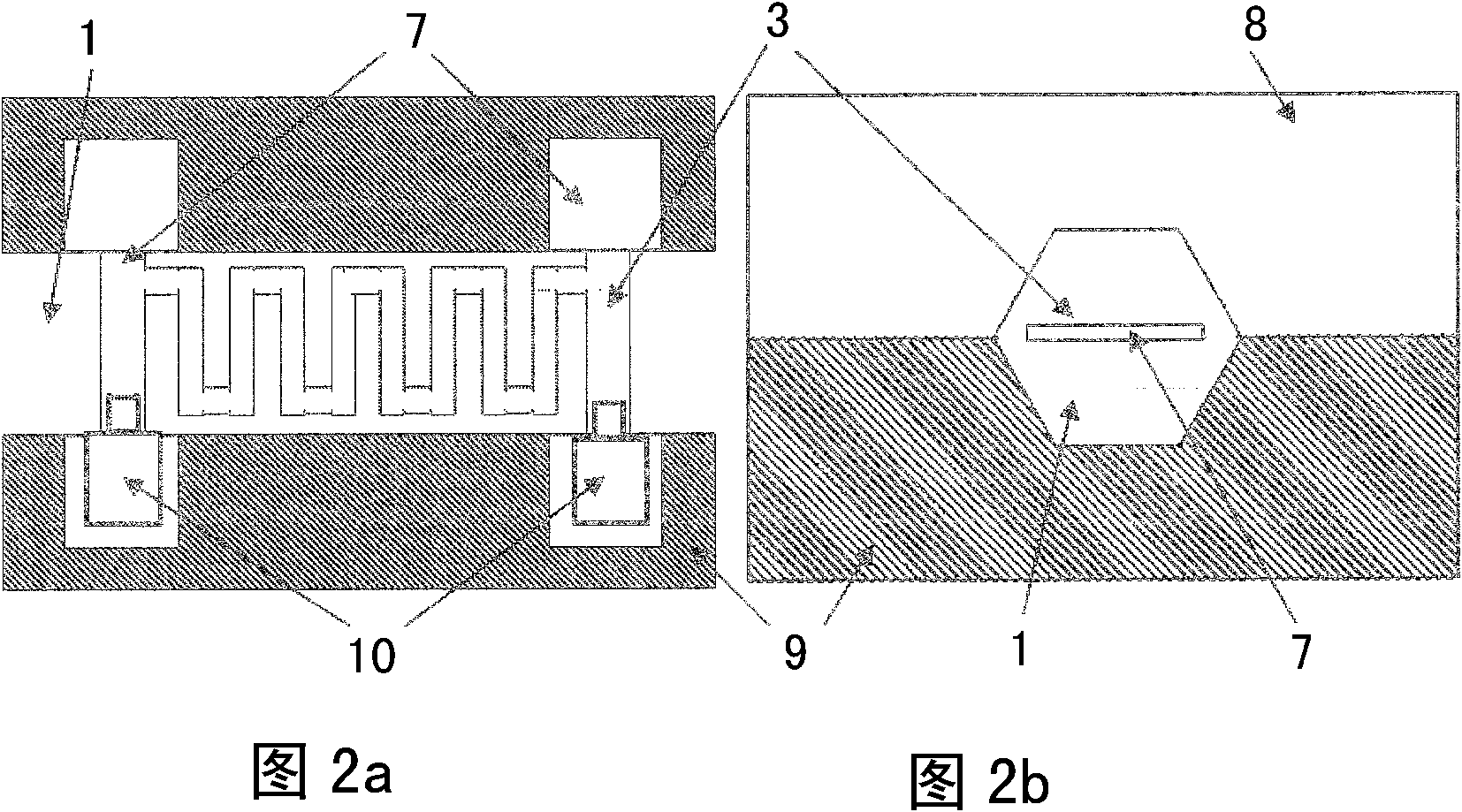

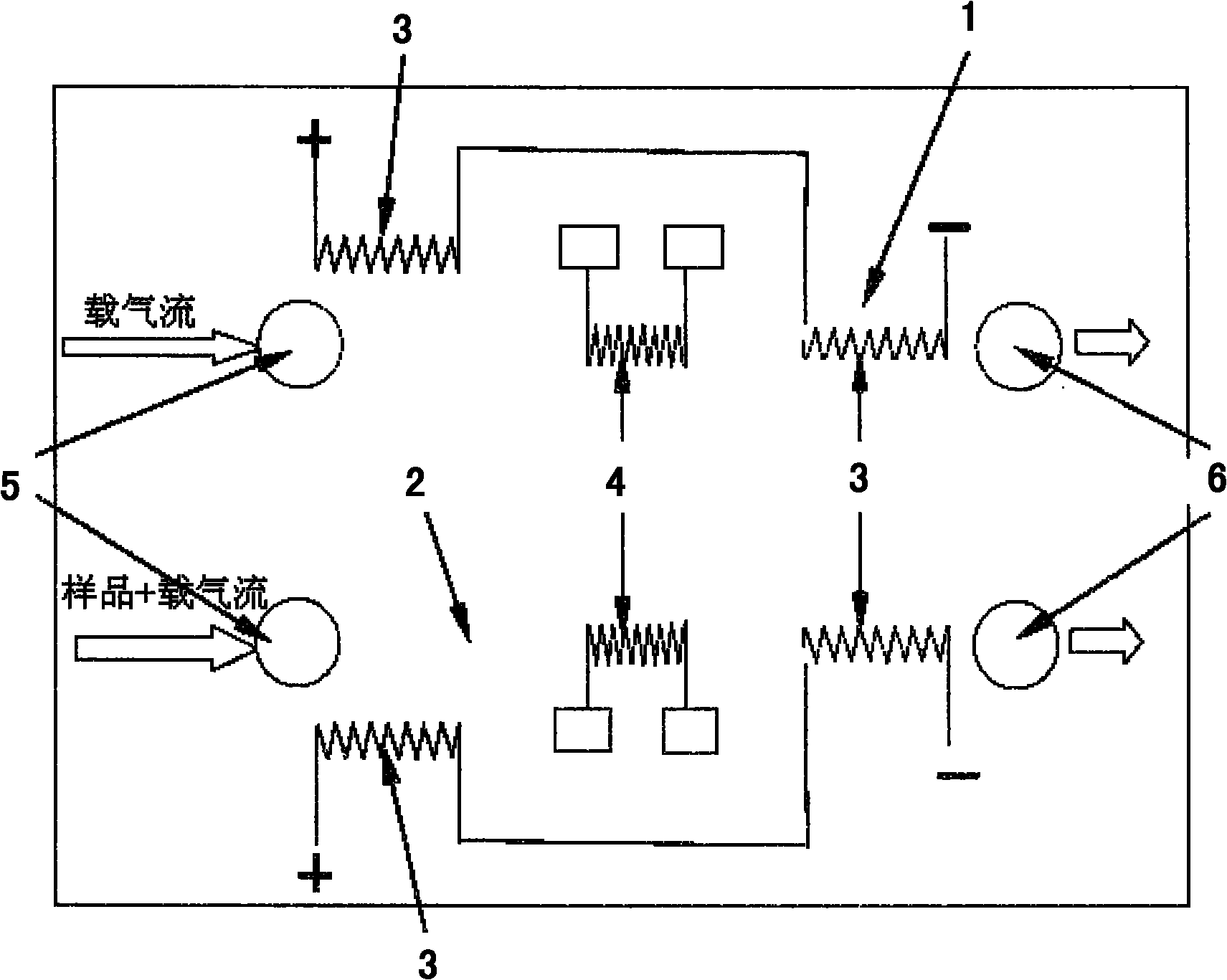

[0050] See figure 1 , 2, a kind of miniature thermal conductivity detector integrated chip and manufacturing method of the present invention are applied to the detection of various mixed gases. The thermistor 3 and the miniature temperature sensor 4 are integrated, and the manufacturing process is as follows: the integrated chip of the miniature thermal conductivity detector uses glass or silicon as substrates 8 and 9, and firstly forms microgrooves on the silicon substrate 9 by deep etching or chemical etching. Road 2 and the micro-thermal conduction pool body, and then form a suspended silicon oxide-silicon nitride-diffused silicon three-layer structure support beam 7 in the pool body, or a silicon oxide-silicon nitride double-layer structure support beam 7, Then form the miniature thermistor 3 of miniature thermal conductivity detector and miniature temperature sensor 4 on the upper surface of support beam 7 with Pt or PTC or NTC or other thermosensitive materials, then on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com