High refractive index curable liquid light emitting diode encapsulant formulation

A technology of light-emitting diodes and sealants, applied in electroluminescent light sources, semiconductor/solid-state device parts, light sources, etc., can solve the problems of difficult processing of composites, uneven products, and inability to flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

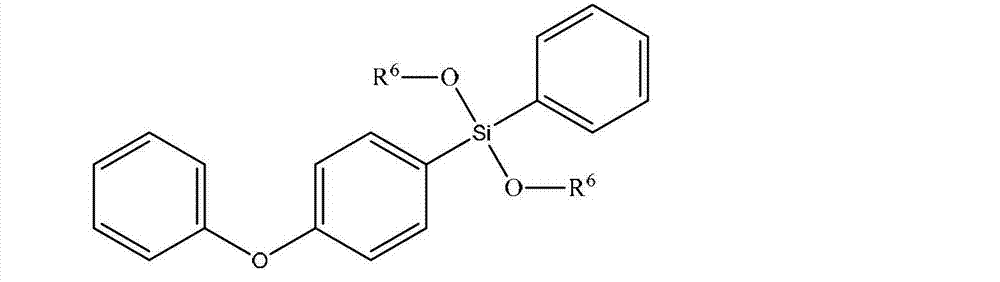

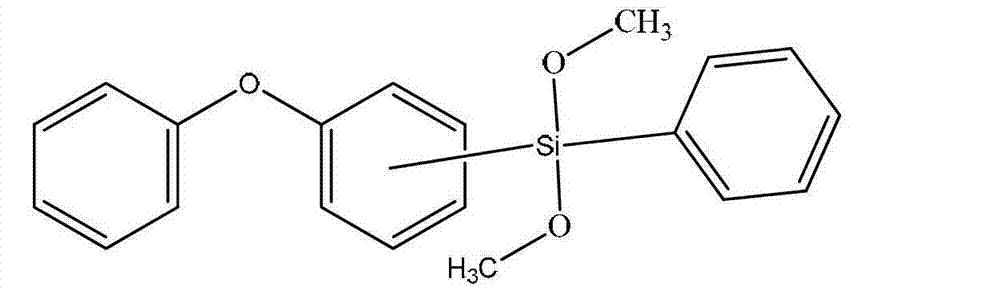

[0048] Embodiment 1: POP monomer preparation

[0049] To a 500 mL Schlenk flask was added diethyl ether (400 mL); metallic magnesium powder (3.3 g; 135 mmol); and methyl iodide (0.1 mL). 4-Bromodiphenylether (32.161 g; 129 mmol) was then added to the flask and the reaction mixture was stirred for 4 hours. Phenyltrimethoxysilane (25.601 g, 129 mmol) was then added to the flask and the contents were stirred for an additional hour. The contents of the flask were then transferred to a 1 liter separatory funnel and the material was washed twice with 400 ml of distilled water. The ether layer was collected and volatiles were removed under reduced pressure. The purity of the crude product was further purified by short-path distillation to obtain the product POP monomer with a purity ≥ 97%. The product POP monomer contains < 500 ppm of phenoxyphenyl halide.

Embodiment 9-12

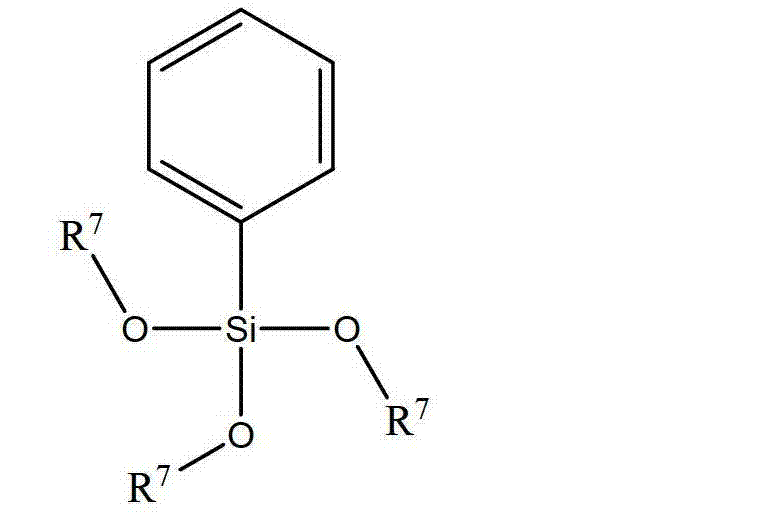

[0064] Examples 9-12: Curable Liquid Polysiloxane / TiO 2 Preparation of complex

[0065] Using the following general procedure, using the specific amounts shown in Table 3, a curable liquid polysiloxane / TiO 2 Complex. Specifically, the amounts of POP and PTMS shown in Table 3 and 15 ml of propylene glycol methyl ether acetate (PGMEA) were added to a 100 ml three-neck round bottom flask. A solution of 5 grams of methanol, 1 gram of water, and 0.16 grams of concentrated hydrochloric acid (37% in water, purchased from Fisher Scientific) was then added dropwise to the flask. The contents of the flask were then heated to 70°C and maintained at this temperature for 1.5 hours using a thermostatic heating mantle with a temperature probe and reflux condenser. Then through the addition funnel, the tetrabutyl titanate polymer (purchased from DuPont, trade name BTP) and 1 ml of anhydrous tetrahydrofuran (THF) were added dropwise into the flask, while maintaining the contents of ...

Embodiment VA

[0077] Embodiment VA and VC-VE, and embodiment V2-V11

[0078]In Comparative Examples VA and VC-VE and Examples V2-V11, Rheometric Scientific Inc. (now TA Instruments, New Castle, Delaware, USA) was used. ) RMS-800 Rheometrics Mechanical Spectrometer (Rheometrics Mechanical Spectrometer), the following general steps were used to measure the viscosity of the products prepared in Comparative Examples A and C-E, and Examples 2-11 respectively. Specifically, in each case, a sample of the material to be tested was loaded, sandwiching the sample of the material to be tested between two parallel aluminum plates with a diameter of 8 mm. The rheometer stand and plates were preheated to 60°C, equilibrated at this temperature for 15 minutes, and then the gap between the plates was zeroed. Then, for liquid samples with viscosities greater than 100 Pa-s, the temperature of the parallel plate was raised to 90°C to facilitate sample loading. After loading the sample material onto the bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com