Preparation method for lithium-ion battery anode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unsatisfactory cycle performance, low specific capacity of carbon materials, and large volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

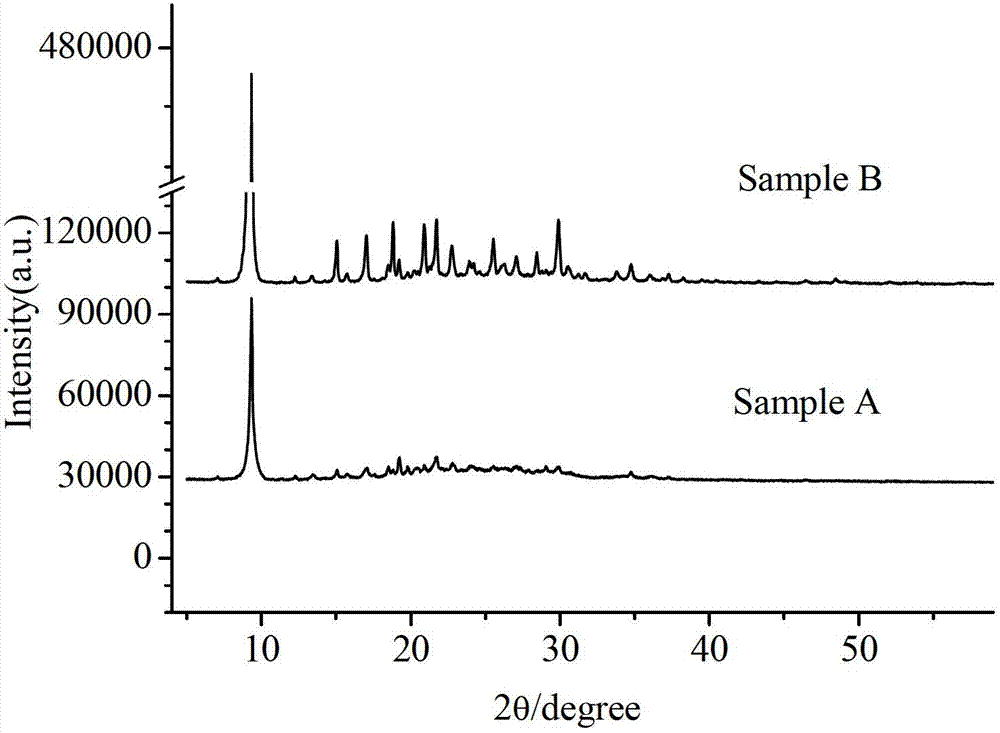

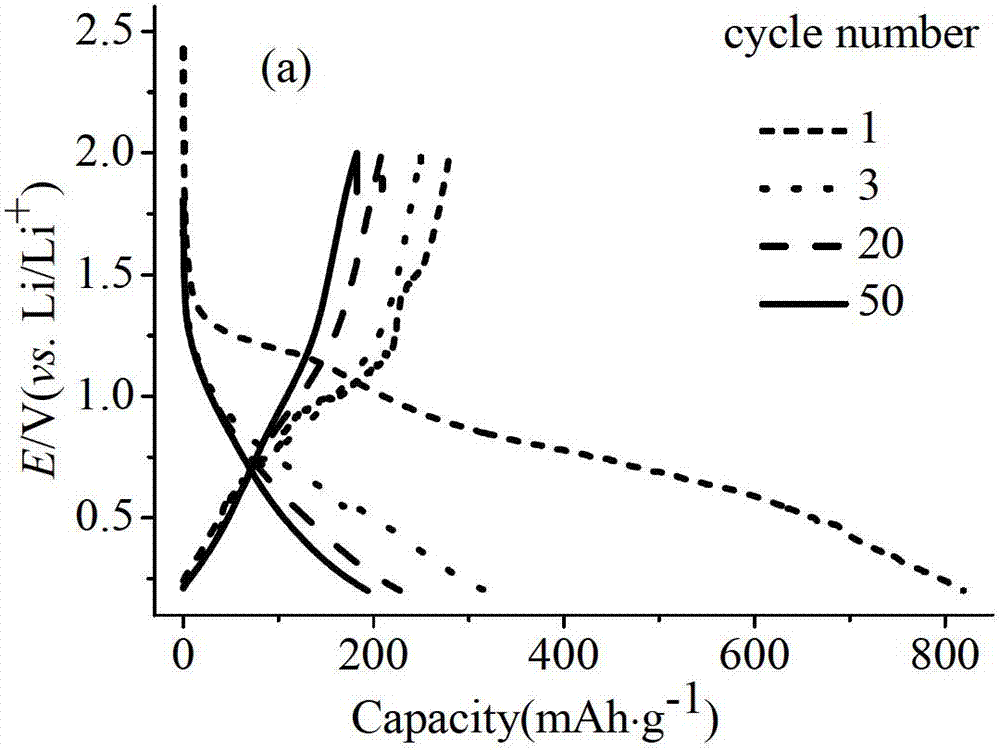

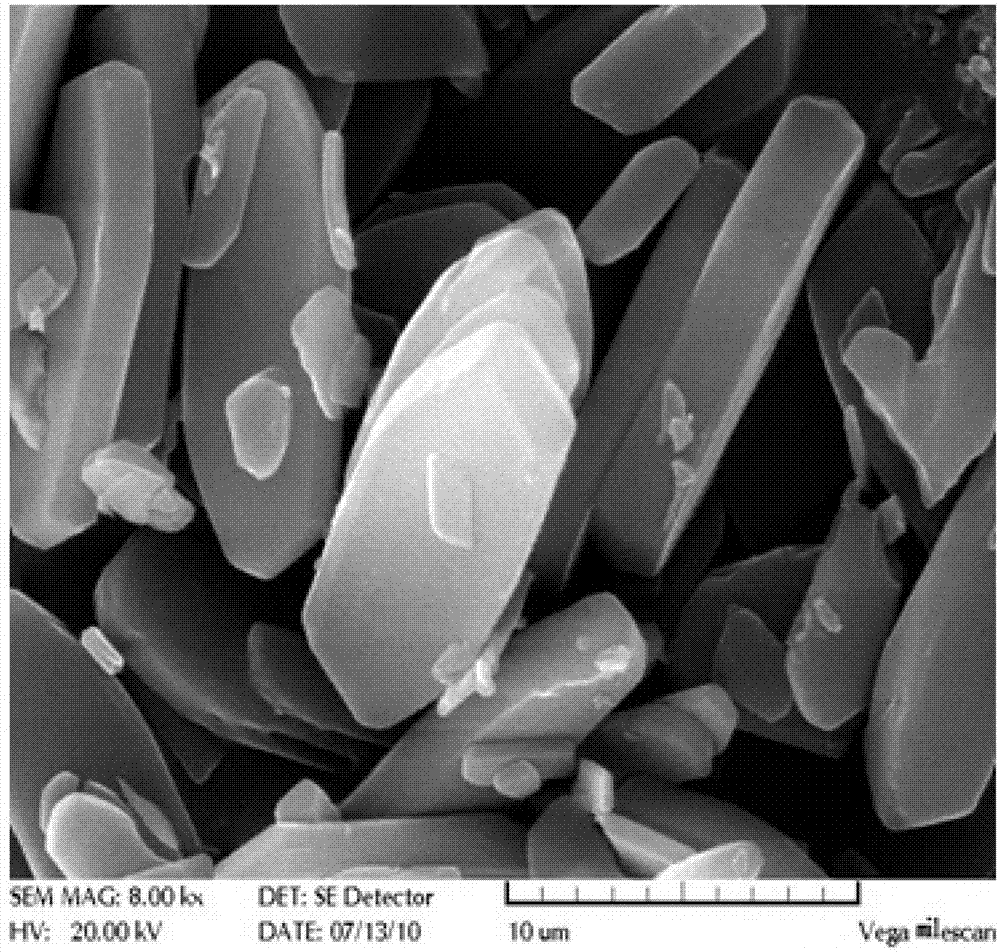

experiment example 1

[0017] Utilize reflux method to prepare lithium pyridinedicarboxylate powder of negative electrode material of lithium ion battery, concrete steps are as follows:

[0018] (1) First, add 0.167g (1mmol) of 2,6-pyridinedicarboxylic acid and 0.088g (2.1mmol) of LiOH·H to a 250mL three-neck flask 2 O powder, then add 100mL ethanol;

[0019] (2) Then, place the three-necked bottle in an oil bath at 70°C for a constant temperature reaction for 48 hours;

[0020] (3) The final product is filtered, washed and dried to obtain lithium 2,6-pyridinedicarboxylate as the negative electrode material for lithium ion batteries.

experiment example 2

[0022] Utilize reflux method to prepare lithium pyridinedicarboxylate powder of negative electrode material of lithium ion battery, concrete steps are as follows:

[0023] (1) First, add 0.167g (1mmol) of 2,5-pyridinedicarboxylic acid and 0.084g (2.0mmol) of LiOH·H to a 250mL three-necked flask 2 O powder, then add 100mL ethanol;

[0024] (2) Then, place the three-necked bottle in an oil bath at 70°C for a constant temperature reaction for 48 hours;

[0025] (3) The final product is filtered, washed and dried to obtain lithium 2,5-pyridinedicarboxylate as the negative electrode material for lithium ion batteries.

experiment example 3

[0027] Utilize reflux method to prepare lithium pyridinedicarboxylate powder of negative electrode material of lithium ion battery, concrete steps are as follows:

[0028] (1) First, add 0.167g (1mmol) of 3,4-pyridinedicarboxylic acid and 0.092g (2.2mmol) of LiOH·H to a 250mL three-necked flask 2 O powder, then add 100mL ethanol;

[0029] (2) Then, place the three-necked bottle in an oil bath at 70°C for a constant temperature reaction for 48 hours;

[0030] (3) The final product is filtered, washed and dried to obtain lithium 3,4-pyridinedicarboxylate as the negative electrode material for lithium ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com