Post-treatment method of fluorescent powder for lamp

A fluorescent powder and ammonium fluoride technology, applied in the field of light sources, can solve the problems of loose and non-dense film, poor transparency of fluorescent powder, and affecting the external quantum efficiency of white light LED devices, so as to improve the light extraction rate, improve the external quantum efficiency, Consumption saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

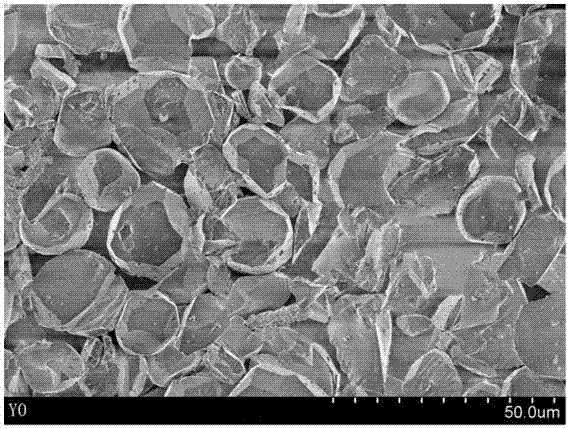

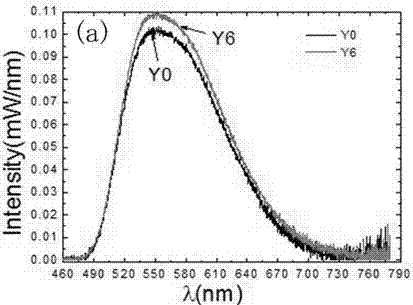

[0026] The phosphor used in this embodiment is a phosphor for white LEDs, and its composition is Y 3 Al 5 O 12 :Ce 3+ , which were prepared by a high-temperature solid-phase method. The mixed solution of the present embodiment adopts ammonium fluoride and nitric acid to mix, and the specific implementation steps are as follows:

[0027] Step 1: Put 10mg of YAG phosphor into a plastic bottle, then pour 50mL of 40% mass concentration of ammonium fluoride and nitric acid mixture into the bottle, and shake well.

[0028] Step 2: Put the plastic bottle in an ultrasonic water bath and set the water temperature to keep at 90 degrees Celsius.

[0029] Step 3: After 6 hours, take out the plastic bottle, pour out the acid solution after the phosphor is precipitated, and leave the treated phosphor, then pour it into deionized water and then put it into an ultrasonic water bath for cleaning, after about 5 minutes, put the Take out the ultrasonic water bath from the plastic bottle, an...

Embodiment 2

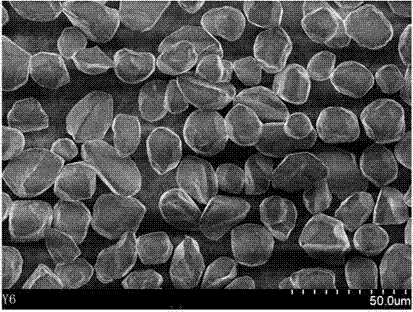

[0033] The phosphor used in this embodiment is a phosphor for white LEDs, and its composition is Y 3 Al 5 O 12 :Ce 3+ , which were prepared by a high-temperature solid-phase method. The mixed solution of the present embodiment adopts ammonium fluoride and phosphoric acid to mix, and the specific implementation steps are as follows:

[0034] Step 1: Put 10mg YAG phosphor into a plastic bottle, then pour 50mL of 50% mass concentration of ammonium fluoride and phosphoric acid mixture into the bottle, and shake well.

[0035] Step 2: Put the plastic bottle in an ultrasonic water bath and set the water temperature to keep at 80 degrees Celsius.

[0036] Step 3: After 5 hours, take out the plastic bottle, pour out the acid solution after the phosphor is precipitated, and leave the treated phosphor, then pour it into deionized water and then put it into an ultrasonic water bath for cleaning, after about 5 minutes Take out the ultrasonic water bath from the plastic bottle, and po...

Embodiment 3

[0040]The phosphor powder used in this embodiment is the phosphor powder for white light LED, and its composition is Y 3 Al 5 o 12 : Ce 3+ , was prepared by a high-temperature solid-phase method. The mixed solution of the present embodiment adopts ammonium fluoride and glacial acetic acid to mix, and concrete implementation steps are as follows:

[0041] Step 1: Put 10mg of YAG phosphor into a plastic bottle, then pour 50mL of a mixture of 70% mass concentration ammonium fluoride and glacial acetic acid into the bottle, and shake well.

[0042] Step 2: Put the plastic bottle into an ultrasonic water bath, and set the water temperature at 80 degrees Celsius.

[0043] Step 3: After 5 hours, take out the plastic bottle, pour out the acid solution after the phosphor powder is precipitated, and then pour deionized water into the ultrasonic water bath for cleaning. Take the plastic bottle out of the ultrasonic water bath, and pour out the deionized water after the phosphor powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com