Artificial texture stone and production method thereof

An artificial and textured technology, applied in the field of artificial stone, can solve problems such as poor decorative effect, and achieve the effect of good decorative effect, low cost and realistic texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

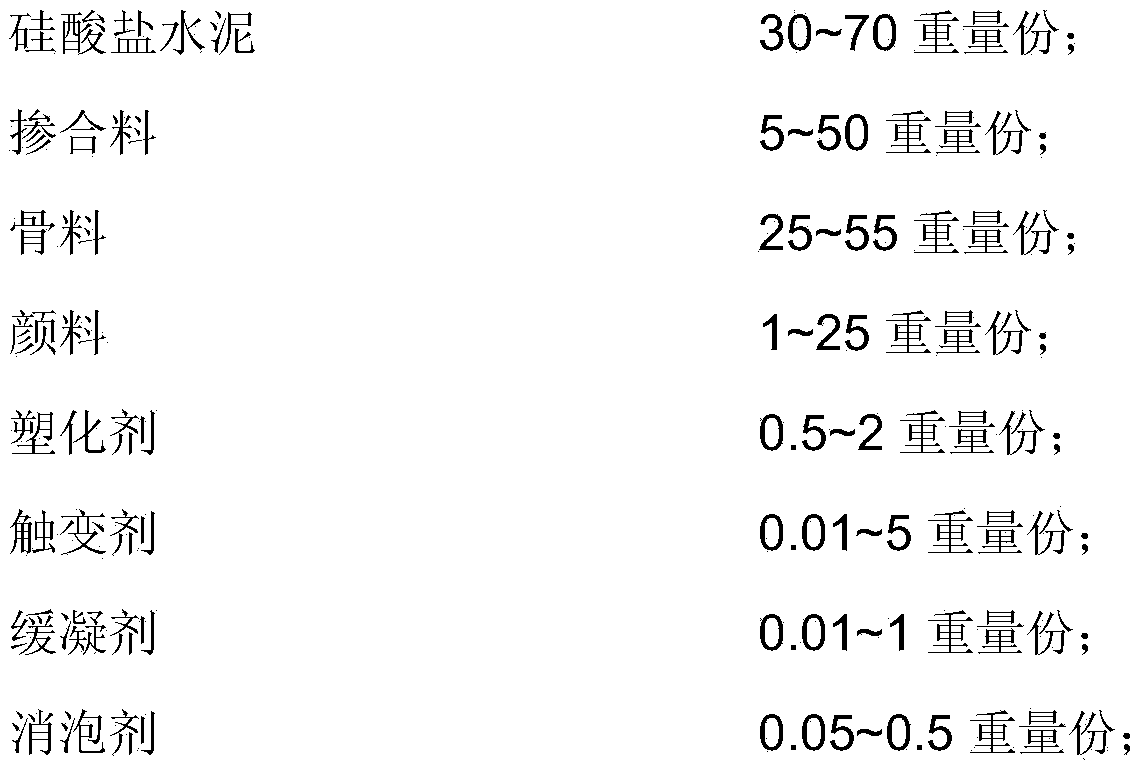

[0063] Step 1. Use natural or pre-processed stone models to remake molds according to market and customer needs. Prepare the main color paste and auxiliary color paste, the main color paste components include:

[0064] Portland cement 40kg;

[0065] Slag 5 kg;

[0066] 51 kg of 50~100 mesh quartz sand;

[0067] Pigment 3 kg;

[0068] High-performance polycarboxylate superplasticizer 0.5 kg;

[0069] Organic bentonite 0.5 kg;

[0070] Citric acid 0.1 kg;

[0071] Defoamer 0.2 kg;

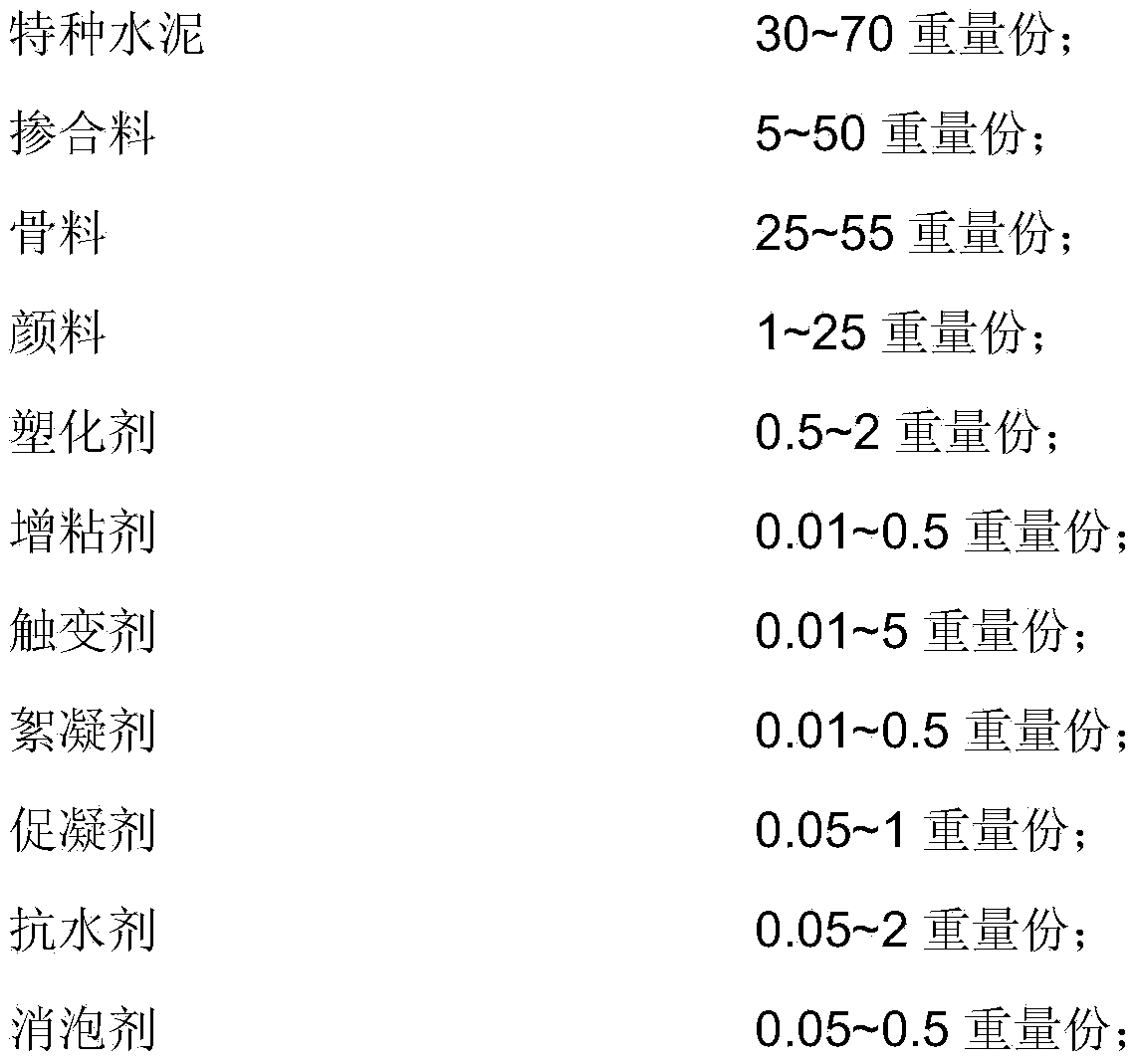

[0072] Correspondingly, the weight ratio of each component of the auxiliary color slurry is:

[0073] High alumina cement 50 kg;

[0074] Silica fume 5kg;

[0075] Colored sand 37kg;

[0076] Pigment 5kg;

[0077] High-performance polycarboxylate superplasticizer 0.5kg;

[0079] Organic bentonite 0.5kg;

[0080] Polyacrylamide 0.1kg;

[0081] Homemade coagulant 1kg;

[0082] Composite water repellent 1kg;

[0083] Defoamer 0.2kg;

[0084] Pre-mix the ...

Embodiment 2

[0089] Process 1. Use natural or pre-processed stone models to remake molds according to market and customer needs. Prepare main color paste and auxiliary color paste, wherein the main color paste components include:

[0090] White Portland cement 50kg;

[0091] Slag 8kg;

[0092] Rock chip 5kg;

[0093] Beige colored sand 15kg;

[0094] Color sand blue ash 18kg;

[0095] Pigment iron oxide yellow 3kg;

[0096] High-performance polycarboxylate superplasticizer 0.5kg;

[0098] Tartaric acid 0.02kg;

[0099] Defoamer 0.1kg;

[0100] Auxiliary color paste components include:

[0101] White high alumina cement 45kg;

[0102] Silica fume 14kg;

[0103] Rock chip 5kg;

[0104] Beige colored sand 15kg;

[0105] Color sand blue ash 18kg;

[0106] Pigment orange 5kg;

[0107] High-performance polycarboxylate superplasticizer 0.5kg;

[0108] Xanthan gum 0.4kg;

[0109] Attapulgite clay 5kg;

[0110] Polyethylene oxide 0.2kg;

[0111] Home...

Embodiment 3

[0119] Use natural or pre-processed stone models to reproduce molds according to market and customer needs. Prepare main color paste and auxiliary color paste, wherein the main color paste components include:

[0120] White Portland cement 50kg;

[0121] Fly ash 10kg;

[0122] Colored sand violet 5kg;

[0123] Beige colored sand 15kg;

[0124] Red top red colored sand 15kg;

[0125] Pigment iron oxide yellow 3kg;

[0126] High-performance polycarboxylate superplasticizer 0.5kg;

[0128] Tartaric acid 0.02kg;

[0129] Defoamer 0.1kg;

[0130] Auxiliary color paste components include:

[0131] Sulphoaluminate cement 50kg;

[0132] Slag 13kg;

[0133] Colored sand violet 4kg;

[0134] Beige colored sand 15kg;

[0135] Red top red colored sand 15kg;

[0136] Pigment brown red 5kg;

[0137] High-performance polycarboxylate superplasticizer 0.5kg;

[0138] Xanthan gum 0.4kg;

[0139] Attapulgite clay 5kg;

[0140] Polyethylene oxide 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com