Elastic shape memory recyclable bracket and manufacturing method and using method thereof

An elastic and memory technology, applied in the field of medical devices, can solve problems such as recyclable stents that have not yet been seen, and achieve the effects of reducing medical burden, simple manufacturing process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

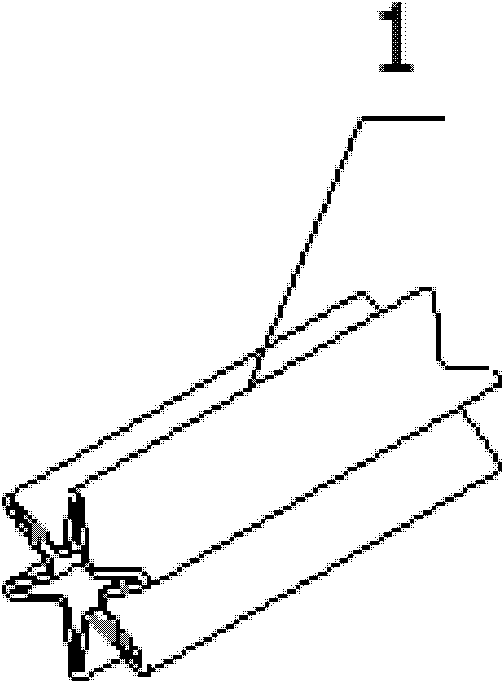

[0038] Process a star-shaped mold, put polyurethane particles with a glass transition temperature (i.e. shape memory recovery temperature) of 39°C into the mold, pressurize it at a temperature higher than its melting point, and make a star-shaped bracket after demolding 1 ,like figure 1 shown.

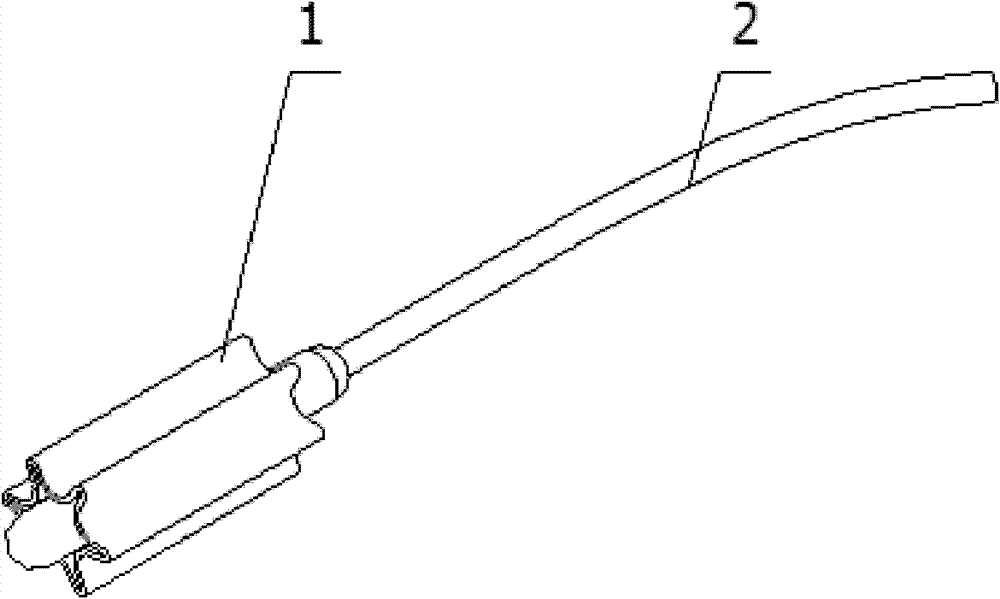

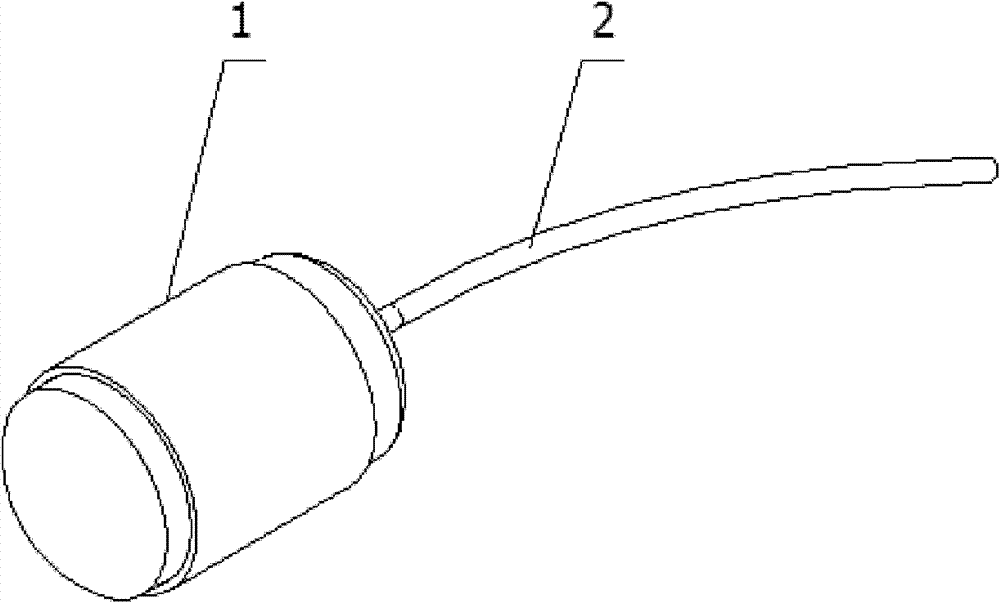

[0039] At a temperature 15°C higher than its glass transition temperature, the star-shaped stent 1 is expanded into a tubular stent 1 by expanding the balloon 2, such as figure 2 and image 3 shown. and then cooled to room temperature, the scaffold will remain tubular, as Figure 4 shown.

[0040] After the tubular stent is sterilized, it is vacuum-dried and sealed for future use.

[0041] During use, the tubular stent is compressed into a catheter by utilizing the elasticity of polyurethane, and delivered to the diseased part 3 in the body. When the catheter is removed, the stent 1 will expand in the form of a tube at the diseased part through the recovery of elastic deformation...

Embodiment 2

[0044] Process a star mold.

[0045] Magnetic Fe 3 o 4 The micropowder was uniformly mixed into the polyurethane solution with a glass transition temperature (i.e. shape memory recovery temperature) of 39°C by ultrasonic oscillation, Fe 3 o 4 The weight percentage of fine powder and polyurethane is 5:95.

[0046] Pour the above mixed liquid into the mold, heat it to 80°C to make it solidify and form, and after demolding, the Fe-containing 3 o 4 Micronized star holder.

[0047] At a temperature 15°C higher than the glass transition temperature of polyurethane, the Fe-containing 3 o 4 The micropowdered star-shaped scaffold expanded into a tubular shape, and then cooled to room temperature, the scaffold will remain tubular.

[0048] will contain Fe 3 o 4 After the micropowdered tubular stent is sterilized, it is vacuum-dried and sealed for future use.

[0049] In use, the elasticity of polyurethane will contain Fe 3 o 4The micropowdered tubular stent is compressed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com