Method for preparing rhombohedron single-crystal bismuth ferrite powder by fused salt

A technology of hexahedron and molten salt method, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., and can solve problems such as narrow temperature range, long synthesis cycle, and many process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 3.0670g Fe according to the Fe: Bi molar ratio of 1:1 2 o 3 and 8.9329g Bi 2 o 3 , Weigh 4.6261g of molten salt KCl and 7.3772g of KBr according to the mass ratio of molten salt to raw material 1:1, wherein the molar ratio of KCl:KBr is 1:1; the mixed Fe 2 o 3 、 Bi 2 o 3 Wet ball milling with molten salt for 2 hours, drying after ball milling, and then calcining at 750°C for 2 hours, cooling to room temperature with the furnace, and then fully washing with deionized water to remove KCl and KBr to obtain BiFeO 3 Powder.

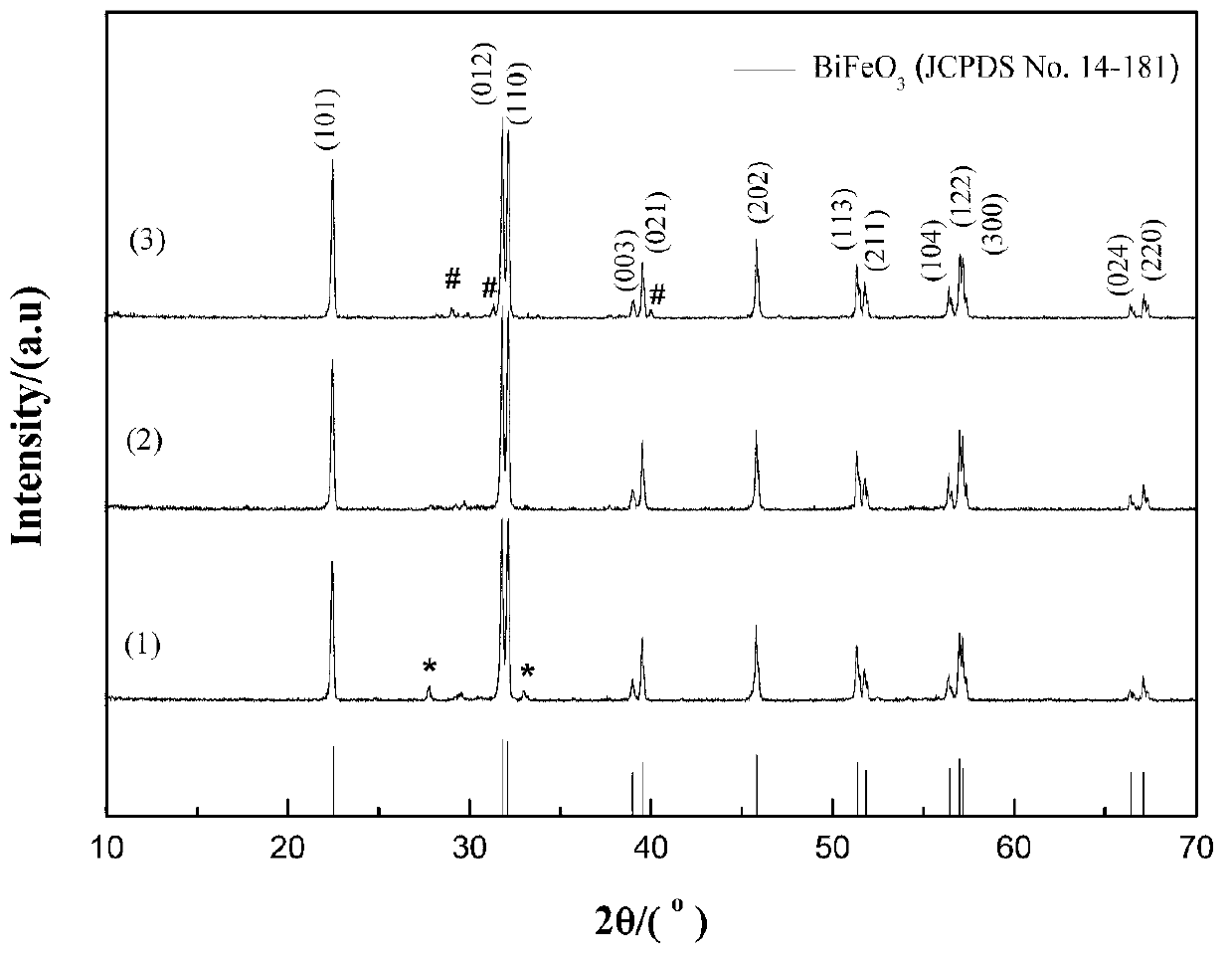

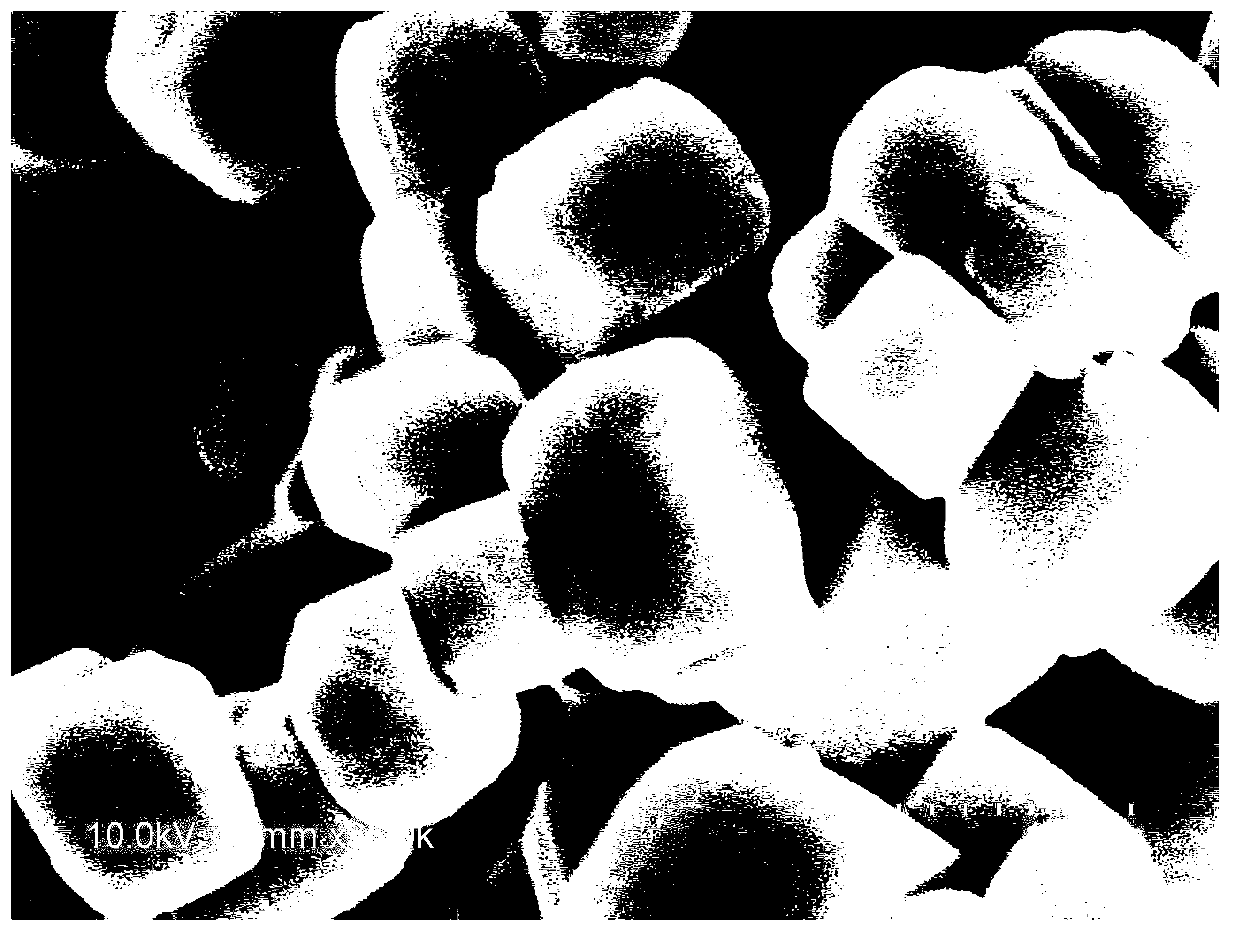

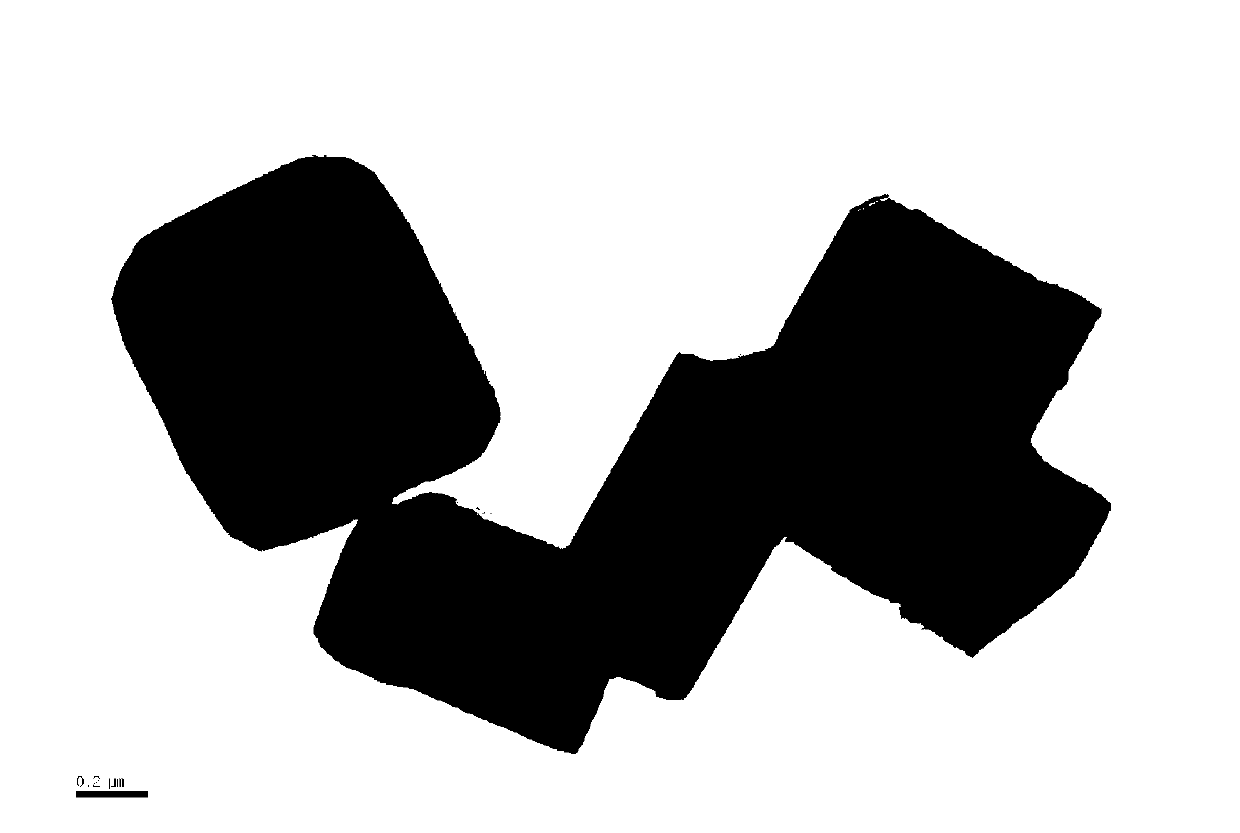

[0024] figure 1 , figure 2 , image 3 Using KCl and KBr compound salts as molten salts, keep BiFeO at different temperatures for 2 hours 3 X-ray diffraction pattern and grain morphology of the powder. X-ray diffraction and electron diffraction patterns show that single-phase, rhombohedral BiFeO was prepared by molten salt method 3 Powder.

Embodiment 2

[0026] Weigh 3.0640g Fe according to the Fe: Bi molar ratio of 1:1 2 o 3 and 8.9341g Bi 2 o 3 , Weigh 11.984g of molten salt KCl according to the mass ratio of molten salt to raw material 1:1; 2 o 3 、 Bi 2 o 3 Wet ball milling with KCl for 2 hours, drying after ball milling, and then calcining at 750°C for 2 hours, cooling to room temperature with the furnace, and then fully washing with deionized water to remove KCl to obtain BiFeO 3 Powder.

Embodiment 3

[0028] Weigh 3.0670g Fe according to Fe: Bi molar ratio of 1:1 2 o 3 and 8.9329gBi 2 o 3 , Weigh 12.0024g of molten salt KBr according to the mass ratio of molten salt to raw material 1:1; 2 o 3 、 Bi 2 o 3 Wet ball milling with molten salt for 2 hours, drying after ball milling, calcining at 750°C for 2 hours, cooling to room temperature with the furnace, and then fully washing with deionized water to remove KBr to obtain BiFeO 3 Powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com