Continuous preparation method for semi-aromatic polyamide

A technology for semi-aromatic polyamide and prepolymer, which is applied in the field of continuous preparation of semi-aromatic polyamide and achieves the effects of high product yield, stable process and rich variety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

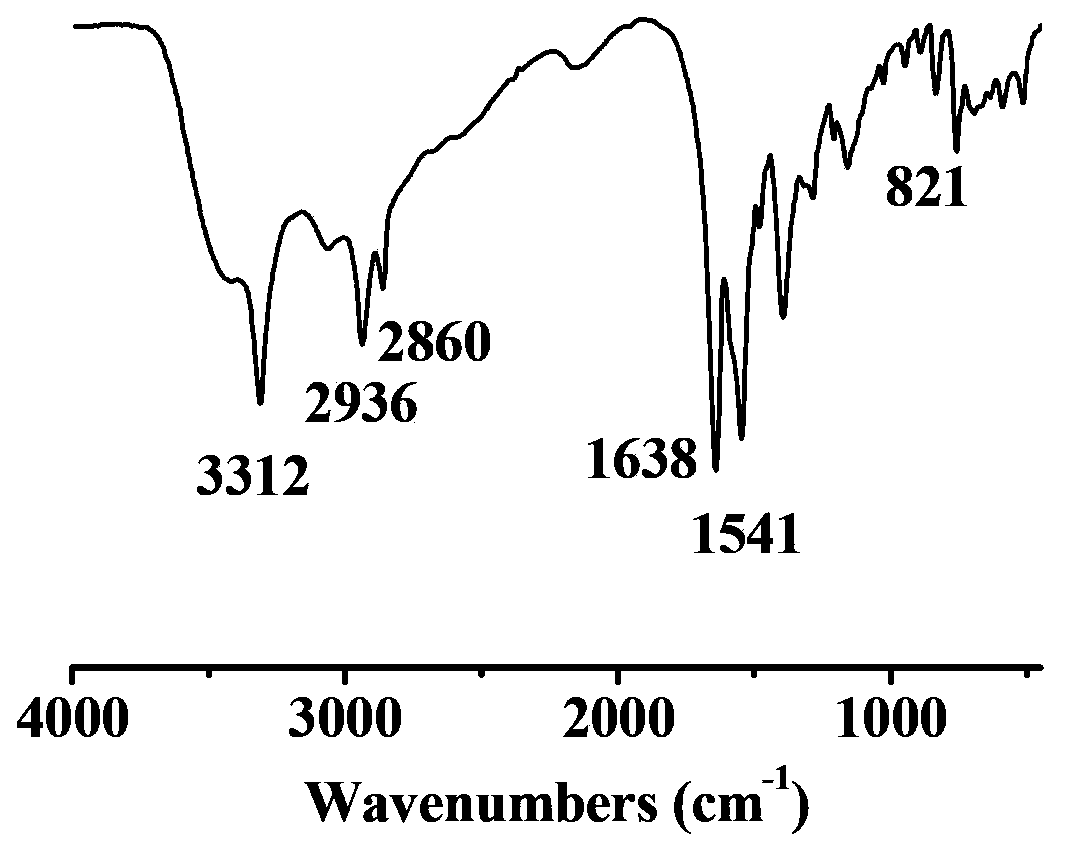

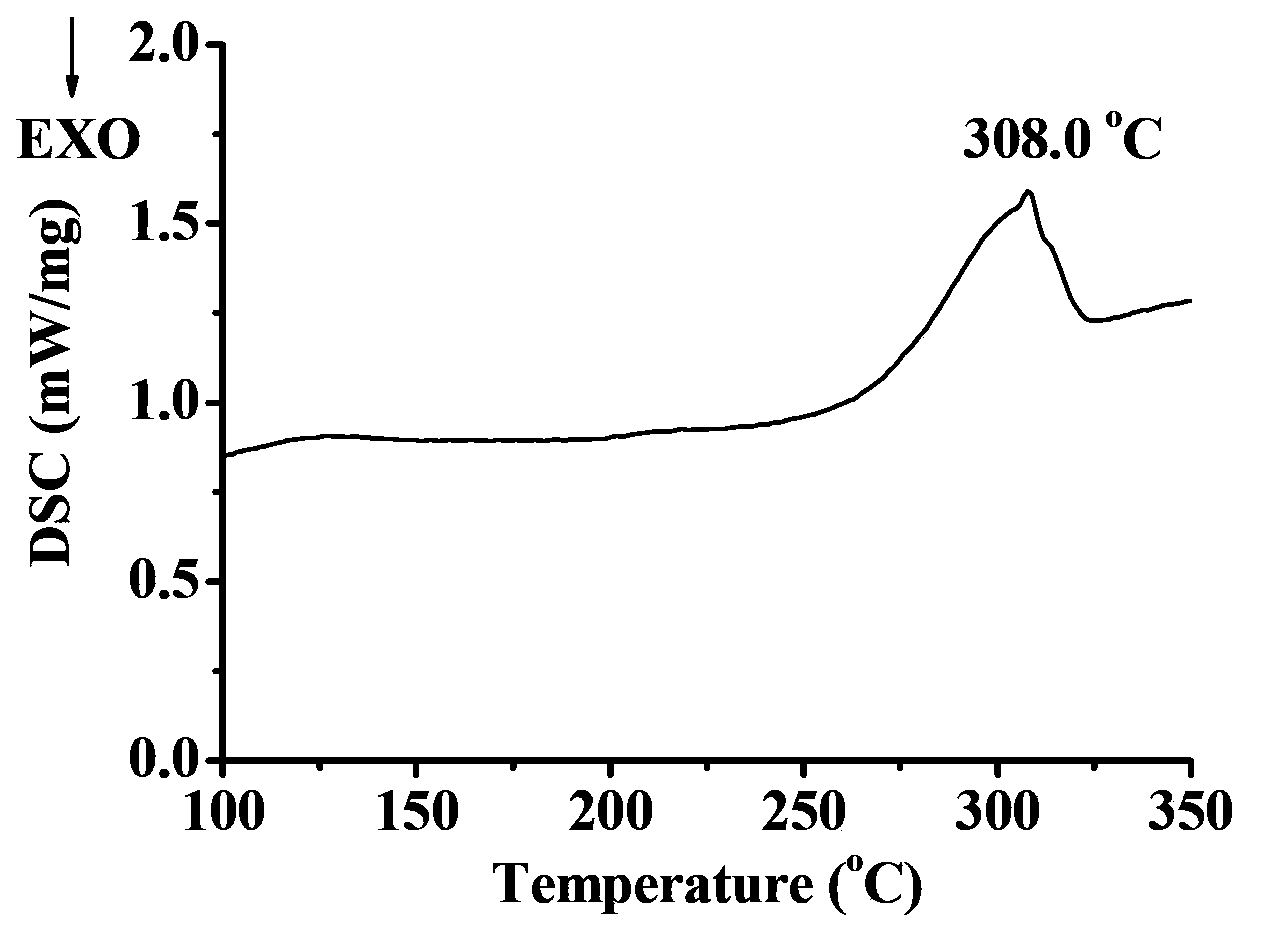

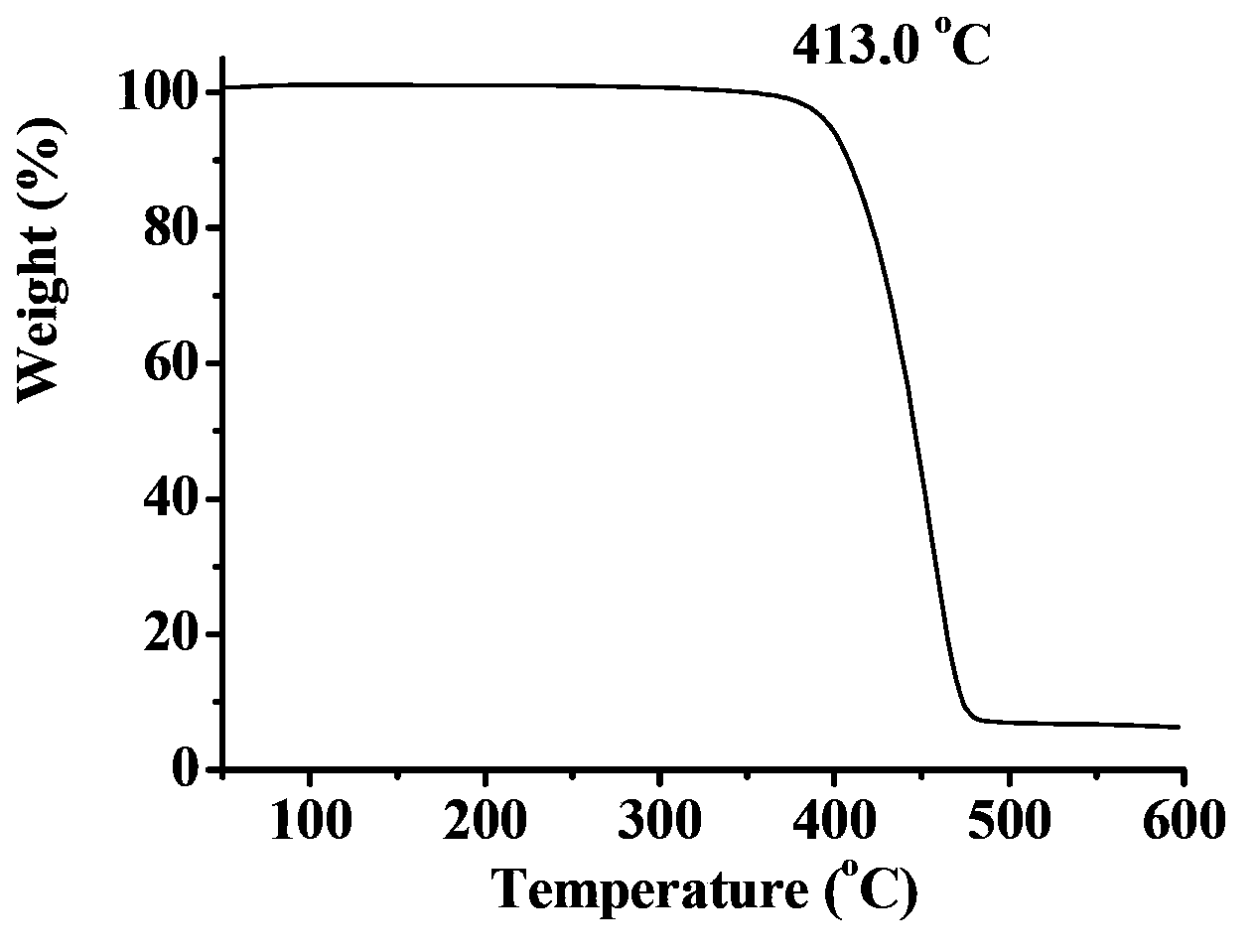

Image

Examples

Embodiment 1

[0042] Mix 20g / hour of phosphoric acid and semi-aromatic polyamide prepolymer (prepared by weight ratio of terephthalic acid: adipic acid: hexamethylenediamine = 83:73:116) 2500g / hour and feed it from the reaction extruder Feed port is added, benzoic acid 5g / hour and dispersion material 300g / hour are mixed and then added from the auxiliary feed port, and reacted and extruded at a temperature of 300°C, a screw speed of 180rpm and a vacuum of 0.07MPa; the extruded product is drawn, cooled, After pelletizing and drying, a semi-aromatic polyamide resin was obtained, with a yield of 96%, and intrinsic viscosity [η]=2.3dL·g -1 .

Embodiment 2

[0044]Mix pyrophosphoric acid 1g / hour and semi-aromatic polyamide prepolymer (prepared by weight ratio of hexamethylenediamine terephthalate:caprolactam=141:59) 1000g / hour and add it from the main feeding port of the reaction extruder , 1 g / hour of p-toluic acid and 100 g / hour of dispersion material are mixed and added from the auxiliary feeding port, and reacted and extruded at a temperature of 330 ° C, a screw speed of 10 rpm and a vacuum of 0.09 MPa; the extruded product is drawn, cooled, After pelletizing and drying, a semi-aromatic polyamide resin was obtained with a yield of 97% and an intrinsic viscosity [η]=1.9dL·g -1 .

Embodiment 3

[0046] Polyphosphoric acid 50g / hour and semi-aromatic polyamide prepolymer (by 4,4'-(4-thioether benzoic acid)-triphenylphosphine oxide: decyl diamine: cycloheptanolactam=582:172: 46 weight ratio preparation) 5000g / hour mixed and added from the main feeding port of the reaction extruder, m-toluic acid 10g / hour and dispersion material 500g / hour mixed and added from the auxiliary feeding port, at a temperature of 320 ° C, Reactive extrusion at a screw speed of 200rpm and a vacuum of 0.07MPa; the extrudate was drawn, cooled, pelletized and dried to obtain a semi-aromatic polyamide resin with a yield of 88% and an intrinsic viscosity [η]=1.6dL·g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com