Insecticide and fungicide combined agent for treating rice seeds

A technology for seed treatment and composition, applied in the field of pesticides, can solve the problems of decreased sensitivity to prochloraz, decreased control effect of rice bakanae disease, etc., and achieves the effects of reducing adverse effects, saving drug cost and labor cost, and expanding control objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

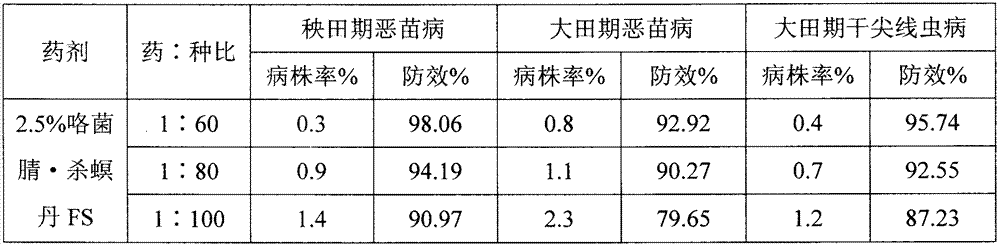

[0018] Embodiment 1: 2.5% rhypronil·cartap suspension seed coating

[0019] Weigh 0.5 g of the original drug of fludioxonil and 2 g of the original drug of cartap, add the two original drugs into water, stir in a stirring tank to a homogeneous liquid, add 0.5% to 10% of a dispersant (sodium lignosulfonate), and moisten Agent (alkyl naphthalene sulfonate) 0.5% ~ 10%, film forming agent (polyvinyl acetate) 4%, after stirring evenly; under 60 ~ 120rpm / min mechanical stirring, slowly add the thickener ( Polyvinyl alcohol) 0.1%~5%, warning color (basic rhodamine) 1%, antifreeze agent (ethylene glycol) 0.1%~5%, defoamer (silicone oil) 0.01%~3%, make up to 100ml with water, When grinding, the air compressed pipeline is used to transport the material liquid, and 4 sets of sand mills connected in series (filled with fine zirconia beads and coarse zirconia beads) are used for continuous sand grinding to make 2.5% fludioxonil·cartap suspension seed coat agent (FS).

Embodiment 2

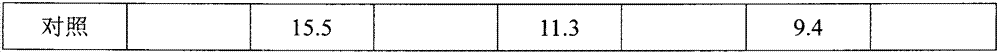

[0020] Embodiment 2: 5% fludioxonil · cartap microemulsion

[0021] Weigh 2.5g of fludioxonil and 2.5g of cartap, add 5% to 25% of organic solvent, 5% to 25% of emulsifier, 0.1% to 5% of antifreeze, make up to 100ml with water, and make 5 % Fludioxonil Cartap ME;

[0022] In the above-mentioned microemulsion trial production, the organic solvent is 150# mineral spirits, the emulsifier is fatty acid polyoxyethylene ether series mixture, and the antifreeze agent is ethylene glycol. Fludioxonil is added into the organic solvent under the condition of stirring, then a co-solvent is added, and after the original drug is completely dissolved, an emulsifier is added and the emulsifier is dissolved. Add water and antifreeze under the condition of 50-90rpm / min, add cartap original drug, and stir for 30 minutes to obtain a uniform and transparent microemulsion.

Embodiment 3

[0023] Embodiment 3: 15% fludioxonil · cartap suspension concentrate

[0024] Weigh 5 g of fludioxonil technical material and 10 g of cartap technical drug, add the two technical medicines into water, stir in a stirring tank to a homogeneous liquid, add dispersant (sodium lignosulfonate) 0.5% to 10%, wetting agent (Alkyl naphthalene sulfonate) 0.5% ~ 10%, after stirring evenly; under mechanical stirring at 60 ~ 120rpm / min, slowly add thickener (polyvinyl alcohol) 0.1% ~ 5% diluted with water, antifreeze ( Ethylene glycol) 0.1% to 5%, defoamer (silicone oil) 0.01% to 3%, make up to 100ml with water, use air compression pipeline to transport material liquid during grinding, and use 4 sand mills in series (fill fine oxidation Zirconium beads and coarse zirconia beads) are continuously sanded to make 15% fludioxonil · cartap SC;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com