Gas separation membrane for dme production process

A technology of gas separation membrane and production process, which is applied in the fields of hydrogen separation, gas treatment, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

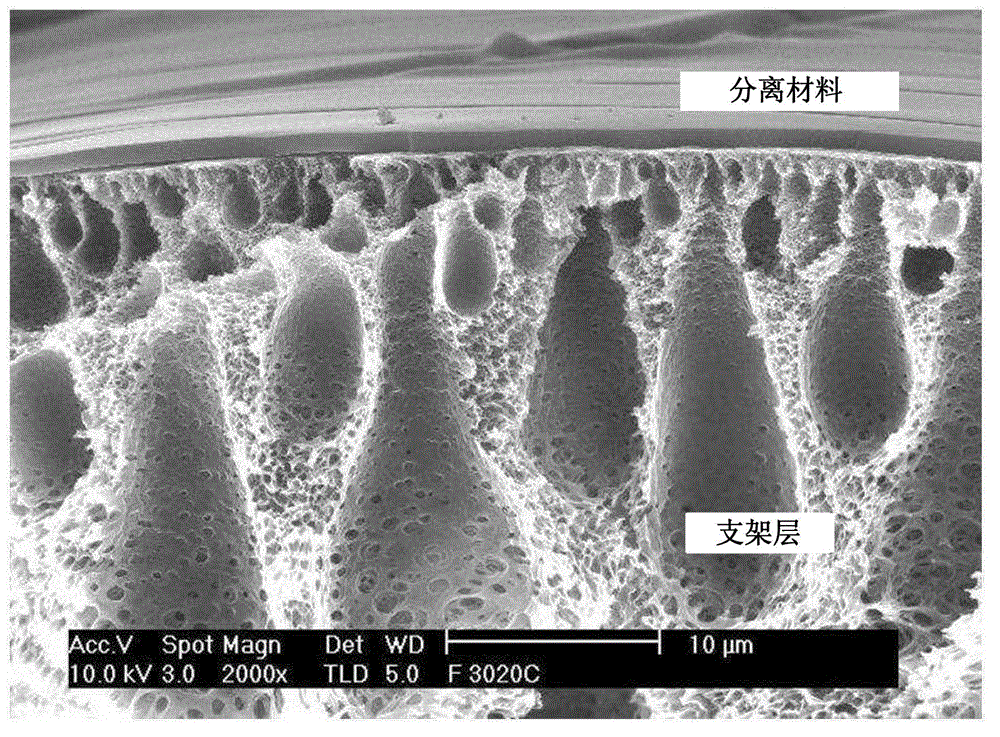

[0060] (a) Preparation of hollow fiber membrane

[0061] 20g polyetherimide (Sabic-IP company, Ultem TM ), 20 g of tetrahydrofuran (first additive) and 20 g of ethanol (second additive) were sequentially and slowly added dropwise to 40 g of N-methylpyrrolidone (solvent) while stirring the solvent, thus preparing a uniform spinning solution. Subsequently, air bubbles were removed from the spinning solution at room temperature and reduced pressure for 24 hours, and then foreign materials were removed from the spinning solution with a 60 μm filter. Subsequently, the spinning solution was spun at a temperature of 60° C. with a cylinder pump at a flow rate of 7 cc / min. Here, the air gap was 10 cm, a double spinneret was used, and water was used as a coagulant. Further, the inner diameter and the outer diameter of the inner nozzle of the double spinning head were 0.4 mm and 0.8 mm, respectively, and the diameter of the outer nozzle of the double spinning head was 1.2 mm. Subseque...

Embodiment 2

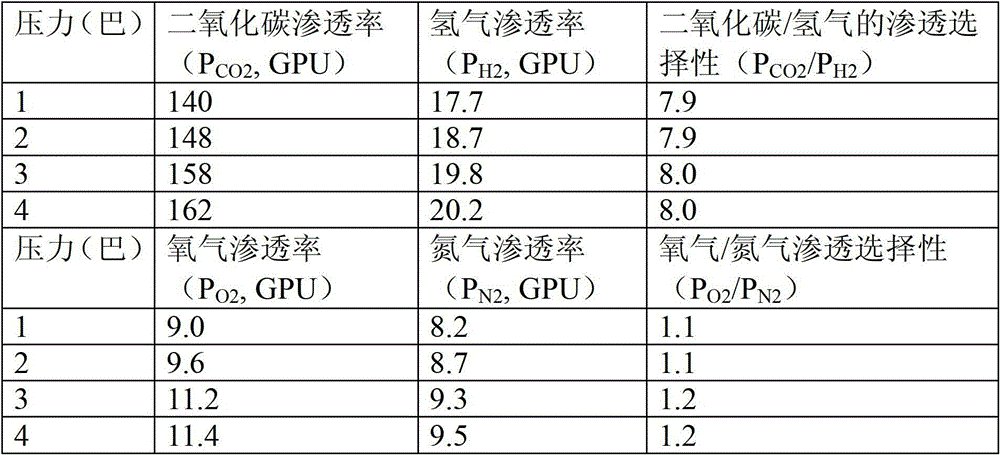

[0069] The hollow fiber membrane prepared in the same manner as in Example 1 was unwound from the bobbin, and then immersed in a 5% polyethylene oxide-urethane coating solution (solvent: n-butane) at room temperature for 5 seconds or longer , while maintaining a constant tension to fabricate a gas separation membrane comprising a composite membrane coated with a separation material. A gas separation membrane module was manufactured using the manufactured gas separation membrane, and then the performance of the gas separation membrane module was evaluated in the same manner as in Example 1. The results are given in Table 2 below.

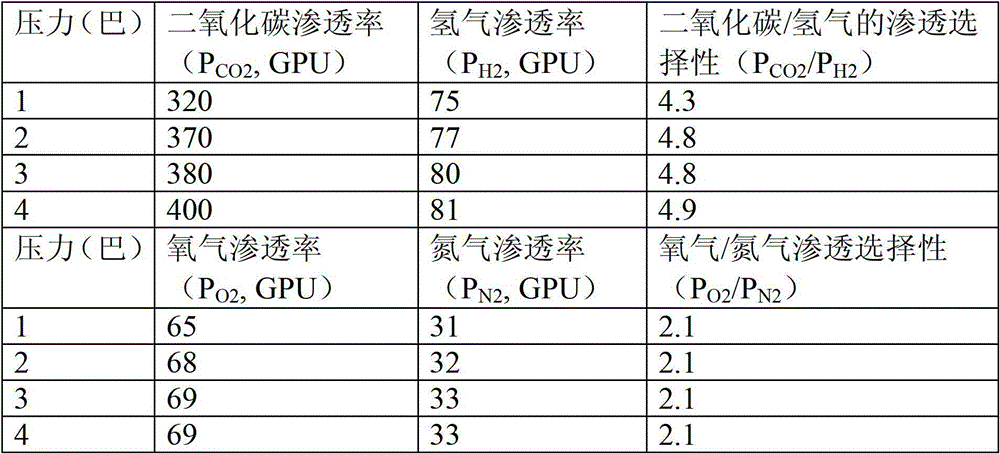

[0070] 【Table 2】

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com