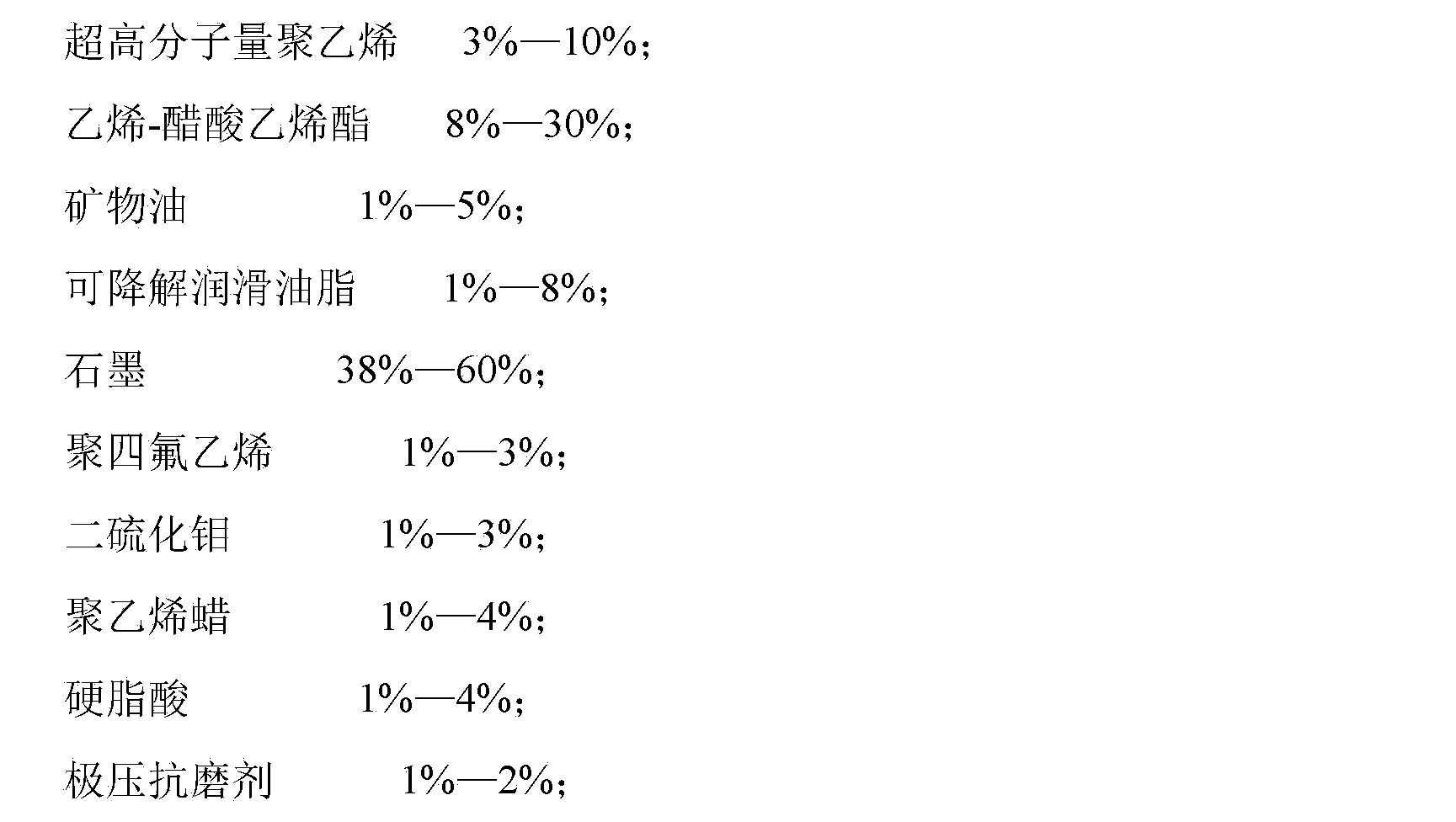

Composite solid lubricating bar shell and preparation method thereof

A kind of lubricating rod and composite technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of no practical application value, low mechanical strength of solid lubricants, easy to break, etc., to achieve low friction coefficient and reduced friction coefficient. Small, the effect of improving lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A composite solid lubricating stick shell of this embodiment is prepared from the following raw materials in weight percentage: ultra-high molecular weight polyethylene 5%; ethylene-vinyl acetate 20%; mineral oil 5%; degradable lubricating grease 7% ; Graphite 47%; PTFE 3%; molybdenum disulfide 3%; polyethylene wax 4%; stearic acid 4%; extreme pressure antiwear agent 2%. Molybdenum disulfide as a solid lubricant can reduce the friction coefficient. The ultra-high molecular weight polyethylene is white fine powder particles, and its average molecular weight is 1.5-2.5 million. The ethylene-vinyl acetate is a transparent particle, and the melt flow rate is 0.5 g / 10min-3 g / 10min. Described mineral oil is 500SN paraffin oil. The degradable lubricating grease is a degradable lubricating grease prepared from epoxy-esterification modified soybean oil. The polytetrafluoroethylene is superfine powder with a bulk density of 0.5Kg / l, an average particle size of 6±1μm, and a...

Embodiment 2

[0045] A composite solid lubricating rod shell of this embodiment is prepared from the following raw materials in weight percentage: ultra-high molecular weight polyethylene 10%; ethylene-vinyl acetate 18%; mineral oil 5%; degradable lubricating grease 8% ; Graphite 46%; PTFE 3%; molybdenum disulfide 2%; polyethylene wax 4%; stearic acid 3%, extreme pressure antiwear agent 1%. Molybdenum disulfide as a solid lubricant can reduce the friction coefficient. The ultra-high molecular weight polyethylene is white fine powder particles, and its average molecular weight is 1.5-2.5 million. The ethylene-vinyl acetate is a transparent particle, and the melt flow rate is 0.5 g / 10min-3 g / 10min. Described mineral oil is 500SN paraffin oil. The degradable lubricating grease is a degradable lubricating grease prepared from epoxy-esterification modified soybean oil. The polytetrafluoroethylene is superfine powder with a bulk density of 0.5Kg / l, an average particle size of 6±1μm, and a ...

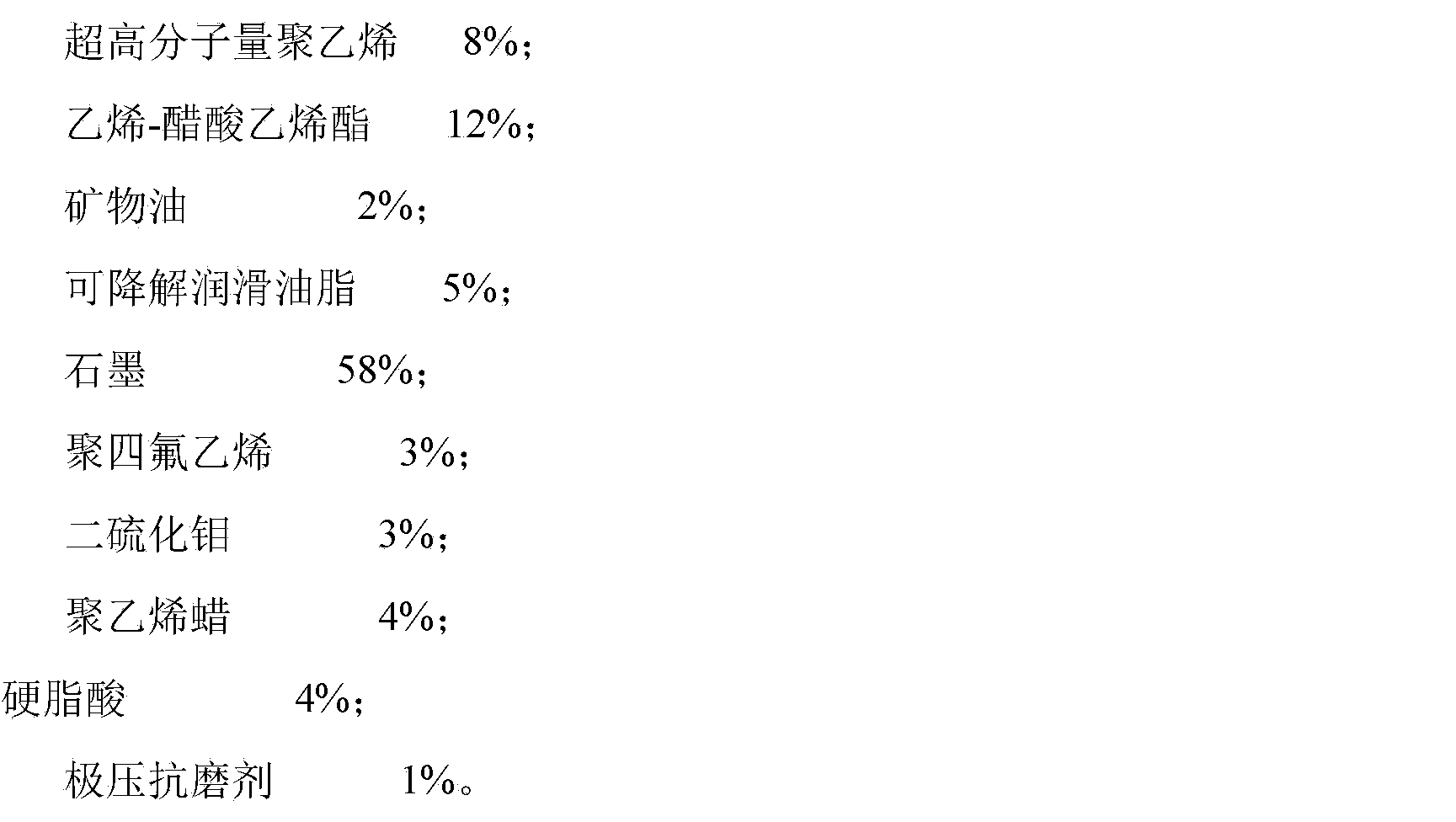

Embodiment 3

[0049] A composite solid lubricating stick shell of this embodiment is prepared from the following raw materials in weight percentage: ultra-high molecular weight polyethylene 6%; ethylene-vinyl acetate 28%; mineral oil 2%; degradable lubricating grease 5% ; Graphite 49%; PTFE 1%; molybdenum disulfide 2%; polyethylene wax 3%; stearic acid 3%, extreme pressure antiwear agent 1%. Molybdenum disulfide as a solid lubricant can reduce the friction coefficient. The ultra-high molecular weight polyethylene is white fine powder particles, and its average molecular weight is 1.5-2.5 million. The ethylene-vinyl acetate is a transparent particle, and the melt flow rate is 0.5 g / 10min-3 g / 10min. Described mineral oil is 500SN paraffin oil. The degradable lubricating grease is a degradable lubricating grease prepared from epoxy-esterification modified soybean oil. The polytetrafluoroethylene is superfine powder with a bulk density of 0.5Kg / l, an average particle size of 6±1μm, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com