Surface coating material for cathode material of lithium ion battery and preparation method

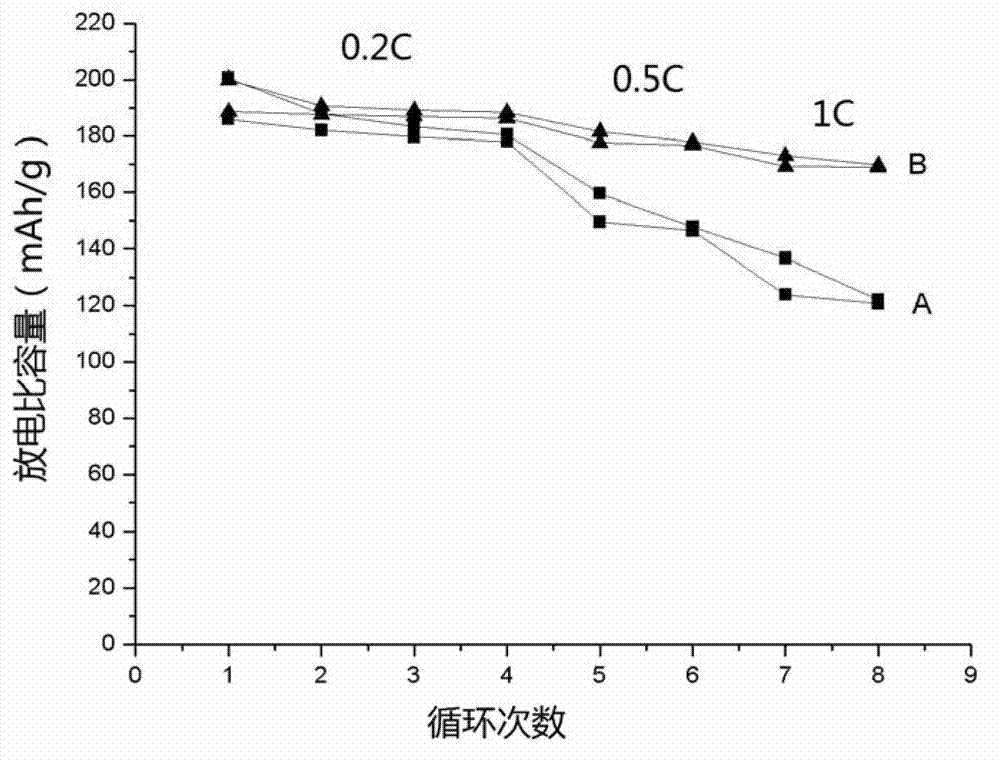

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of inability to improve the material platform and initial efficiency, no effective measures to control the hydrolysis rate, uneven coating, etc., and achieve improvement. The effect of cycle performance and rate capability, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Measure 1.7mL ethyl acetoacetate (CH 3 COCH 2 COOC 2 H 5 ), dissolved in 50mL ethanol and stirred for 1h. Measure 4.8mL of n-butyl titanate (C 16 H 36 O 4 Ti) is added to the above solution. After continuous stirring for 2h, 2.132g of aluminum nitrate (Al(NO 3 ) 3 ) And 0.094g of lithium nitrate (LiNO 3 ). After stirring to fully dissolve, 0.24 mL of deionized water was added dropwise, stirred to fully hydrolyze, and left to stand to obtain a sol. Weigh 30g lithium cobalt oxide (LiCoO 2 ) Put into a beaker, measure 30mL of ethanol into it, and stir evenly; Measure 2.3mL of sol into lithium cobaltate dropwise, slowly heat to 60℃, continue to stir to volatilize the ethanol, and then put it in the oven drying. Put the dried materials into the muffle furnace and calcine at 750°C for 5 hours.

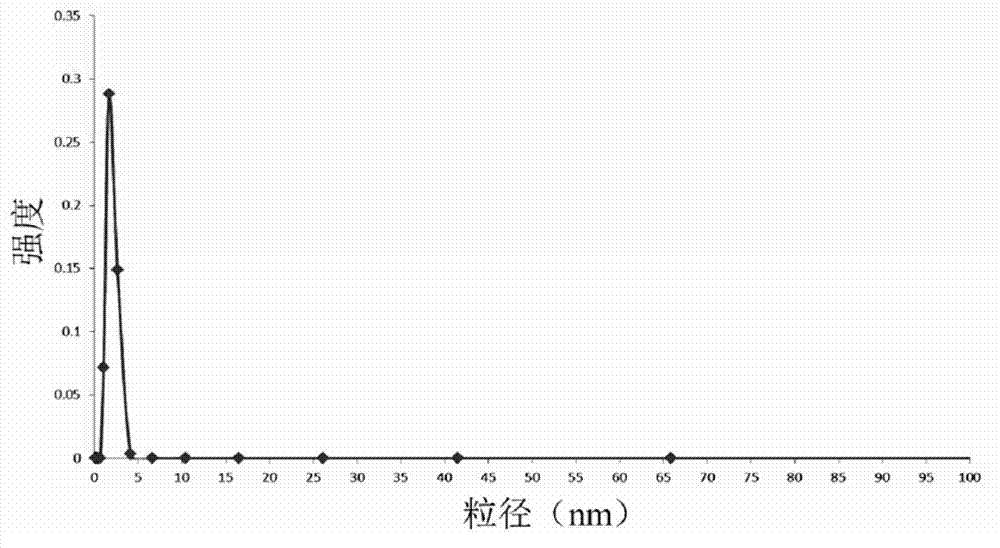

[0028] DLS analysis of the obtained titanium aluminum lithium mixed sol, the results are as follows figure 1 Shown. From figure 1 It can be seen that the particle size of the prepare...

Embodiment 2

[0031] Measure 5mL ethyl acetoacetate (CH 3 COCH 2 COOC 2 H 5 ), add 10 mL of n-butyl titanate and stir thoroughly with a magnetic stirrer to obtain liquid A. Measure 400 mL of deionized water, add 5.552 g of aluminum nitrate and add 3 drops of concentrated nitric acid (65%) dropwise, and stir well to obtain liquid B. Add liquid B to liquid A slowly, and continue to stir to obtain a sol. Weigh 10 g of lithium cobalt oxide, add 20 mL of deionized water, and stir; measure 2.9 mL of sol and add it dropwise to the lithium cobalt oxide. After stirring for 2 hours, perform suction filtration, and then put the material in an oven for drying. Put the dried materials into a muffle furnace and calcinate at 800°C for 5 hours.

Embodiment 3

[0033] Measure 40mL ethanol, add 3.8mL acetylacetone (CH 3 COCH 2 COCH 3 ) And stirring, adding 10 mL of n-butyl titanate and continuing to stir to obtain liquid A. Measure 350 mL of deionized water, add 7.218 g of aluminum nitrate and add 3 drops of concentrated nitric acid (65%) dropwise, and stir well to obtain liquid B. Add liquid B to liquid A slowly, and continue to stir to obtain a sol. Weigh 10 g of lithium cobaltate, add 20 mL of deionized water, and stir; measure 2.9 mL of sol and add it dropwise to the lithium cobaltate. After stirring for 2 hours, perform suction filtration, and then put the material in an oven for drying. Put the dried materials into the muffle furnace and calcine at 650℃ for 5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap