Magnetic microzyme surface imprinted adsorbent for selectively separating cefalexin as well as preparation method and application thereof

A technology of cephalexin and surface imprinting, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., to achieve the effects of less by-products, high activity, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

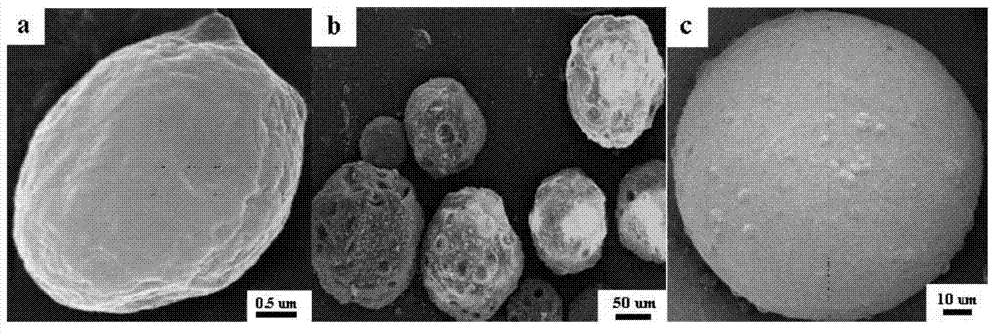

[0035] (1) Preparation of magnetic yeast composite material

[0036] Step A. Saccharomycetes is dispersed in saturated sodium chloride aqueous solution at normal temperature, the mass and volume ratio of yeast and saturated sodium chloride aqueous solution is 1g:5mL, forms yeast bacterium solution after mechanical stirring 30min;

[0037] Step B. take chitosan by weighing the ratio of 1g:35mL and be dispersed in 0.1mol / L acetic acid solution, mechanically stir 0.5h, form chitosan colloidal liquid;

[0038] Step C. The yeast solution is added to the chitosan colloidal liquid, the mass ratio of yeast to chitosan is 1:0.5 (g), and then adding the yeast mass ratio is 0.1: 1 (g) gamma-Fe 2 o 3 , after stirring for 1.5h, add paraffin oil and Span-80 with a volume ratio of 20:0.5 (mL), wherein the volume and mass ratio of paraffin oil to yeast is 100mL:1g, after emulsification for 20min, add dropwise with paraffin oil 25% (v / v) glutaraldehyde cross-linking agent with a volume ratio ...

Embodiment 2

[0051] (1) Preparation of magnetic yeast composite material

[0052] Step A. Disperse yeast in saturated aqueous sodium chloride solution at normal temperature, the mass and volume ratio of yeast to saturated aqueous sodium chloride solution is 1g:25mL, and form yeast solution after mechanical stirring for 30min;

[0053] Step B. take chitosan by weighing the ratio of 1g:60mL and be dispersed in 0.1mol / L acetic acid, mechanically stir for 0.5h, form chitosan colloidal liquid;

[0054] Step C. Add the yeast solution into the jelly liquid of chitosan, the mass ratio of yeast to chitosan is 1:2 (g), and then add the yeast with a mass ratio of 0.5 :1(g) of γ-Fe 2 o 3 , after stirring for 1.5h, add paraffin oil and Span-80 with a volume ratio of 20:2 (mL), wherein the volume and mass ratio of paraffin oil to yeast is 180mL:1g, after emulsification for 40min, add dropwise with paraffin oil 25% (v / v) glutaraldehyde cross-linking agent with a volume ratio of 1.5:25 (mL), cross-link...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com