Long-life fully synthetic industrial gear lubricant composition

A technology of gear lubricating oil and composition, which is applied in the field of lubricating oil composition and industrial gear transmission system lubricating oil composition, can solve the problems of undisclosed literature reports on the specific composition of additives, and achieve good economic and social benefits, Excellent high and low temperature performance, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

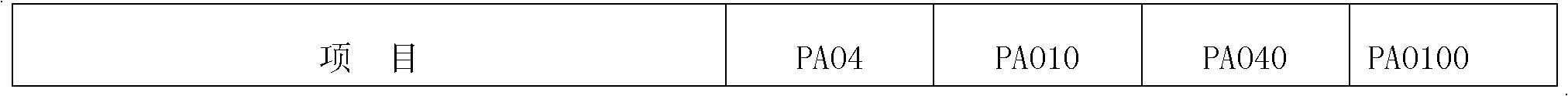

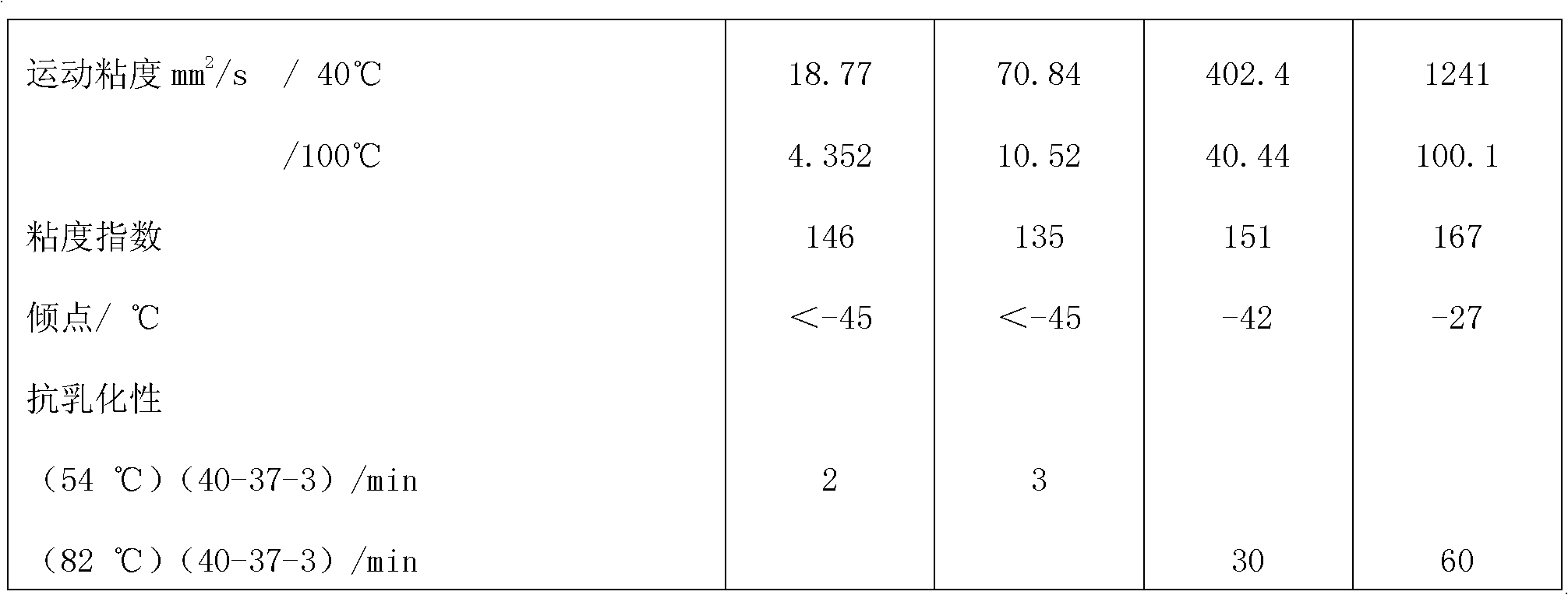

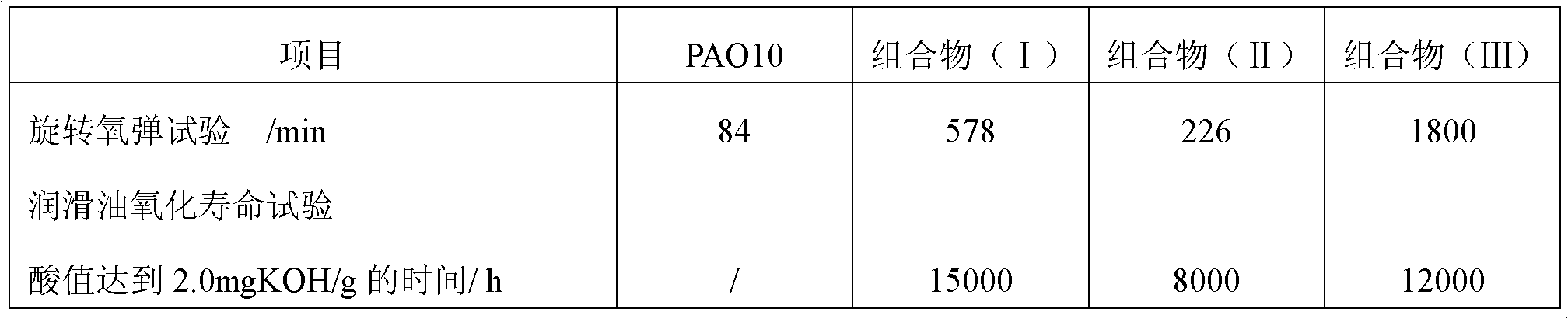

[0023]Lubricating oil composition (I), it comprises: 95.9wt% polyalpha-olefin synthetic base oil PAO-10 (property sees Table 1) (component A); 0.50wt% 2,6-di-tert-butylphenol , 0.50wt% N-phenyl-α-naphthylamine and dinonyldiphenylamine condensate (component B); 0.20wt% benzotriazole di-n-octylamine formaldehyde condensate (component C); 0.2wt% C14-18 alkyl salicylate (component D); 2.0wt% tricresyl phosphate (component E); 0.50wt% oleic acid amide (component F); 0.20wt% octadecene Acid amine salt (component G). The lubricating oil composition (II) except component (B) 0.50wt% N-phenyl-α-naphthylamine and dinonyl diphenylamine condensate is replaced by 0.50wt% di-n-octyl dithiocarbamate Except for replacement, all the other are the same as composition (I). Lubricating oil composition (III) except component (A) 0.50wt% N-phenyl-alpha-naphthylamine and dinonyl diphenylamine condensate is replaced by 0.25wt% N-phenyl-alpha-naphthylamine and dinonyl diphenylamine Except for nonyl...

Embodiment 2

[0031] Lubricating oil composition (IV), it comprises: the polyalpha-olefin synthetic base oil PAO-4 of 13.7wt%, the polyalpha-olefinic synthetic base oil PAO-100 of 77.8wt% (property sees Table 1) (component A ); 1.0wt% of 2,6-di-tert-butylphenol, 1.0wt% of N-phenyl-α-naphthylamine and butylnonyl diphenylamine condensate, 1.0wt% of di-n-butyldithiocarbamic acid Esters (component B); 1.0 wt% thiadiazole dodecyl mercaptan hydroperoxide condensate (component C); 2.0 wt% C8-12 sulfurized alkylphenates (component D); 1.0 wt % tricresyl phosphate (component E); 0.50 wt% monoisooctyl dodecenylsuccinate (component F); 1.0 wt% octadecenoate (component G). Lubricating oil composition (V) is the same as composition (IV) except that 1.0wt% tricresyl phosphate in component (E) is replaced by 1.0wt% lauryl phosphite. Lubricating oil composition (VI) is the same as composition (IV) except that 1.0 wt% tricresyl phosphate in component (E) is replaced by 1.0 wt% dodecylamine phosphate. Lubr...

Embodiment 3

[0036] Lubricating oil composition (IX), it comprises: the polyalpha-olefin synthetic base oil PAO-40 of 88.73wt%, the polyalpha-olefinic synthetic base oil PAO-100 (property see Table 1) of 4.67wt% (component A ); 0.3wt% of 2,6-di-tert-butylphenol, 0.5wt% of N-phenyl-α-naphthylamine and dinonyl diphenylamine condensate, 0.5wt% of di-n-octyl dithioamino Formic acid ester (component B); 0.1 wt% benzotriazole di-n-butylamine formaldehyde condensate (component C); 2.0 wt% C8-12 sulfurized alkylphenate (component D); 0.5 wt% phosphoric acid Tricresyl, 0.5 wt% lauryl phosphite, 0.5 wt% dodecyl phosphate, 0.5 wt% tris(dodecyl)phosphorothioate (component E); 1.0 wt% oil Acid Amide (Component F); 0.2% by weight of Octadenoic Acid Ammonium Salt (Component G). Lubricating oil composition (X) is the same as composition (IX) except that 2.0wt% of C8-12 sulfurized alkylphenate in component (D) is replaced by 2.0wt% of C14-18 alkyl salicylate . Lubricating oil composition (XI) is the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com