Method for preparing monolayer cubic boron nitride grinding wheel by pressure welding

A technology of cubic boron nitride and pressure welding, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of reducing the service life of abrasive tools, failure to maintain, and difficult distribution of abrasive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

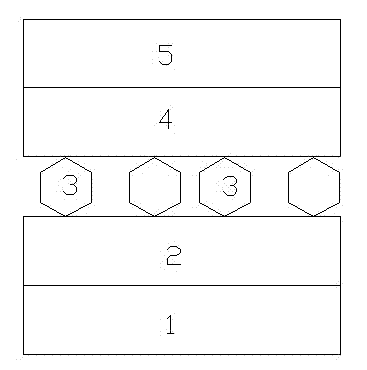

[0024] A method for preparing a single-layer cubic boron nitride grinding wheel by pressure welding, comprising the following steps:

[0025] (1) Select the grinding wheel base material 1 according to the relevant requirements for preparing single-layer cubic boron nitride grinding wheels, prepare the grinding wheel base 1 according to the size requirements by mechanical processing, and then remove the oxide skin on the surface of the grinding wheel base, and remove oil and rust; the grinding wheel base The materials are commonly used materials, such as 40Cr and 45# steel.

[0026] (2) Vacuum deposition is used to prepare an amorphous alloy bonding layer 2 with a certain thickness and uniform thickness on the surface of the clean grinding wheel substrate 1. The thickness of the amorphous alloy bonding layer 2 is 10-150 μm; the amorphous alloy is nickel-based or Copper-based and other amorphous alloy materials, the amorphous alloy contains active elements such as titanium that ...

Embodiment 2

[0032] A method for preparing a single-layer cubic boron nitride grinding wheel by pressure welding: the grinding wheel base is made of 45# steel, and the copper-based amorphous alloy Cu is vacuum-deposited 60 Zr 30 Ti 10 , The thickness of the bonding layer is about 1 / 2 of the diameter of the cubic boron nitride abrasive grain. The abrasive grains are arranged and fixed on the surface of the amorphous alloy bonding layer by artificial means, and ceramic pressing sheets and pressing substances are placed on the abrasive grains, and then placed in a vacuum furnace for heating. Heating to Cu 60 Zr 30 Ti 10 The supercooled liquid phase zone was kept warm for 30 minutes, and then rapidly cooled to room temperature to prepare a single-layer cubic boron nitride grinding wheel.

[0033] Others are the same as embodiment 1.

Embodiment 3

[0035] A method for preparing single-layer cubic boron nitride grinding wheel by pressure welding: 45# steel is used as the base of the grinding wheel, and amorphous alloy Cu is prepared by liquid phase quenching 60 f 25 Ti 15, The thickness of the bonding layer is about 1 / 2 of the diameter of the cubic boron nitride abrasive grain. The abrasive grains are arranged and fixed on the surface of the amorphous alloy bonding layer by artificial means, and ceramic pressing sheets and pressing substances are placed on the abrasive grains, and then placed in a vacuum furnace for heating. Heating to Cu 60 Hf 25 Ti 15 The supercooled liquid phase zone was kept warm for 40 min, and then rapidly cooled to room temperature to prepare a single-layer cubic boron nitride grinding wheel.

[0036] Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com