Method for producing liquid water-soluble carbon fertilizer with high-concentration organic waste water

An organic wastewater, high-concentration technology, applied in the direction of organic fertilizer, sewage/sludge fertilizer, application, etc., to achieve strong diffusion and permeability, promote crop growth and soil microbial reproduction, strong crop growth and soil microbial reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] High-concentration alcohol wastewater is used to produce liquid water-soluble carbon fertilizer. The specific gravity of the liquid water-soluble carbon fertilizer product is 1.20-1.25. It is light brown clear liquid without sediment, and its carbon content is 131-171g / L.

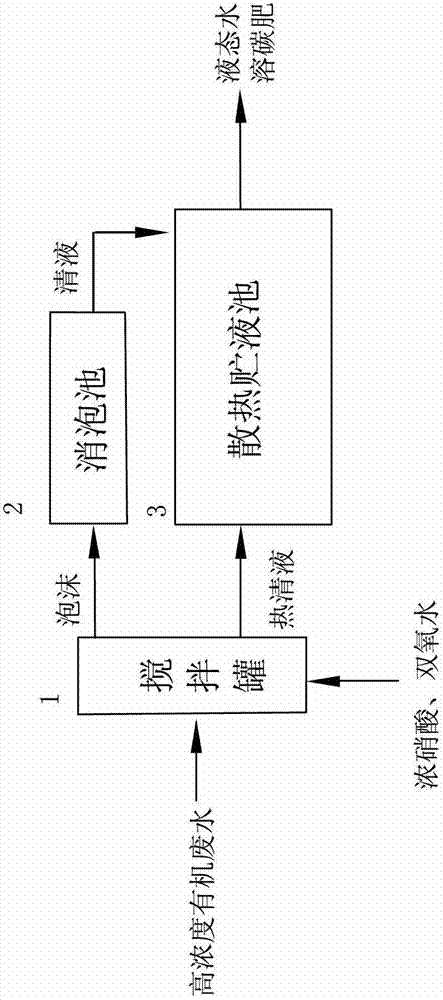

[0066] For its production process, please refer to figure 1 : 2KG purity 95% concentrated nitric acid (HNO 3 ) and 4KG of 83% pure hydrogen peroxide (H 2 o 2 ) and start the stirring paddle in the stirring tank, the rotating speed of the stirring paddle is 120 rpm, and stirring for 60 minutes, the organic macromolecules in the wastewater are rapidly cracked into small molecular groups by strong oxidation during stirring; during the stirring process, the stirring tank 1 The foam generated by the internal liquid material is diverted to the defoaming pool 2 for natural defoaming, and after becoming a clear liquid, it is discharged into the heat dissipation liquid storage pool 3; most of the liquid ma...

Embodiment 2

[0080] Use high-concentration monosodium glutamate wastewater to produce liquid water-soluble carbon fertilizer. The specific gravity of the liquid water-soluble carbon fertilizer product is 1.20-1.25, which is light brown clear liquid without sediment, and its carbon content is 131-171g / L.

[0081] For its production process, please refer to figure 1 : Enter 2KG of concentrated nitric acid with a purity of 95% and 4KG of hydrogen peroxide with a purity of 83% at the bottom of the mixing tank 1 equipped with 100KG of high-concentration monosodium glutamate waste water with a water content of 60% and an organic matter content of 20% of the total weight and start the mixing tank. Stirring paddle, the rotating speed of the stirring paddle is 180 rpm, stirring for 45 minutes, the organic macromolecular groups in the waste water are subjected to strong oxidation during stirring and are quickly cracked into small molecular groups; the foam generated by the liquid material in the sti...

Embodiment 3

[0095]High-concentration yeast wastewater is used to produce liquid water-soluble carbon fertilizer. The liquid water-soluble carbon fertilizer product has a specific gravity of 1.20-1.25, a light brown clear liquid, no sediment, and a carbon content of 131-171g / L.

[0096] For its production process, please refer to figure 1 : Enter 2KG of concentrated nitric acid with a purity of 95% and 4KG of hydrogen peroxide with a purity of 83% at the bottom of the mixing tank 1 equipped with 100KG of high-concentration yeast wastewater with a water content of 55% and an organic matter content of 22.5% of the total weight, and start the mixing process in the mixing tank Stirring paddle, the rotating speed of the stirring paddle is 150 rpm, stirring for 50 minutes, the organic macromolecular groups in the waste water are subjected to strong oxidation during stirring and are quickly cracked into small molecular groups; the foam generated by the liquid material in the stirring tank 1 durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com