Manufacturing method of waterproof and fireproof paper

A manufacturing method and technology of fireproof paper, applied in special paper, paper, papermaking and other directions, can solve the problems of paper inefficiency, waterproof paper, single function of fireproof paper, toxicity, etc., and achieve good softness and tear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take the production of 100 parts as an example to specifically illustrate the papermaking method of the present invention.

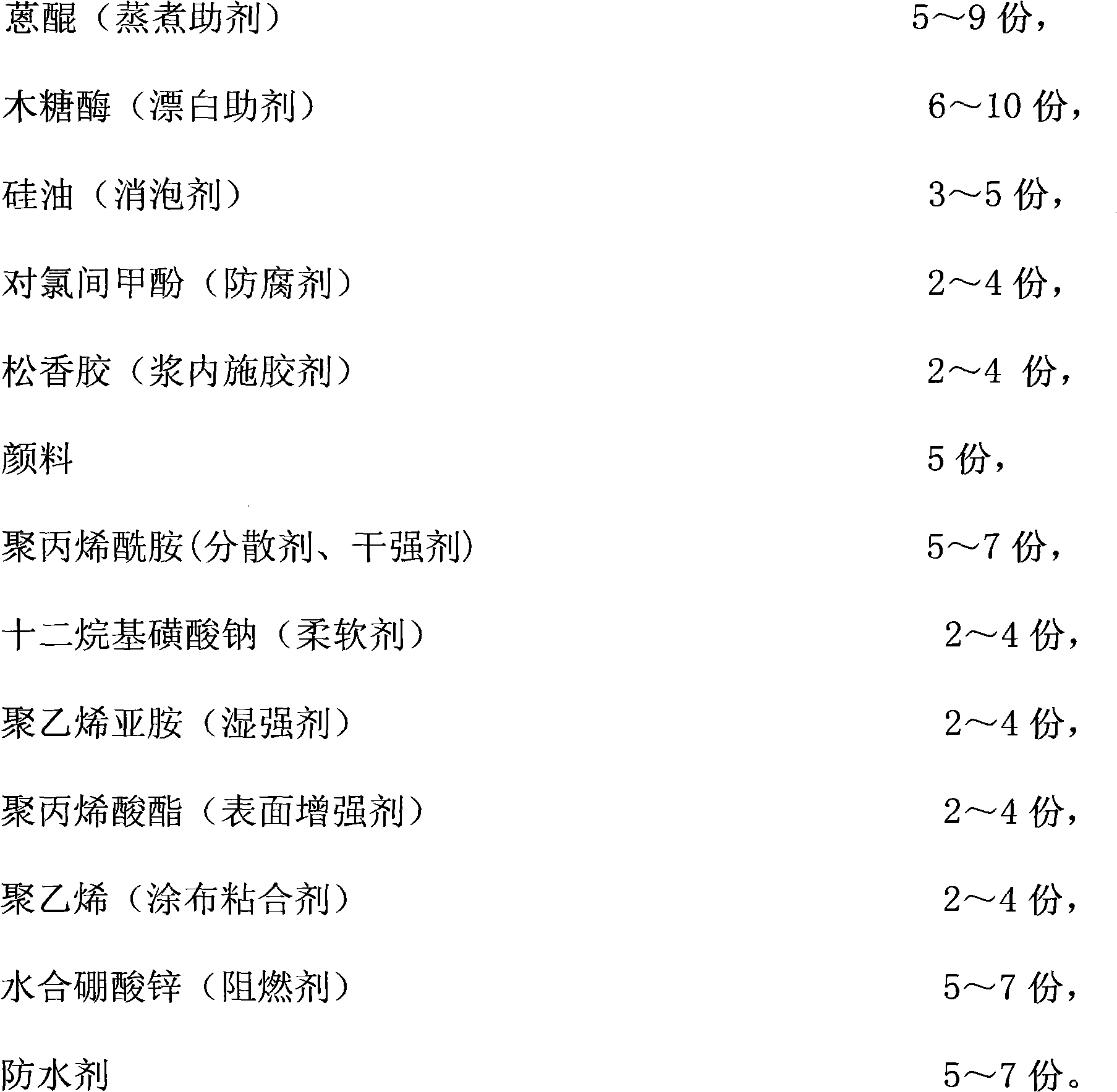

[0022] Weigh the material according to the following mass:

[0023] Fiber raw material: 50 parts, anthraquinone: 5 parts, xylosidase: 6 parts, silicone oil: 3 parts, p-chloro-m-cresol: 2 parts, rosin gum: 2 parts, pigment: 5 parts, polyacrylamide: 5 parts , Sodium dodecyl sulfonate: 2 parts, polyethyleneimine: 2 parts, polyacrylate: 2 parts, polyethylene: 2 parts, hydrated zinc borate: 5 parts, waterproofing agent: 5 parts.

[0024] Wherein, the waterproofing agent is taken as an example to produce 100 parts by mass to illustrate the papermaking method of the present invention.

[0025] Weigh the material according to the following mass:

[0026] It is prepared by mixing alkyl ketene dimer and polyamide epoxy resin in a weight ratio of 5:1.

[0027] Then proceed to the papermaking process:

[0028] (1) Pulping process:

[0029] a. Cooking: Th...

Embodiment 2

[0039] Take the production of 100 parts as an example to specifically illustrate the papermaking method of the present invention.

[0040] Weigh the material according to the following mass:

[0041] Fiber raw material: 55 parts, anthraquinone: 7 parts, xylase: 8 parts, silicone oil: 4 parts, p-chloro-m-cresol: 3 parts, rosin gum: 3 parts, pigment: 5 parts, polyacrylamide: 6 parts , Sodium dodecyl sulfonate: 3 parts, polyethyleneimine: 3 parts, polyacrylate: 3 parts, polyethylene: 3 parts, hydrated zinc borate: 6 parts, waterproofing agent: 6 parts.

[0042] Wherein, the waterproofing agent is prepared by mixing alkyl ketene dimer and polyamide epoxy resin in a weight ratio of 5:1.

[0043] Production technology is with embodiment 1.

Embodiment 3

[0045] Take the production of 100 parts as an example to specifically illustrate the papermaking method of the present invention.

[0046] Weigh the material according to the following mass:

[0047] Fiber raw material: 65 parts, anthraquinone: 9 parts, xylosidase: 10 parts, silicone oil: 5 parts, p-chloro-m-cresol: 4 parts, rosin gum: 4 parts, pigment: 5 parts, polyacrylamide: 7 parts , Sodium dodecyl sulfonate: 4 parts, polyethyleneimine: 4 parts, polyacrylate: 4 parts, polyethylene: 4 parts, hydrated zinc borate: 7 parts, waterproofing agent: 7 parts.

[0048] The waterproofing agent is prepared by mixing alkyl ketene dimer and polyamide epoxy resin in a weight ratio of 5:1.

[0049] Production technology is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com