Process for smelting vanadium-containing pig iron by high-silicon vanadium titanomagnetite concentrate powder

A vanadium-titanium magnetite, high-silicon technology, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with specific examples. The following examples do not limit the protection scope of the present invention, and all modifications and adjustments made based on the idea of the present invention belong to the protection scope of the present invention.

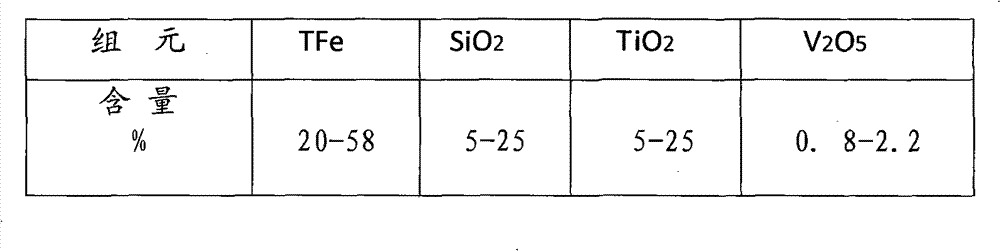

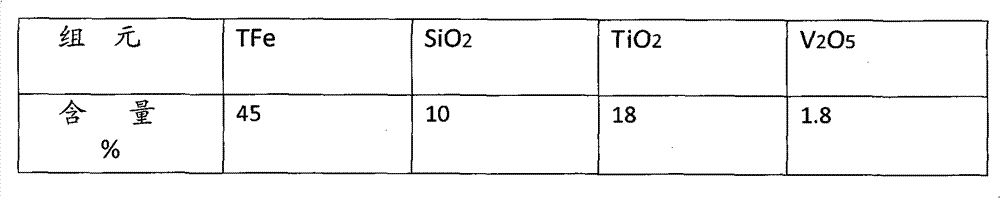

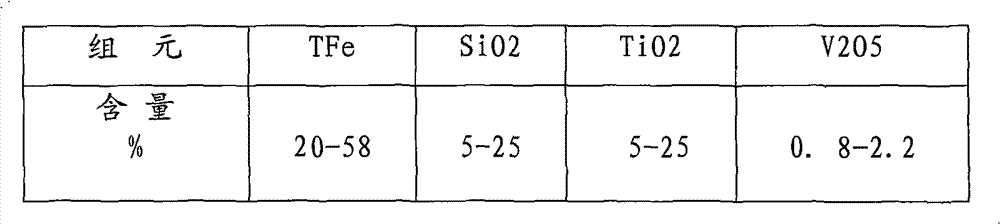

[0017] In an embodiment, the chemical average composition of high-silicon vanadium titano-magnetite fine powder is listed in the following table:

[0018]

[0019] Mix this high-silicon vanadium-titanium-magnetite fine powder with coke (coal) powder and lime powder in a weight ratio of 1:0.05:0.20, add water to the mixer, and make pellets with a particle size of 25-35 by a briquetting machine After a period of natural health preservation, carbon-containing cold-set pellets with qualified strength are obtained.

[0020] At the same time, the high-silicon vanadium-titanium magnetite fine powder is used as raw material to produce roasted acid pellets by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com