Composite Fe3O4 type structured catalyst used for hydrogen production from methane, and preparation method thereof

A structured catalyst and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of slowing down the development of coal gasification hydrogen production process and production cost High hydrogen production cost and other problems, to achieve the effect of improving catalytic efficiency and selectivity, improving life, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

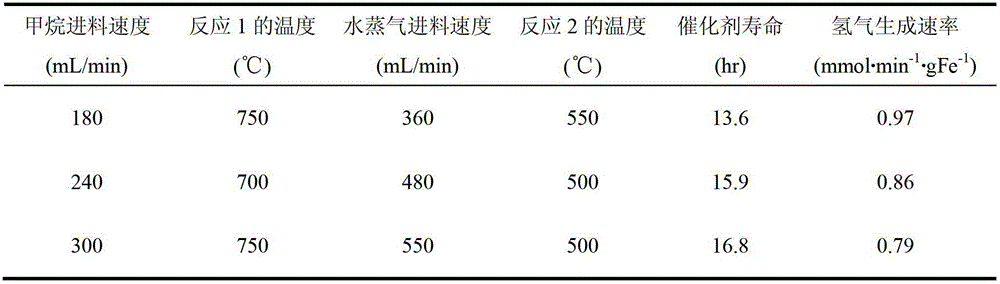

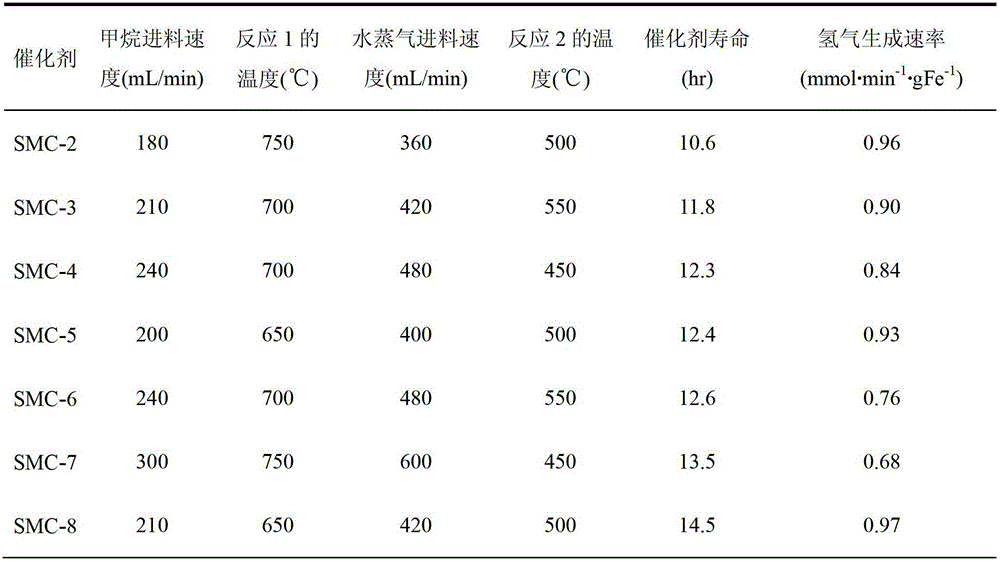

Examples

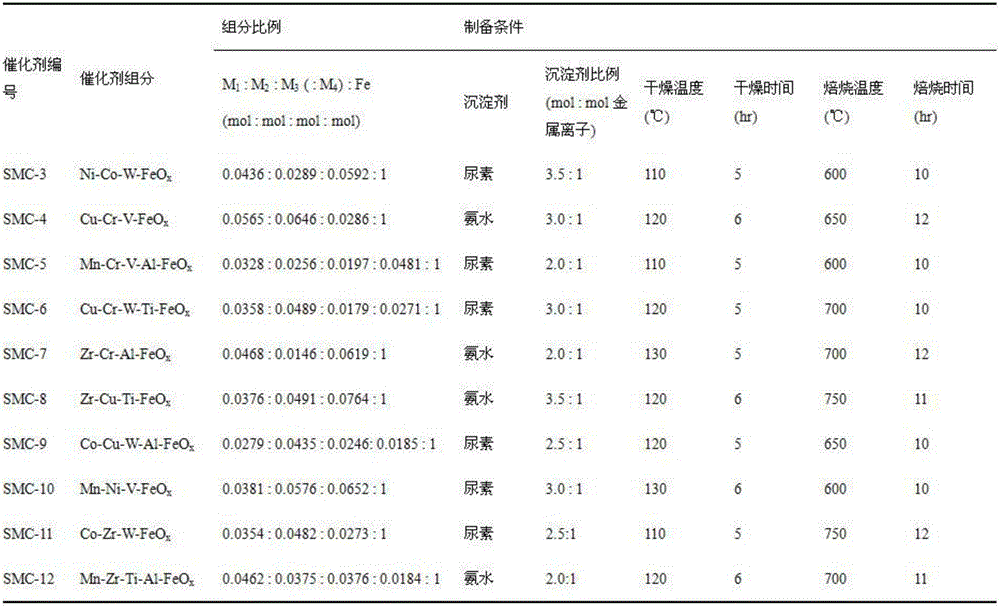

preparation example Construction

[0033] The above composite Fe for hydrogen production from methane 3 o 4 The preparation method of type structured catalyst comprises the following steps:

[0034] The first step: pretreatment cordierite honeycomb ceramic carrier: take the cordierite honeycomb ceramic carrier that is cut into a cylinder with a length of 5-6 cm, and the cordierite honeycomb ceramic carrier has 60-62 holes per square centimeter and a weight of 10 -13g; After smoothing the outer surface of the cordierite honeycomb ceramic carrier with sandpaper, soak the cordierite honeycomb ceramic carrier in glacial acetic acid for 1 to 2 hours, then rinse with distilled water, and then place the cordierite honeycomb ceramic carrier at a temperature of 110-120 ℃ drying oven for 1-1.5 hours, then placed in a muffle furnace for 500-900 ℃ calcination for 2-3 hours, and finally cooled naturally in the air to obtain a pretreated cordierite honeycomb ceramic carrier.

[0035] The second step: prepare the auxiliary ...

Embodiment 1

[0052] The catalyst contains four elements of Zr, Mn, W and Fe, wherein the molar ratio of the four elements is Zr:Mn:W:Fe=0.0385:0.0519:0.0364:1.00. Weigh 10.29 grams (0.0385 moles) of ZrO(NO) 2 2H 2 O, 13.03 grams (0.0519 moles) Mn(NO 3 ) 2 4H 2 O, 13.61 grams (0.0364 moles) (NH 4 ) 2 WO 4 ·5H 2 O and 404.00 g (1.00 mol) Fe(NO 3 ) 3 9H 2 O, add to a 1000mL volumetric flask, add distilled water, and make a solution of about 1.1268mol / L. Pour the solution into a 2000 mL three-neck flask, add 203.03 g (3.3804 moles) of urea, and fully react in a water bath at 90° C. for 5 hours under vigorous stirring to obtain mixed precipitates. The precipitate was filtered and washed with water until neutral, and then the filter cake was washed with absolute ethanol to replace the water in the filter cake. The filter cake was dried at 120°C for 7 hours to constant weight, then roasted at 750°C for 10 hours in a muffle furnace, and cooled to room temperature naturally in the air t...

Embodiment 2

[0058] The catalyst contains four elements of Zr, Ni, V and Fe, wherein the molar ratio of the four elements is Zr:Ni:V:Fe=0.0864:0.0483:0.0272:1.00. Weigh 23.09 grams (0.0864 moles) of ZrO(NO) 2 2H 2 O, 14.05 g (0.0483 mol) Ni(NO 3 ) 2 ·6H 2 O, 3.18 g (0.0272 mol) NH 4 VO 3 , 404.00 g (1.00 mol) Fe(NO 3 ) 3 9H 2 O was added to a 1000mL volumetric flask, and distilled water was added to form a solution of about 1.1619mol / L. The solution was poured into a 2000 mL three-necked flask, and 174.46 g (2.905 moles) of urea was added. Under vigorous stirring, the mixture was fully reacted in a water bath at 80° C. for 4 hours to obtain mixed precipitates. The precipitate was filtered and washed with water until neutral, and then the filter cake was washed with absolute ethanol to replace the water in the filter cake. The filter cake was dried at 120° C. for 6 hours to constant weight, then roasted at 750° C. for 10 hours in a muffle furnace, and cooled naturally to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com