A resource utilization method of fly ash, steel slag and coal gangue

A technology of fly ash and coal gangue, applied in applications, home appliances, other home appliances, etc., can solve problems such as inability to repair the surface structure, uncompact structure, waste of resources, etc., and achieve simple manufacturing process, great social benefits and economical Benefits, the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

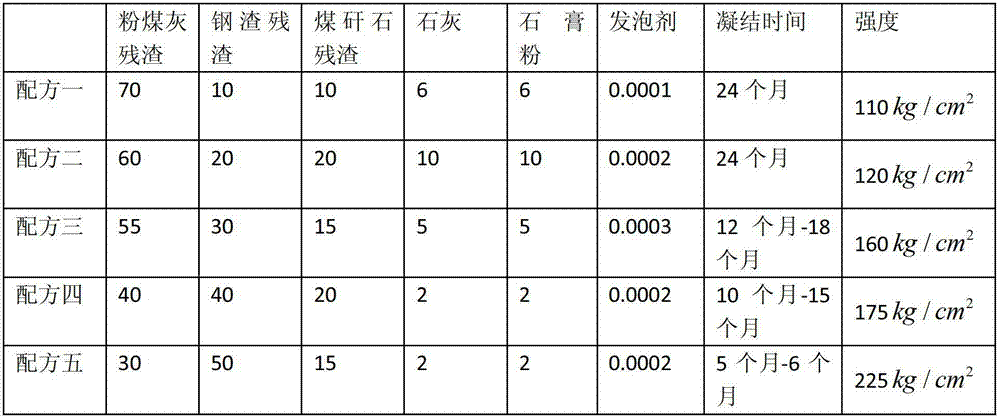

Examples

Embodiment 1

[0027]Embodiment 1 of the present invention. The resource utilization method of fly ash, steel slag and coal gangue comprises the following steps:

[0028] a. Blend the fly ash into slurry, and then sieve the slurry with a particle size of 24-300 mesh, then magnetically separate the slurry to select the iron ore in the fly ash, and the fly ash after magnetic separation The slurry is flotation to select bauxite, zinc ore, copper ore, molybdenum ore, tin ore and other valuable mineral resources in the fly ash. The specific minerals are determined according to the mineral content of each place. Flotation The method adopts the existing flotation method to obtain fly ash tailings mainly composed of silicon and calcium; the main components of fly ash are oxides of silicon, aluminum, iron and a small amount of other metals. According to the different geological conditions of each producing area, The minerals contained in fly ash are also different. Through the existing flotation pro...

Embodiment 2

[0033] Embodiment 2 of the present invention. The resource utilization method of fly ash, steel slag and coal gangue comprises the following steps:

[0034] a. Blend the fly ash into slurry, and then sieve the slurry with a particle size of 200 mesh, then magnetically separate the slurry to select the iron ore in the fly ash, and the fly ash slurry after magnetic separation Carry out flotation to select bauxite, zinc ore, copper ore, molybdenum ore, tin ore and other valuable mineral resources in fly ash, and obtain fly ash tailings mainly composed of silicon and calcium;

[0035] b. Grinding steel slag, mixing slurry, passing through a 200-mesh sieve, performing magnetic separation, selecting iron ore in steel slag, and obtaining steel slag tailings;

[0036] c. Grind coal gangue, pass it through a 200-mesh sieve, prepare slurry, and carry out flotation of the slurry to select bauxite, zinc ore, copper ore, molybdenum ore, tin ore, carbon and other valuables in coal gangue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com