Binder and method for molding calcium-base industrial powder based on binder

A binder and powder technology, applied in the field of calcium-based industrial powder molding and binder, can solve the problems of occupying land resources, waste of calcium resources, limited processing capacity of calcium carbide slag, etc. Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

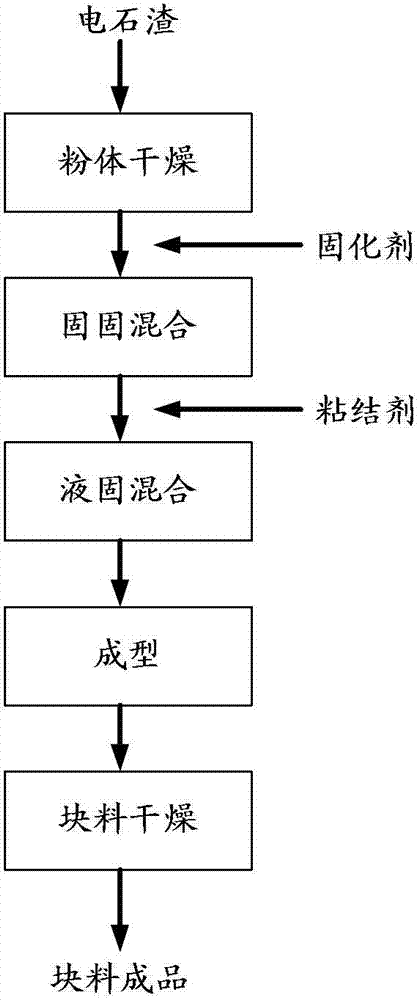

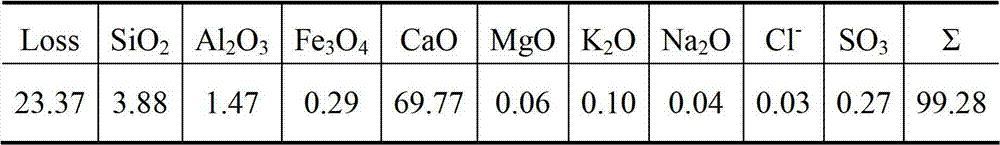

Method used

Image

Examples

Embodiment 1

[0053] First, mix hydrochloric acid and water with a mass ratio of 1:10 to make a dilute acid solution binder; weigh 48g of calcium carbide slag with a moisture content of 5% after drying, and fully mix it with 1g of sodium aluminate curing agent in a mortar; 0.24g dilute acid solution binder is fully mixed with the above solid powder, put into the grinding tool, at 300kg / cm 2 Press the pressure for 1min, take it out and dry it, and the heating rate is 1℃ / min when drying. The molded calcium carbide slag is cylindrical with a diameter of 28mm and a height of 28mm. The compressive strength in cold and hot states is greater than 300N / piece, and the thermal stability test at 850°C is greater than 65%.

Embodiment 2

[0055] First, mix phosphoric acid and water at a mass ratio of 1:15 to make a dilute acid solution binder; weigh 98g of calcium carbide slag with a water content of 20% after drying and add 1g of aluminum hydroxide to mix evenly; mix 11g of dilute acid solution binder Fully mix with the above solid powder, put it into the grinding tool, and use 500kg / cm 2 pressure, press for 2min, take out and dry, and the heating rate is 10°C / min during drying. The molded calcium carbide slag is cylindrical with a diameter of 28mm and a height of 28mm, and the compressive strength in hot and cold states is greater than 300N / piece.

Embodiment 3

[0057] First, mix potassium hydroxide and water with a mass ratio of 1:5 to make a dilute alkali solution binder; weigh 99g of calcium hydroxide powder with a water content of 5% after drying (calcium-based substance content is 95%); mix 1.98 g dilute alkali solution binder is fully mixed with the above solid powder, put into the grinding tool, and 2 Press the pressure for 1.5min, take it out and dry it, and the heating rate is 10℃ / min when drying. The molded calcium carbide slag is cylindrical with a diameter of 28mm and a height of 28mm. The compressive strength in cold and hot states is greater than 350N / piece, and the thermal stability test at 850°C is greater than 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com