Chickpea natto and making method and application of chickpea natto

A technology for chickpeas and natto, which is applied in the field of chickpeas and natto and its preparation, can solve the problems that the protective effect of nattokinase is rarely reported and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

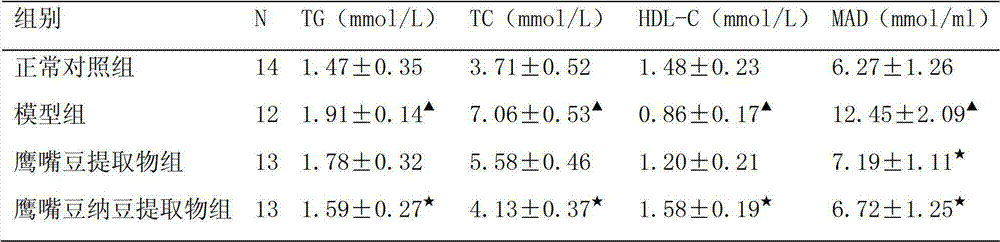

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 100g of chickpeas (purchased from Xinjiang Dalongwang Food Co., Ltd.) into 400mL of 30°C hot water and soak for 60min, drain and then soak in 400mL of 0.6% KCl solution by mass percentage for 1h, wash and drain, and then transfer to a tile pan. The spacing is 2mm, covered with wet cloth (4 layers of gauze), and the humidity is kept at 100%. Cultivate in a constant temperature and humidity incubator at 40°C until the germination reaches 5mm; add 1g glucose, 0.2gNaCl, 40mL water to the germinated chickpeas, 2g buckwheat flour, stir well, cook at 121°C for 1h, inoculate with 2mL Natto Bacillus subtilis liquid (purchased from Takahashi Yuzo Research Institute, Japan) after cooling, and culture at 37.5°C for 36h; fermented chickpea natto Place it in a refrigerator at 4°C overnight (10h), then move it into a drying tray, add 0.2g cyclodextrin as a cryoprotectant before drying, pre-freeze at -15°C, freeze-dry for 18h, and decompose at 20°C; The dried product was pulverized...

Embodiment 2

[0022] Add 100g of chickpeas (purchased from Xinjiang Dalongwang Food Co., Ltd.) into 400mL of 60°C hot water for 10min, and then add 400mL of 0.8% NaHCO 3 Soak in the solution for 4 hours; wash and drain, then move into tile trays, the distance between beans is 6mm, cover with wet cloth (2 layers of terry cloth), keep the humidity at 50%, cultivate in a constant temperature and humidity incubator at 10°C, and wait for germination to 1mm; Add 5.0g glucose, 1.0gNaCl, 100mL water, 5g buckwheat flour to the chickpeas, stir evenly, cook at 110°C for 2h, cool and use 6.0mL Natto Bacillus subtilis liquid (purchased from Takahashi Yuzo Research Institute, Japan) Inoculate and culture at 37.5°C for 24h; after fermentation, chickpea and natto should be placed in a refrigerator at 0°C overnight (18h), then transferred to a drying tray, and 1.2g of cyclodextrin was added as a cryoprotectant before drying, and the pre-freezing temperature was - 25°C, freeze-dried for 36 hours, and the ana...

Embodiment 3

[0024] Add 100g of chickpeas (purchased from Xinjiang Dalongwang Food Co., Ltd.) into 400mL of 40°C hot water and soak for 40min, then drain with 400mL of 0.1% NaHCO 3 , 0.1% KCl solution soaked for 2 hours, cleaned and drained, then moved into tile trays, the spacing between beans was 3mm, covered with wet cloth (4 layers of gauze) on top, and kept at a humidity of 70%, cultivated in a constant temperature and humidity incubator at 37°C, and germinated to 3mm Grind the germinated chickpeas, add 3g of glucose, 0.9gNaCl, 80mL of water, 4g of buckwheat flour, stir well and cook at 115°C for 90min, after cooling, use 3.0mL of Natto Bacillus subtilis liquid (purchased from Takahashi, Japan Yuzang Research Institute) inoculated and cultured at 37.5°C for 32h; fermented chickpea and natto were placed in a refrigerator at 2°C overnight (12h), then moved into a drying tray, and 1.0g of cyclodextrin was added as a cryoprotectant before drying. The pre-freezing temperature is -20°C, fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com