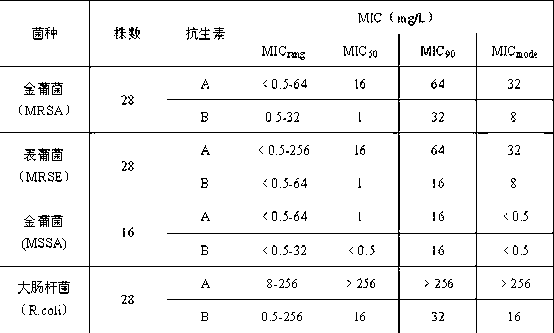

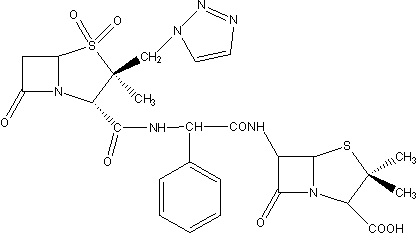

Tazobactam ampicillin amide composite, its preparation method and application

A technology of zobactam ampicillin amide and ampicillin trihydrate, which is applied in the pharmaceutical field and achieves good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Measure 100 mL of ethyl acetate, add 1 mmol of tazobactam, 3 mmol of N-hydroxysuccinimide (NHS), and 3 mmol of dicyclohexylcarbodiimide (DCC), fill with nitrogen, and stir Add 1mmol ampicillin trihydrate in batches, and stir for 24 hours at 5°C. After the reaction is completed, slowly pour the reactant into ice water under stirring, crystallize, filter with suction, and filter the cake with cold water and cold absolute ethanol in turn. washing. Pumping to dryness, and drying under reduced pressure, the crude product (I) was obtained as a white powdery solid. The crude product was added in batches to absolute ethanol at 50°C under stirring. After it was completely dissolved, it was cooled to room temperature in a water bath, and needle-like crystals were precipitated. Then cool it down to minus 15°C with an ice-salt bath and keep it warm for 3 hours. After suction filtration, the filter cake was washed twice with a small amount of cold absolute ethanol, and...

Embodiment 2

[0024] Example 2: Measure 150 mL of dioxane, add 2 mmol of tazobactam, 2 mmol of N-hydroxysuccinimide (NHS), and 2 mmol of dicyclohexylcarbodiimide (DCC), and fill with nitrogen to protect. Add 1mmol ampicillin trihydrate in batches under stirring, and stir for 5 hours at 30°C. After the reaction is completed, slowly pour the reactant into ice water under stirring, crystallize, and filter with suction. The filter cake is washed with cold water and cold anhydrous Ethanol wash. Pumping to dryness, and drying under reduced pressure, the crude product (I) was obtained as a white powdery solid. The crude product was added in batches to absolute ethanol at 60°C under stirring. After it was completely dissolved, it was cooled to room temperature in a water bath, and needle-like crystals were precipitated. Cool to 0°C with an ice-salt bath and keep warm for 1 hour. After suction filtration, the filter cake was washed twice with a small amount of cold absolute ethanol, and then drie...

Embodiment 3

[0025] Example 3: Measure 100mL of tetrahydrofuran and dioxane (1:1) mixed solvent, add 1.5mmol of tazobactam, 3mmol of N-hydroxysuccinimide (NHS), 5mmol of dicyclohexylcarbodiimide (DCC), under nitrogen protection, add 1mmol ampicillin trihydrate in batches under stirring, and stir for 12 hours at 20°C. After the reaction is completed, slowly pour the reactant into ice water while stirring, crystallize, suction filter, and filter The cake was washed successively with cold water and cold absolute ethanol. Pumping to dryness, and drying under reduced pressure, the crude product (I) was obtained as a white powdery solid. The crude product was added to absolute ethanol at 80°C in batches under stirring. After it was completely dissolved, it was cooled to room temperature in a water bath, and needle-like crystals were precipitated. Then cool it to minus 10°C with an ice-salt bath and keep it warm for 3 hours. After suction filtration, the filter cake was washed twice with a sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com