Fermentation process for producing pravastatin by transforming compactin by using actinomadura yumaense

A technology of actinomycetes madura and fermentation process, applied in the directions of fermentation, microorganism-based methods, microorganisms, etc., to achieve the effect of being beneficial to the proliferation of bacteria, shortening the lag period, and improving the level of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

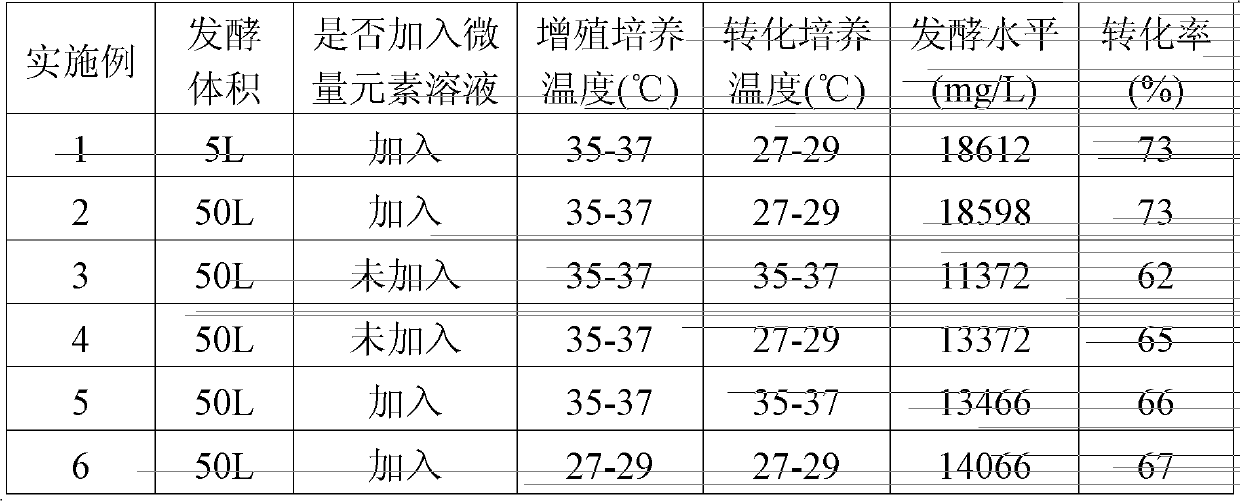

Examples

Embodiment 1

[0052] A kind of fermenting process of using actinomycetes madura to transform compatin to produce pravastatin of the present embodiment, the concrete steps of this fermenting process are as follows:

[0053] The trace element solution of the present embodiment is prepared according to the following formula:

[0054] Sodium molybdate (Na 2 MoO 4 2H 2 O) 0.1g / L;

[0055] Boric acid (H 3 BO 3 ) 1.0g / L;

[0056] Manganese chloride (MnCl 2 ·H 2 O) 0.1g / L;

[0057] Zinc sulfate (ZnSO 4 ·7H 2 O) 5.0g / L;

[0058] Ferrous Sulfate (FeSO 4 ·7H 2 O) 1.5g / L;

[0059] Sodium nitrate (NaNO 3 ) 3.0g / L;

[0060] Citric acid (C 6 h 8 o 7 ) 1.5g / L;

[0061] Copper Sulfate (CuSO 4 ·5H 2 O) 0.2g / L.

[0062] Step 1 Seed Culture

[0063] First prepare 350mL seed medium in a 1L shake flask according to the following formula:

[0064] Glucose 30g / L, yeast extract 20g / L, soybean peptone 5g / L, K 2 HPO 4 ·3H 2 O2g / L, MgSO 4 ·7H 2 O 0.5g / L and antifoaming agent 1.0g / L.

[0...

Embodiment 2

[0072] In this embodiment, a 50L fully automatic fermenter is used to transform conbatin into pravastatin with actinomycetes madura, and the specific steps of the fermentation process are as follows:

[0073] The trace element solution of the present embodiment is prepared according to the following formula:

[0074] Sodium molybdate (Na 2 MoO 4 2H 2 O) 0.2g / L;

[0075] Boric acid (H 3 BO 3 ) 1.5g / L;

[0076] Manganese chloride (MnCl 2 ·H 2 O) 0.2g / L;

[0077] Zinc sulfate (ZnSO 4 ·7H 2 O) 5.5g / L;

[0078] Ferrous Sulfate (FeSO 4 ·7H 2 O) 2.0g / L;

[0079] Sodium nitrate (NaNO 3 ) 3.3g / L;

[0080] Citric acid (C 6 h 8 o 7 ) 2.0g / L;

[0081] Copper Sulfate (CuSO 4 ·5H 2 O) 0.3g / L.

[0082] Seed culture method is the same as embodiment 1.

[0083] The fermentation culture operation is as follows:

[0084] First prepare 30L fermentation medium according to the following formula: glucose 60g / L, yeast extract 25g / L, soybean peptone 5g / L, K 2 HPO 4 ·3H 2 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com