Cu-Cu2O-CuO ternary copper-based solid solution catalyst and its preparation method

A cu-cu2o-cuo, ternary copper technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of uneven distribution of active sites, uncontrollable defect concentration, etc., to achieve The reaction conditions are easy to master, easy to produce on a large scale, and avoid the effect of easy particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

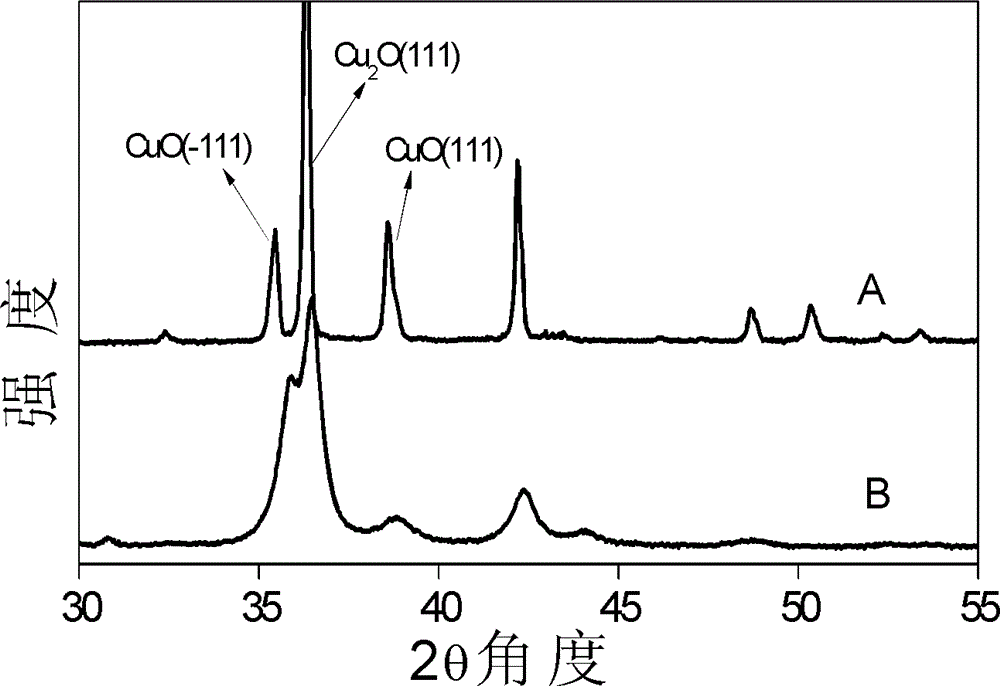

[0028] Weigh 1.22g (12.2wt%) of metal copper powder, 5.66g (56.6wt%) of cuprous oxide, and 3.12g (31.2wt%) of copper oxide as the reaction raw materials, and treat them at 600°C for 8h in a protective atmosphere, and then Aged at 400°C for 8 hours, the product was pulverized and ball milled to obtain a ternary copper-based solid-solution catalyst; the composition of the obtained copper catalyst was analyzed by chemical method: 0.5% Cu, 71.1% Cu 2 O and 28.4% CuO.

[0029] The prepared catalyst material was tested by XRD on X'Pert PRO MPD multifunctional X-ray diffractometer produced by Panalytical Company (Panalytical) in Holland.

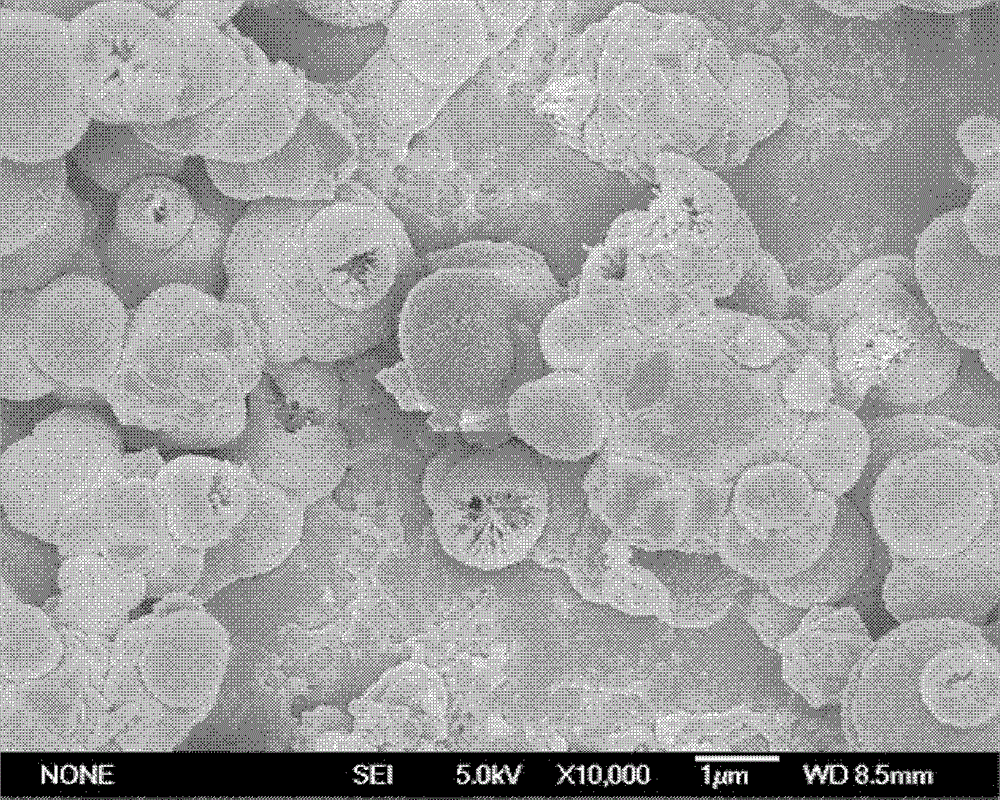

[0030] The surface morphology of the prepared catalyst material was observed with a JSM6700 field emission scanning electron microscope produced by JEOL Ltd.

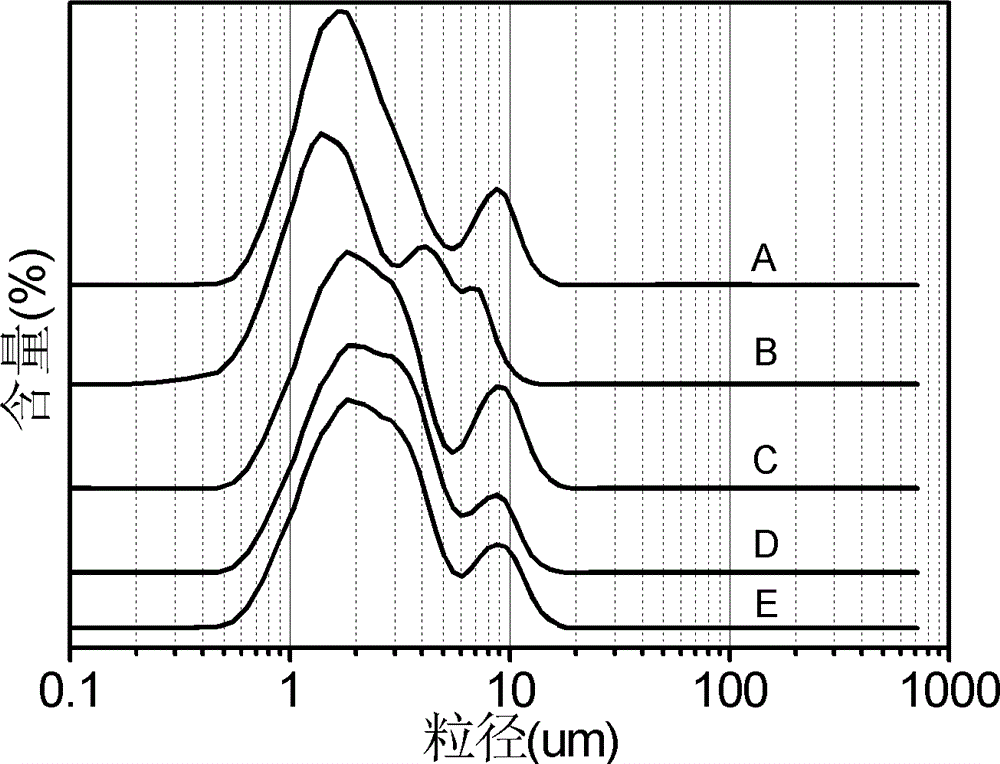

[0031] The particle size analysis of the catalyst material prepared in the above examples was carried out on a Dandong Baite BT-9300Z laser particle size distribution analyzer.

[0032] fig...

Embodiment 2

[0035] Weigh 4.00g (40.0wt%) of metal copper powder, 3.66g (36.6wt%) of cuprous oxide, and 2.34g (23.4wt%) of copper oxide as reaction raw materials, and treat them at 900°C for 0.5h in a protective atmosphere, and then Aging at 400°C for 2 hours, the product was pulverized and ball milled to obtain a ternary copper-based solid-solution catalyst; the composition of the obtained copper catalyst was analyzed by chemical method: 18.1% Cu, 70.9% Cu 2 O and 11.0% CuO. The particle diameters of the ternary copper catalysts are all less than 20 microns.

Embodiment 3

[0037] Weigh 1.22g (12.2wt%) of metal copper powder, 5.66g (56.6wt%) of cuprous oxide, and 3.12g (31.2wt%) of cupric oxide as the reaction raw materials. In a protective atmosphere, treat at 1000°C for 1h, and then Aged at 400°C for 15 hours, the product was pulverized and ball milled to obtain a ternary copper-based solid-solution catalyst; the composition of the obtained copper catalyst was analyzed by chemical method: 94.4% Cu, 5.1% Cu 2 O and 0.5% CuO. The particle diameters of the ternary copper catalysts are all less than 20 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com