Preparation method and use of titanium-doped zinc-magnesium aluminate film

A zinc aluminate, titanium doping technology, applied in ion implantation plating, coating, electrical components and other directions, can solve the problems of single performance and poor luminescence performance of Mn materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

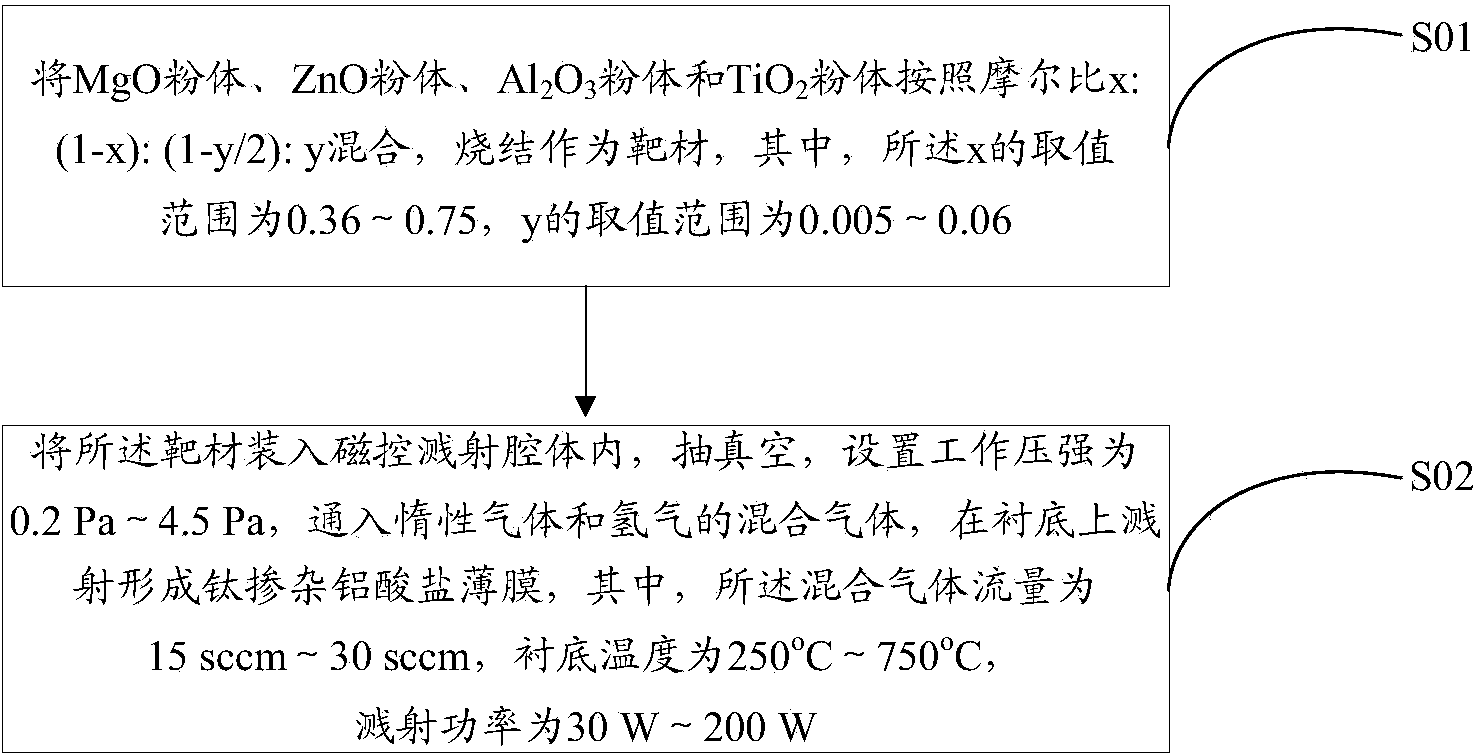

[0018] see figure 1 , showing a method for preparing a titanium-doped zinc-magnesium aluminate film according to an embodiment of the present invention, which includes the following steps:

[0019] S01: MgO powder, ZnO powder, Al 2 o 3 Powder and TiO 2 The powder is mixed according to the molar ratio x:(1-x):(1-y / 2):y, and sintered as the target material, wherein the value range of x is 0.36-0.75, and the value range of y is 0.005 ~0.06;

[0020] S02: Put the target material into the magnetron sputtering chamber, vacuumize, set the working pressure to 0.2Pa-4.5Pa, feed the mixed gas of inert gas and hydrogen, the flow rate of the mixed gas is 15sccm-30sccm, the substrate temperature The temperature is 250 ℃ ~ 750 ℃, the sputtering power is 30W ~ 200W, and the titanium doped zinc magnesium aluminate film is formed by sputtering;

[0021] In step S01, MgO powder, ZnO powder, Al 2 o 3 Powder and TiO 2 The powder is uniformly mixed according to the molar ratio x:(1-x):(1-y...

Embodiment 1

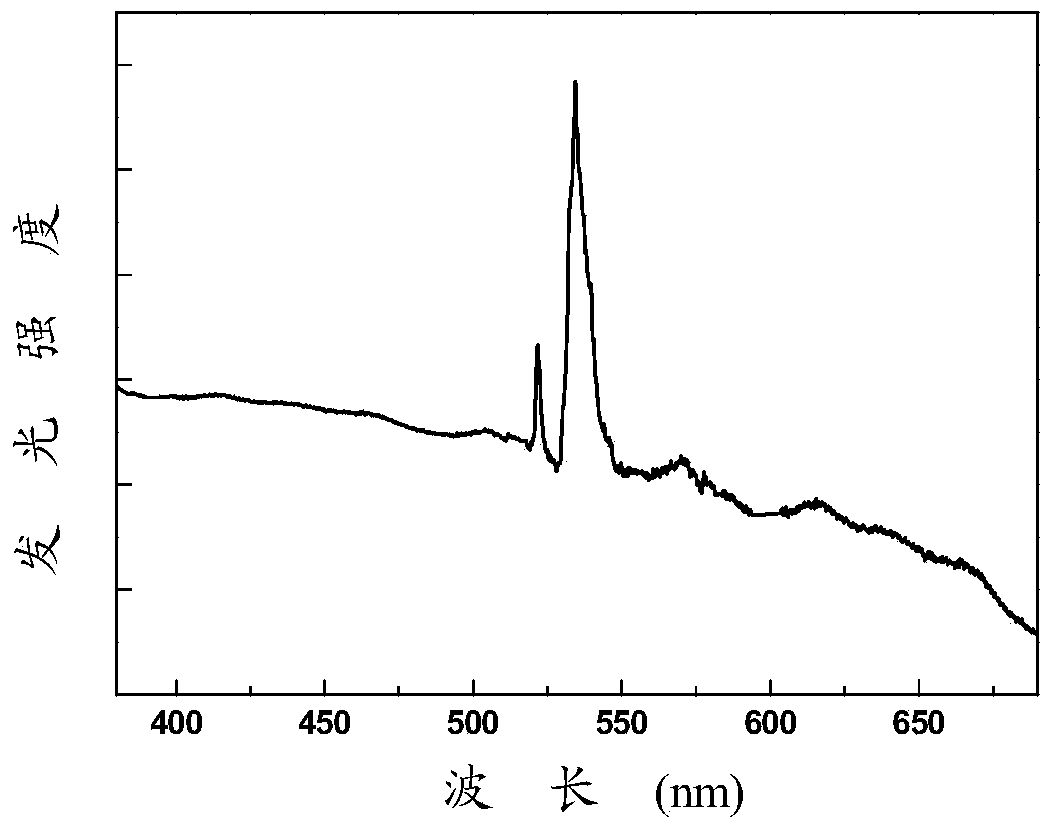

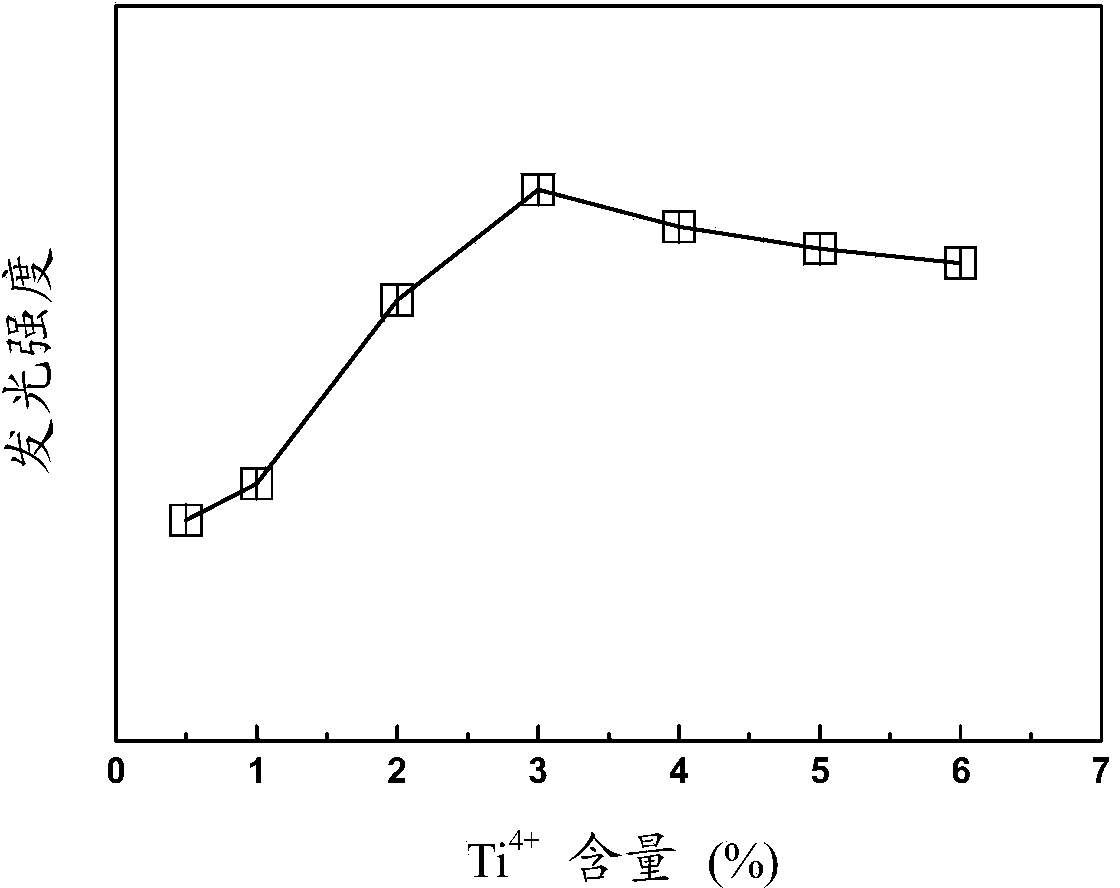

[0027] Choose ZnO powder, MgO powder, TiO with a purity of 99.99%2 Powder and Al 2 o 3 Powder, including MgO, ZnO, TiO 2 and Al 2 o 3 The masses are 20, 40.5, 98.9 and 2.4 g, respectively. After uniform mixing, high temperature sintering at 1250°C to form a Ф50×2mm ceramic target, and put the target into a vacuum chamber. Then, the quartz substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water, dried with high-purity nitrogen, and placed in a vacuum chamber. The distance between the target and the substrate is set to 75mm. Use a mechanical pump and a molecular pump to pump the vacuum of the cavity to 7.0×10 -4 Pa, the mixed gas of argon and hydrogen fed into the vacuum cavity, the gas flow rate is 25sccm, wherein the hydrogen content is 10% (volume percentage), the pressure is adjusted to 2.0Pa, the substrate temperature is set to 600°C, and the sputtering The radiation power was adjusted to 120W, and titanium-doped zinc-magnesium alumina...

Embodiment 2

[0029] Choose ZnO powder, MgO powder, TiO powder with a purity of 99.99% 2 Powder and Al 2 o 3 Powder, among them, MgO, ZnO, TiO 2 and Al 2 o 3 The masses are 14.4, 51.8, 101 and 0.4g, respectively. After uniform mixing, high temperature sintering at 1250°C to form a Ф50×2mm ceramic target, and put the target into a vacuum chamber. Then, the quartz substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water, dried with high-purity nitrogen, and placed in a vacuum chamber. The distance between the target and the substrate is set to 75mm. Use a mechanical pump and a molecular pump to pump the vacuum of the cavity to 7.0×10 -4 Pa, the mixed gas of argon and hydrogen fed into the vacuum cavity, the gas flow rate is 25 sccm, wherein the hydrogen content is 1% (volume percentage), the pressure is adjusted to 2.0Pa, the substrate temperature is set to 400 °C, and the sputtering The radiation power was adjusted to 120W, and titanium-doped zinc-magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Excitation wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com