Method for preparing high-purity cornflower pigment

A technology of cornflower pigment and high purity is applied in the field of preparation of high-purity cornflower pigment to achieve the effects of low cost, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

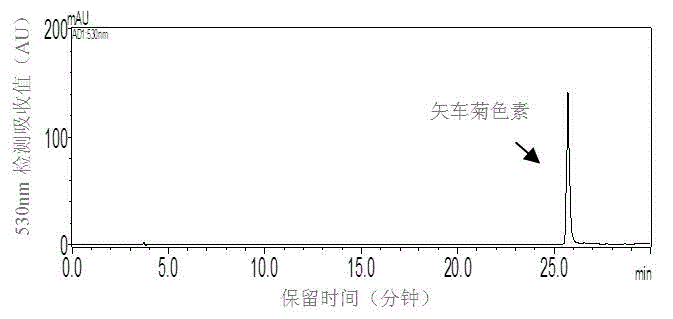

[0027] Main equipment: 1. High performance liquid chromatography (HPLC); 2. Constant temperature water bath; 3. Rotary evaporator; 4. Centrifuge; 5. Crushing machine; 6. AB-8 macroporous resin column; 7. Nitrogen Blow instrument.

[0028] Materials and Reagents:

[0029] 1. Tested material: tea tree root (stored at -80°C for later use);

[0030] 2. Main reagents:

[0031] Acetone (analytical pure), acetic acid (analytical pure), methanol (analytical pure), n-butanol (analytical pure), ethyl acetate (analytical pure), concentrated hydrochloric acid (analytical pure).

[0032] Extract solution: Take 70 ml of acetone, add 29.5 ml of water and 0.5 ml of acetic acid and shake well.

[0033] Pyrolysis solution: Take 95 ml of n-butanol and add 5 ml of concentrated hydrochloric acid.

[0034] 20% methanol: add 20ml methanol to 80ml water and shake well.

[0035] The specific operation steps for preparing high-purity cyanidin are as follows:

[0036] 1) Extraction of proanthocyan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com