A leak-proof bipolar current collector and high-voltage battery and its preparation method

A bipolar and current collector technology, applied in the direction of electrode carrier/current collector, can solve the problems of poor conductivity, current collector leakage, battery short circuit, etc., and achieve the effects of easy preparation, prevention of internal short circuit, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

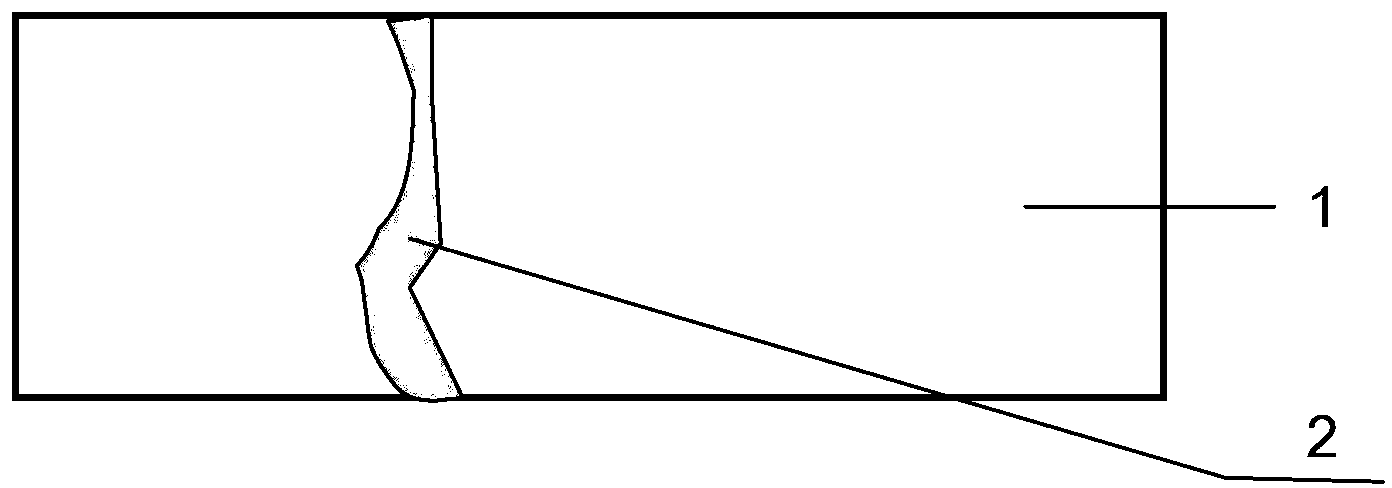

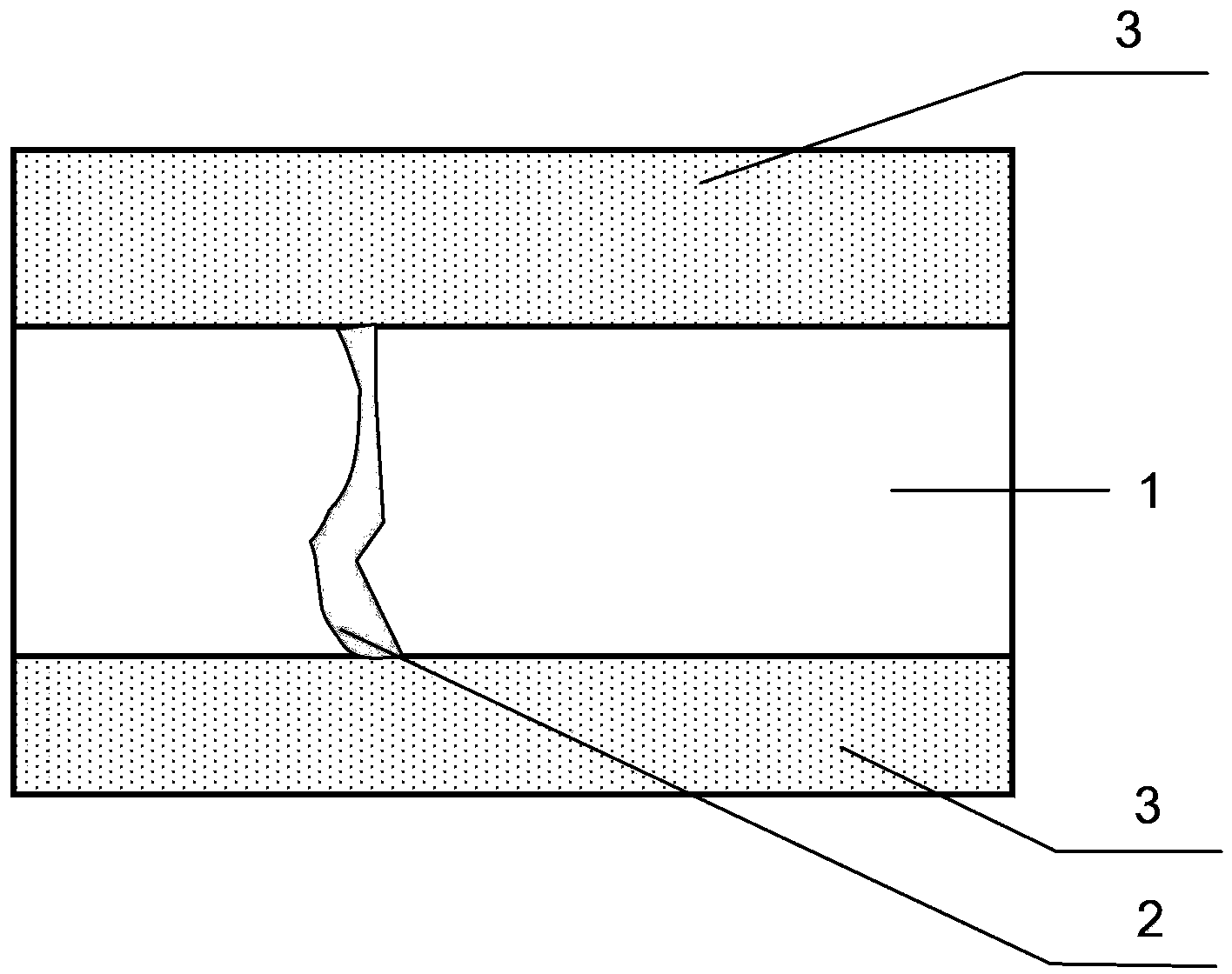

[0047] In this embodiment, the anti-leakage bipolar current collector includes: the metal film 1 is nickel-plated on one side of aluminum; the polymer 2 is polyvinylidene fluoride and polyethylene; and the conductive powder is carbon black. Among them, the thickness of the metal film is 20 μm, the penetrating cracks and holes of the metal film are filled with polyvinylidene fluoride and polyethylene, the thickness of the film layer 3 is 2 μm, the (polyvinylidene fluoride + polyethylene) in the film layer : Carbon black (mass ratio) is (5+25):80.

[0048] The preparation method of the anti-leakage bipolar current collector of this embodiment is as follows:

[0049] 1) Pretreatment of the metal film:

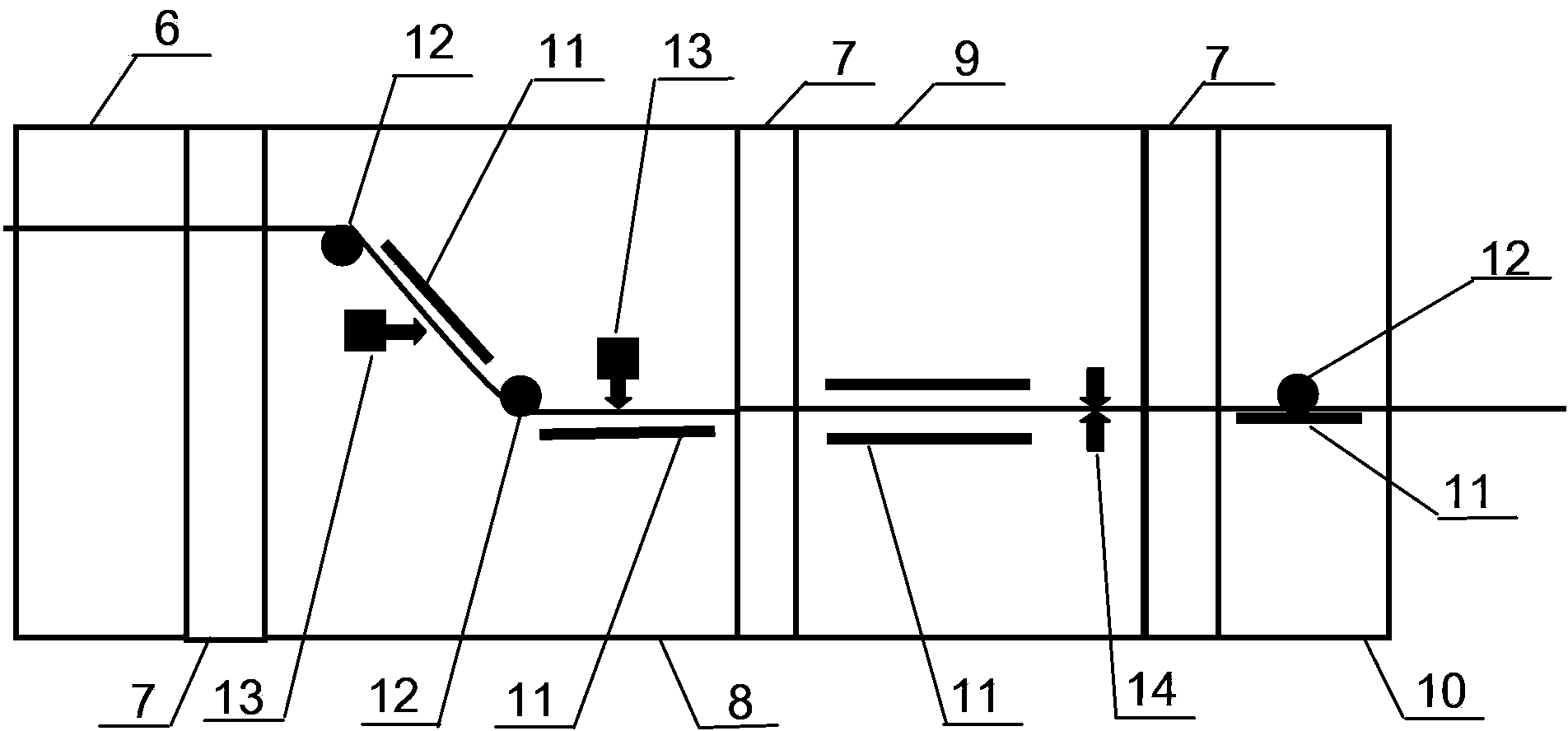

[0050] a. Spray and clean the metal film, that is, the metal film enters the metal film pretreatment chamber 6, sprays and cleans it with acetone, controls the room temperature at 50° C., and cleans for 6 minutes to remove oil stains;

[0051] b. Dry the metal film at a temperat...

Embodiment 2

[0057] In this embodiment, polyvinylidene fluoride and maleic anhydride grafted polyethylene are used as the polymer 2, and the others are the same as in the first embodiment.

[0058] In the preparation method of the anti-leakage bipolar current collector of this embodiment, in step 2), the PE powder is replaced by MAH-g-PE powder, and the other is the same as the first embodiment.

Embodiment 3

[0060] In this embodiment, the anti-leakage bipolar current collector includes: the metal film 1 is copper-plated on one side of aluminum; the polymer 2 is polyvinylidene fluoride and polypropylene; and the conductive powder is carbon black. Among them, the thickness of the metal film is 20 μm, the penetrating cracks and holes of the metal film are filled with polyvinylidene fluoride and polypropylene, the thickness of the film layer 3 is 4 μm, (polyvinylidene fluoride + polypropylene): carbon black (mass ratio ) is (5+25):70.

[0061] The preparation method of the anti-leakage bipolar current collector of this embodiment is as follows:

[0062] 1) Same as step 1) of Embodiment 1;

[0063] 2) Vacuum casting coating of the metal film: pull the metal film to the vacuum casting coating chamber 8, vacuumize, the vacuum degree is 10Pa, the temperature of the heating plate 11 and the heating roller 12 is 280°C, dry the metal film, and make it Keep the metal film at this temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com