Ternary copper catalyst prepared from copper powder recovered from waste organic silicon contacts and preparation method thereof

A technology of organosilicon waste contacts and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problems of high energy consumption, rising copper raw material prices, Problems such as high cost, to achieve the effect of reducing pollution, saving production cost, and easy to oxidize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

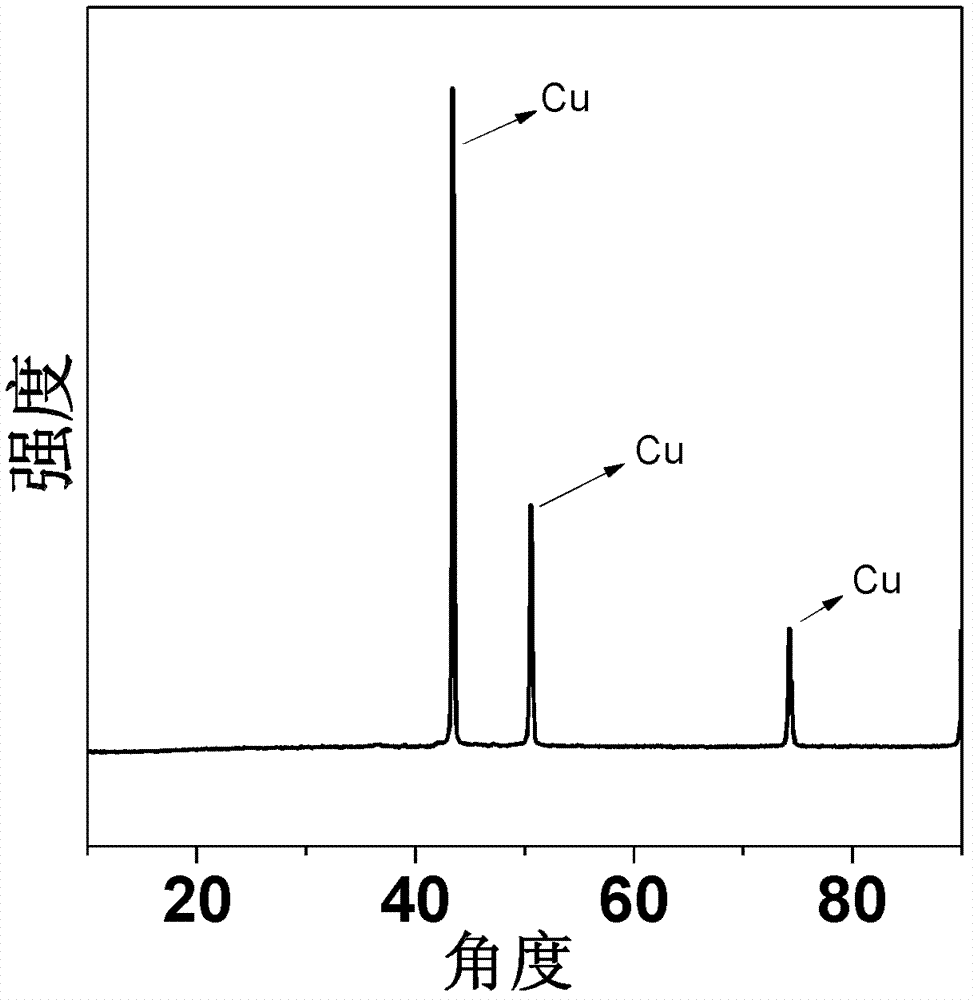

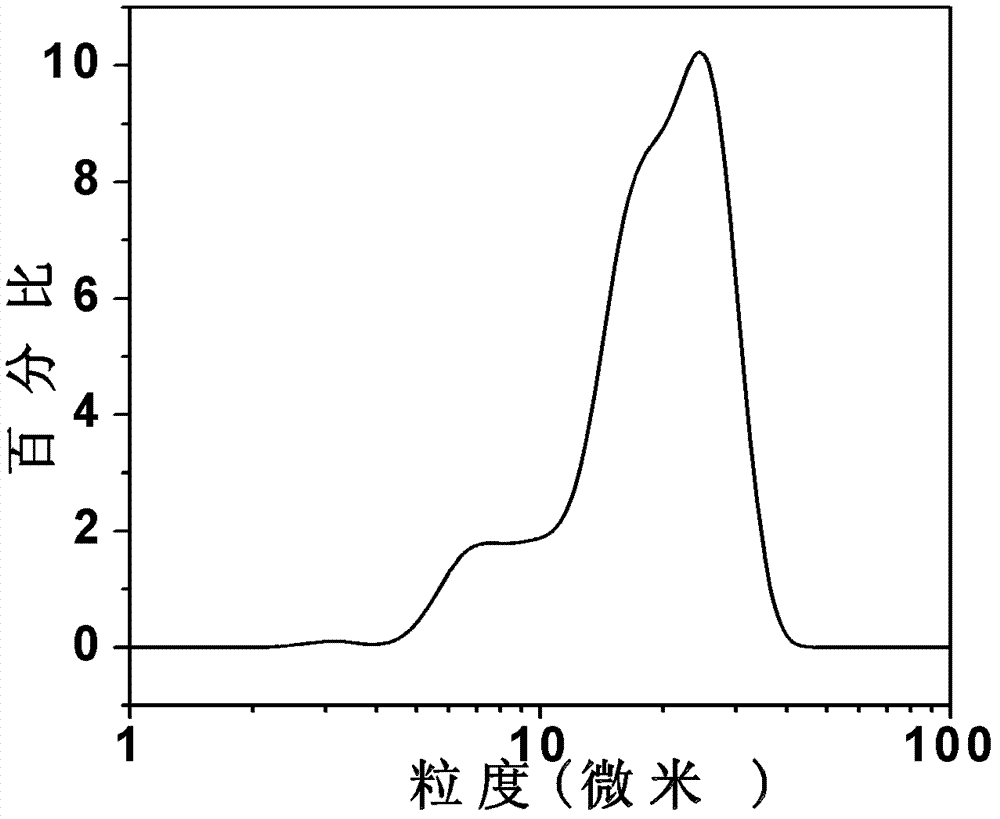

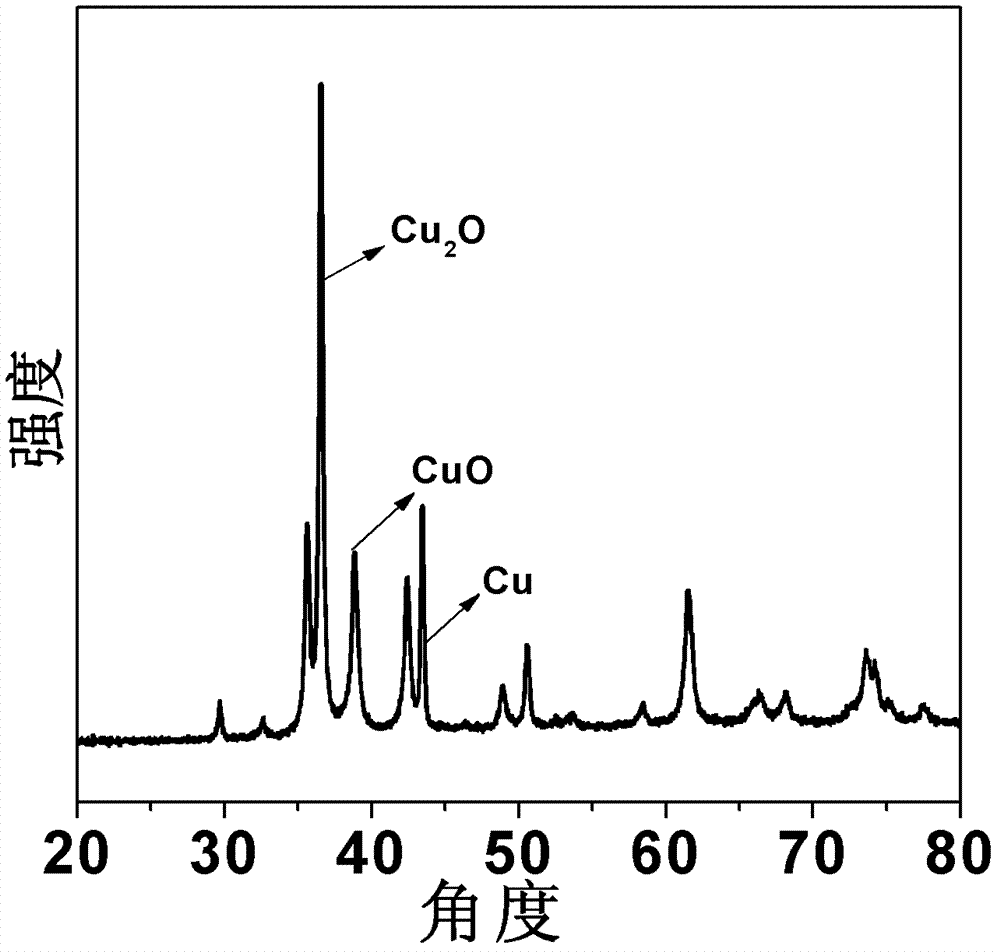

[0033]Weigh 100.0g waste contact body and add it to 300ml nitric acid solution (3mol / L), stir at 40°C for 5h, then filter under reduced pressure, raise the temperature of the filtrate to 80°C, add 14.0g reduced iron powder, and the solution immediately appears dark The red copper powder was filtered and washed after the reduction reaction was completed, and vacuum-dried at 80° C. for 12 hours to finally obtain 13.5 g of copper powder with a yield of 96%. The copper powder was put into a muffle furnace at 250° C. for calcination and oxidation, and the oxidation time was 4 hours to obtain 15.2 g of partially oxidized copper powder. Take 10.0g of partial copper oxide powder and put it into a ball mill, add 50.0g of ball milling beads (diameter φ=5mm) for ball milling, the ball milling time is 6h, filter and wash after the ball milling, and vacuum dry at 80°C for 12h to obtain the medium particle size (D50) It is a ternary copper catalyst of 1.8μm. Gained copper catalyst is compo...

Embodiment 2

[0041] Weigh 100.0g waste contact body and add it to 100ml concentrated sulfuric acid, stir at 60°C for 5h, then add 200ml deionized water to dilute, after vacuum filtration, heat the filtrate to 70°C, add 15.0g zinc powder, Dark red copper powder appeared immediately. After the reduction reaction was completed, it was filtered and washed, and vacuum-dried at 80° C. for 12 hours to finally obtain 13.3 g of copper powder with a yield of 95%. The copper powder was put into a muffle furnace at 300° C. for calcination and oxidation, and the oxidation time was 3 hours to obtain 15.0 g of partially oxidized copper powder. Take 10.0g of partial copper oxide powder and put it into a ball mill, add 50.0g of ball milling beads (diameter φ=5mm) for ball milling, the ball milling time is 6h, filter and wash after the ball milling, and vacuum dry at 80°C for 12h to obtain the medium particle size (D50) The ternary copper catalyst is 2.0μm. The obtained copper catalyst is composed as follo...

Embodiment 3

[0043] Weigh 100.0g of waste contact body and add it to 250ml of hydrochloric acid solution (3mol / L) containing 10g of hydrogen peroxide, stir at 20°C for 8h, then filter under reduced pressure, heat the filtrate to 80°C, add 14.0g of reduced iron powder, the solution Dark red copper powder appeared immediately in the solution. After the reduction reaction was completed, it was filtered and washed, and vacuum-dried at 80° C. for 12 hours to finally obtain 13.0 g of copper powder with a yield of 93%. The copper powder was put into a muffle furnace at 250° C. for roasting and oxidation, and the oxidation time was 4 hours to obtain 14.8 g of partially oxidized copper powder. Take 10.0g of partial copper oxide powder and put it into a ball mill, add 50.0g of ball milling beads (diameter φ=5mm) for ball milling, the ball milling time is 6h, filter and wash after the ball milling, and vacuum dry at 80°C for 12h to obtain the medium particle size (D50) The ternary copper catalyst is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com