Preparation method of hyperbranched polyurethane/polyacrylate damping material

A technology of hyperbranched polyurethane and polyacrylate, which is applied in the field of preparation of hyperbranched polyurethane/polyacrylate damping materials, can solve the problems of unreported hyperbranched polyurethane/polyacrylate LIPN, etc., and is beneficial to large-scale production, The effect of low viscosity and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present invention will be further described below in conjunction with embodiment. The content involved in the present invention is not limited to the following examples. Embodiment 1: Preparation of hydroxyl-terminated hyperbranched polyurethane

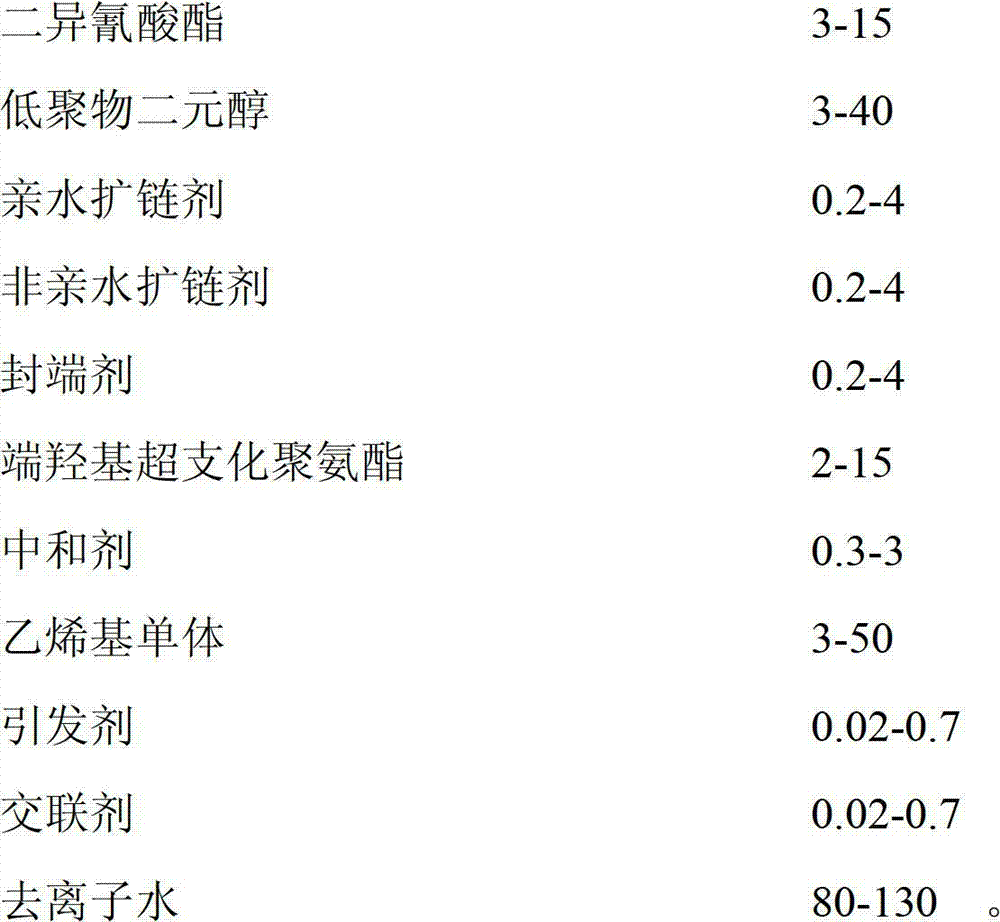

[0035] 1. The composition of each raw material is as follows in terms of parts by mass:

[0036]

[0037] 2. Specific preparation process:

[0038] Weigh IPDI and DMPA and dissolve in N,N′-dimethylformamide (DMF), stir evenly, pass nitrogen into the system, remove the air in the system, raise the temperature to 85°C for 1.5h, then cool down to -5~0 ℃, slowly drop the DMF solution of DEOA, continue to stir for 30min after the dropwise addition, then raise the temperature to 60℃ for 2.0h, and obtain hyperbranched polyurethane (HBPU) through vacuum distillation. Its number average molecular weight was determined to be 3912 by vapor pressure osmosis (VPO).

Embodiment 2

[0040] Each raw material is constituted as follows by mass parts:

[0041]

[0042] 1. Preparation of polyurethane prepolymer

[0043] Add TDI and N210 (relative molecular mass 1000) into the three-necked flask, pass nitrogen to remove the air in the system, react at 80°C for 2.5 hours, then add DMPA and BDO, react at 75°C for 2.5 hours; cool down to 60°C, add HEMA Partial end-capping reaction was carried out for 1.5 hours to obtain a polyurethane prepolymer.

[0044] 2. Preparation of hyperbranched waterborne polyurethane prepolymer

[0045] Add HBPU to the polyurethane prepolymer prepared in step 2, react at 75°C for 2 hours to obtain a hyperbranched waterborne polyurethane prepolymer, and add a small amount of acetone to reduce the viscosity of the system.

[0046] 3. Polymerization reaction

[0047] Add 1 / 3 of St and 1 / 3 of BA to the hyperbranched polyurethane prepolymer prepared in step 2 below 45°C, stir for 20 minutes, add TEA for neutralization reaction for 15 mi...

Embodiment 3

[0050] Each raw material is constituted as follows by mass parts:

[0051]

[0052] The preparation method is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com