Method for separating component from direct-coal-liquefaction full distillate oil by utilizing solid-phase extraction method

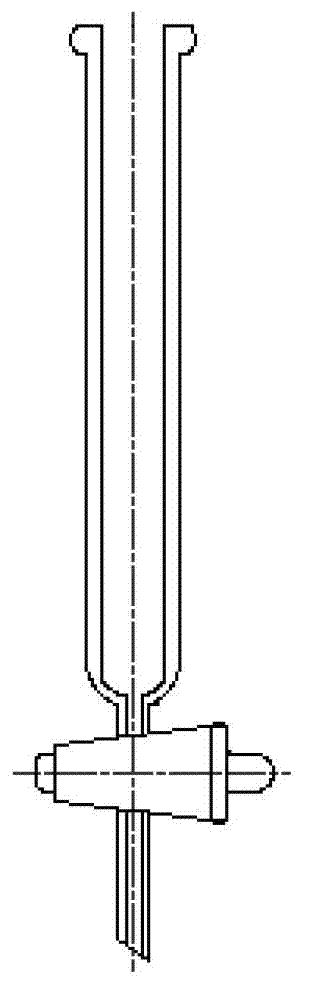

A technology of direct liquefaction of coal and solid phase extraction method, applied in the field of coal chemical industry, can solve the problems of long separation time and poor effect, and achieve the effect of good elution effect, prolonging contact time and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

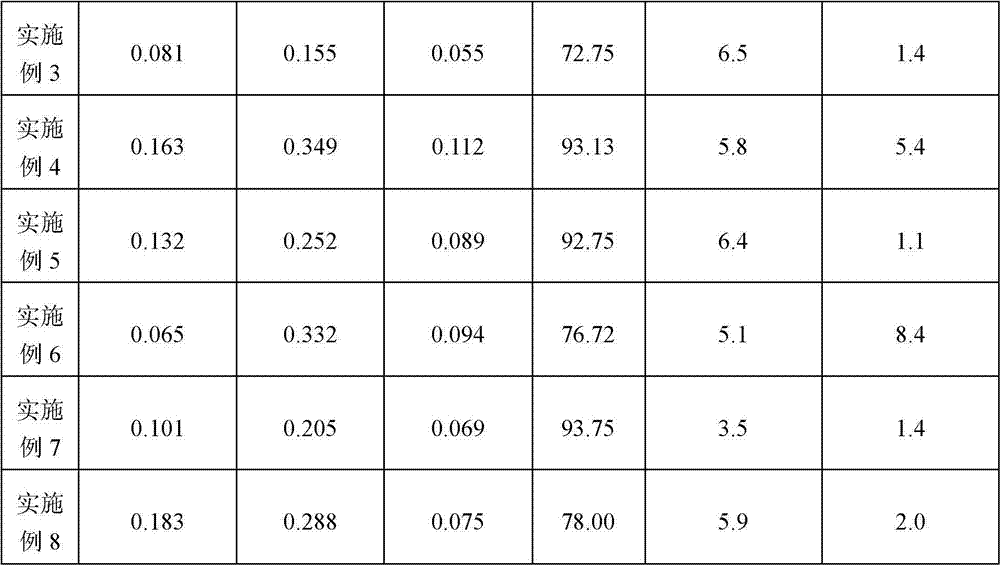

[0039] Take 1.01 g of the sample to be separated as the sample to be separated in Example 1, and place it in the CQ1 column. First wet the stationary phase with 30ml of n-hexane, then wash the sample to be separated attached to the stationary phase with 40ml of n-hexane, control the washing rate of n-hexane solution to 30ml / min, and obtain a saturated hydrocarbon solution; after extracting the saturated hydrocarbons, use 50ml Rinse the extraction column with dichloromethane at a controlled washing rate of 35ml / min to obtain an aromatic hydrocarbon solution; finally rinse the colloid with 40ml of absolute ethanol at a controlled rinsing rate of 30ml / min to obtain a colloidal solution. The n-hexane in the saturated hydrocarbon solution, the dichloromethane in the aromatic hydrocarbon solution, and the absolute ethanol in the colloidal solution were respectively distilled off in a water bath at 90°C to obtain the contents of each component as described in Table 1.

Embodiment 2

[0041] Take 0.53g of the sample to be separated as the sample to be separated in Example 2, and place it in the CQ1 column. Wet the stationary phase with 30ml of n-hexane first, then rinse the sample to be separated attached to the stationary phase with 20ml of n-hexane, control the washing rate of the n-hexane solution to 20ml / min, and obtain a saturated hydrocarbon solution; after extracting the saturated hydrocarbons, use 30ml Rinse the extraction column with dichloromethane, and control the washing rate to 20ml / min to obtain an aromatic hydrocarbon solution; finally wash the colloid with 30ml of absolute ethanol, and control the rinsing rate to 10ml / min to obtain a colloid solution. The n-hexane in the saturated hydrocarbon solution, the dichloromethane in the aromatic hydrocarbon solution, and the absolute ethanol in the colloidal solution were respectively distilled off in a water bath at 90°C to obtain the contents of each component as described in Table 1.

Embodiment 3

[0043] Get 0.40g of the sample to be separated as the sample to be separated in Example 3, and place it in the CQ2 column. Wet the stationary phase with 30ml or 20ml of n-hexane first, then wash the sample to be separated attached to the stationary phase with 20ml of n-hexane, control the washing rate of the n-hexane solution to 30ml / min, and obtain a saturated hydrocarbon solution; after extracting the saturated hydrocarbon, use 20ml Rinse the extraction column with dichloromethane at a controlled washing rate of 20ml / min to obtain an aromatic hydrocarbon solution; finally rinse the colloid with 30ml of absolute ethanol at a controlled rinsing rate of 50ml / min to obtain a colloidal solution. The n-hexane in the saturated hydrocarbon solution, the dichloromethane in the aromatic hydrocarbon solution, and the absolute ethanol in the colloidal solution were respectively distilled off in a water bath at 90°C to obtain the contents of each component as described in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com