Preparation method of carbaryl molecular imprinting composite membrane

A carnacarb molecular and molecular imprinting technology, which is applied in the field of molecularly imprinted composite membranes, can solve the problems that samples cannot be effectively purified, residual carbaryl cannot be effectively enriched, complicated steps, etc., and achieves low manufacturing and use costs, The effect of high recovery and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

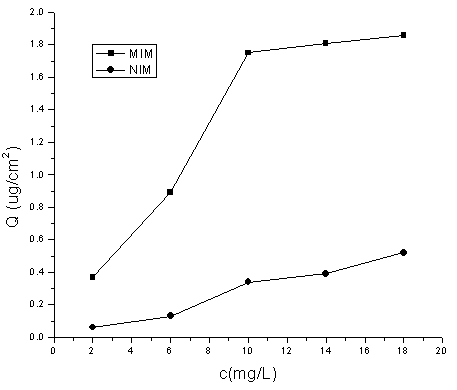

Image

Examples

Embodiment 1

[0020] 1. Preparation of Carbaryl MIM

[0021] Immerse the PVDF circular filter membrane in 10mg / mL AIBN solution for 5min, take it out and dry it in a vacuum desiccator. Dissolve 0.1mmol of carbaryl in 1.5mL of dichloromethane, add 0.6mmol of 4-VP and 2.5mmol of EGDMA in turn, ultrasonically oscillate for 5min, and then pass nitrogen for 10min; then immerse the PVDF membrane coated with the initiator into the mixture solution, placed under a 365nm ultraviolet lamp and irradiated for 12 hours, and the prepared composite membrane was repeatedly washed with a mixed solvent of methanol-acetic acid with a volume ratio of 9:1 until carbaryl and impurities were not detected in the eluent, and then used Excess acetic acid was washed away with methanol to obtain carbaryl MIM with PVDF as the supporting membrane, which was stored in dichloromethane for future use.

[0022] Selective separation of carbaryl residues in vegetable samples using biscarbaline MIM

[0023] Weigh 20g of blan...

Embodiment 2

[0026] 1. Preparation of Carbaryl MIM

[0027] Immerse the PVDF circular filter membrane in 10mg / mL AIBN solution for 5min, take it out and dry it in a vacuum desiccator. Dissolve 0.1 mmol of carbaryl in 1.5 mL of dichloromethane, add 0.4 mmol of 4-VP and 2.2 mmol of EGDMA in sequence, ultrasonically oscillate for 5 min, and then pass nitrogen gas for 10 min. Then immerse the PVDF membrane coated with the initiator in the mixed solution, and irradiate it under a 365nm ultraviolet lamp for 10 hours. The prepared composite membrane is washed repeatedly with a mixed solvent of methanol-acetic acid with a volume ratio of 9:1 until it reaches the eluent. Until no carbaryl and impurities are detected, the excess acetic acid is washed away with methanol to obtain carbaryl MIM with PVDF as the support membrane, which is stored in dichloromethane for future use.

[0028] Selective separation of carbaryl residues in vegetable samples using biscarbaline MIM

[0029] Weigh 20g of blank ...

Embodiment 3

[0032] 1. Preparation of Carbaryl MIM

[0033] Immerse the PVDF circular filter membrane in 10mg / mL AIBN solution for 5min, take it out and dry it in a vacuum desiccator. Dissolve 0.1 mmol of carbaryl in 1.5 mL of dichloromethane, add 0.8 mmol of 4-VP and 2.4 mmol of EGDMA in turn, ultrasonically oscillate for 5 min, and then pass nitrogen gas for 10 min, then immerse the PVDF membrane coated with the initiator into the mixture solution, placed under a 365nm ultraviolet lamp and irradiated for 11 hours, and the prepared composite film was repeatedly washed with a mixed solvent of methanol-acetic acid with a volume ratio of 9:1 until carbaryl and impurities were not detected in the eluent, and then used Excess acetic acid was washed away with methanol to obtain carbaryl MIM with PVDF as the supporting membrane, which was stored in dichloromethane for future use.

[0034] Selective separation of carbaryl residues in vegetable samples using biscarbaline MIM

[0035] Weigh 20g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com