Fire coal flue gas wet method energy-saving desulfurization method

A coal-fired flue gas, wet process technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of polluted environment, insufficient desulfurization, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

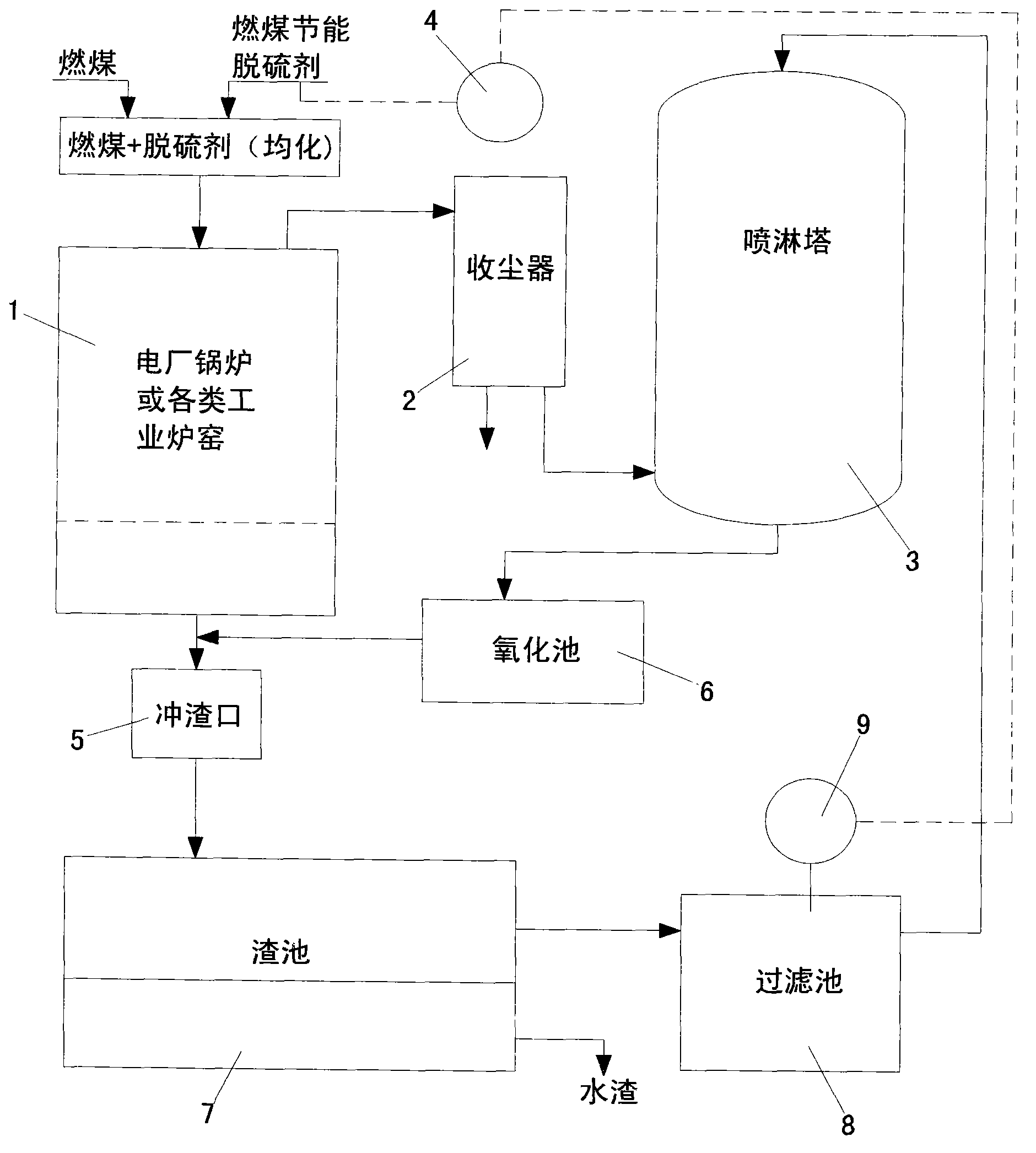

[0016] combine figure 1 As shown, the coal-fired flue gas wet energy-saving desulfurization method of the present invention comprises the following steps:

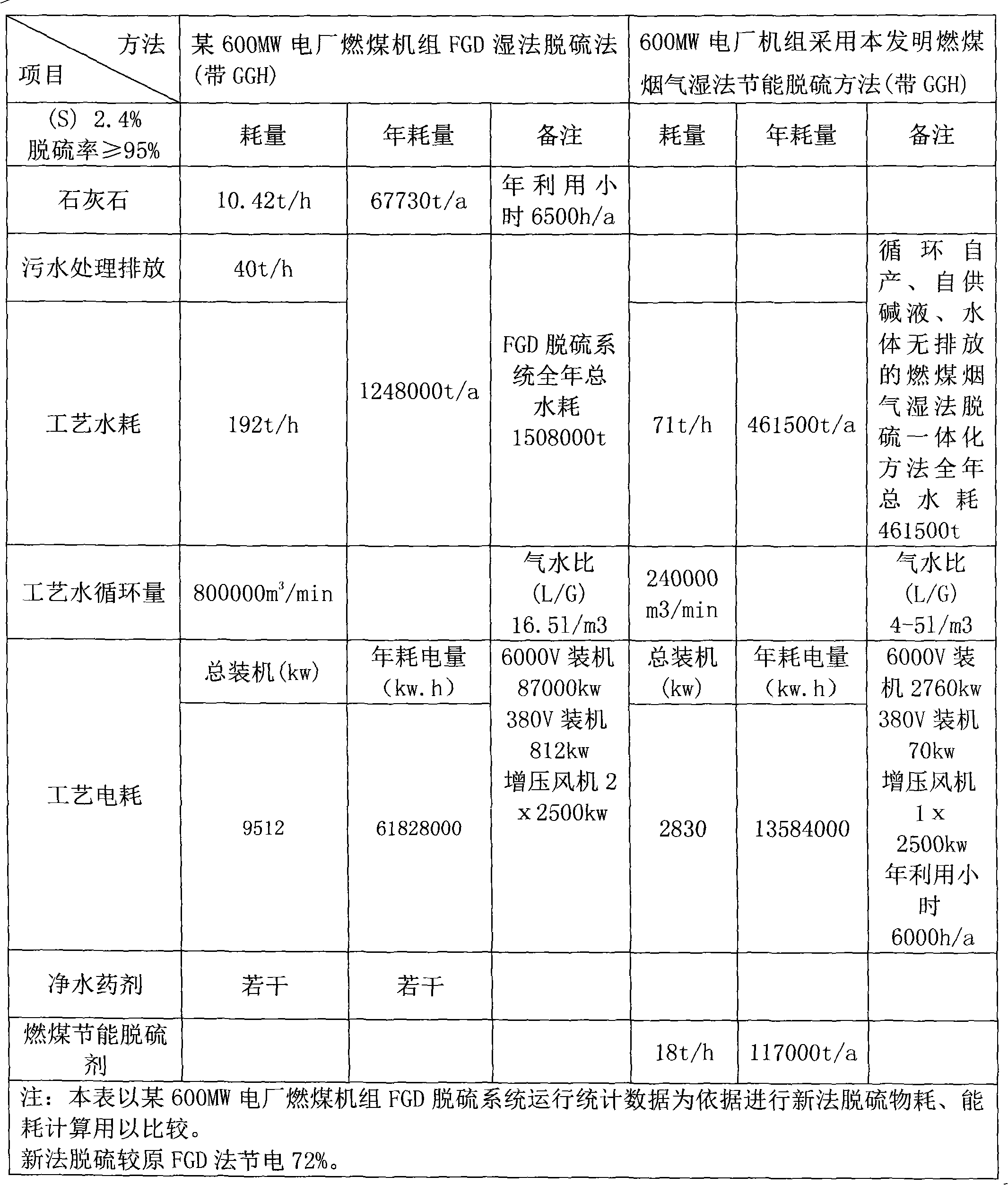

[0017] (1) Send the coal-fired energy-saving desulfurizer together with the coal-fired homogenizer into the power plant boiler or various industrial furnaces 1 for combustion. Furnace volume controller 4 is connected with the control system, so that the amount of coal-fired energy-saving desulfurizer is completely controlled by the control system, and the gas and liquid phase media realize the interaction of chemical reaction and physical adsorption during the combustion process, and the combustion in the furnace SO produced by the reaction 2 Transformation with the elements in the furnace charge produces a variety of different compounds including a variety of soluble sulfates. These compounds and unreacted charge are discharged out of the furnace with the slag. This process can complete the active desulfurization and sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com