Foaming agent for tailing sintering perforated brick and application thereof

The technology of porous brick and foaming agent is applied in the field of foaming agent for sintered porous bricks of tailings, which can solve the problems of increasing the production cost of sintered foam bricks, unable to control the shape and size of products, and increasing production costs, so as to achieve the utilization of tailings. Large, good thermal insulation effect, reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this example, tungsten mine tailings in Shizhuyuan Chuankou, Hunan Province are used as main raw materials, sucrose, starch and dry yeast are used as foaming agents, and citric acid is used as foaming accelerator to prepare sintered porous bricks. The chemical composition of the tungsten ore tailings used is weight content: SiO 2 79.28%, Al 2 o 3 10.17%, MgO 0.89%, CaO 2.47%, Fe 2 o 3 4.12%, Na 2 O 0.49%, K 2 O 2.08%, P 2 o 5 0.11%, TiO 2 0.30%, MnO 2 0.06%. The particle size of the tungsten tailings material is less than 1 mm. Material preparation is carried out according to the technological steps of following experiment:

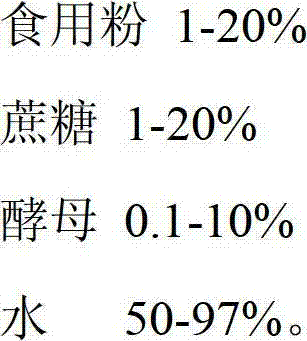

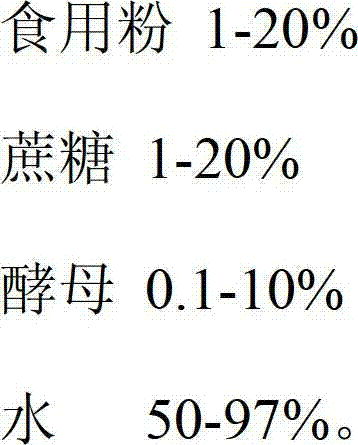

[0040] ① Weigh 2 grams of sucrose, 0.2 grams of starch and 0.02 grams of dry yeast respectively, dissolve them in 18.78 grams of water, stir to form a uniform suspension, and obtain a foaming agent for tailings sintered porous bricks;

[0041] ② Dissolve 2 grams of citric acid foaming accelerator in 20 grams of water, then slowly dro...

Embodiment 2

[0049] In this example, the tailings of tungsten ore in Chuankou, Shizhuyuan, Hunan Province are used as the main raw material, and the chemical composition of the tungsten ore tailings used is the weight content: SiO 2 79.28%, Al 2 o 3 10.17%, MgO 0.89%, CaO 2.47%, Fe 2 o 3 4.12%, Na 2 O 0.49%, K 2 O 2.08%, P 2 o 5 0.11%, TiO 2 0.30%, MnO 2 0.06%. The particle size of the tungsten tailings material is less than 1 mm. Sintered porous bricks were prepared with sucrose, starch and dry yeast as foaming agents and citric acid as foaming accelerator. Material preparation is carried out according to the technological steps of following experiment:

[0050] ① Weigh 2.5 grams of sucrose, 2.5 grams of starch, 0.5 grams of dry yeast and 0.5 grams of polyvinyl alcohol, and dissolve them in 44 grams of water, stir to form a uniform suspension, and obtain the foaming material for tailings sintered porous bricks. agent;

[0051] ② Dissolve 4 grams of citric acid foaming acceler...

Embodiment 3

[0059] In this example, tungsten mine tailings in Shizhuyuan Chuankou, Hunan Province are used as main raw materials, sucrose, starch and dry yeast are used as foaming agents, and citric acid is used as foaming accelerator to prepare sintered porous bricks. The chemical composition of the tungsten ore tailings used is weight content: SiO 2 79.28%, Al 2 o 3 10.17%, MgO 0.89%, CaO 2.47%, Fe 2 o 3 4.12%, Na 2 O 0.49%, K 2 O 2.08%, P 2 o 5 0.11%, TiO 2 0.30%, MnO 2 0.06%. The particle size of the tungsten tailings material is less than 1 mm. Material preparation is carried out according to the technological steps of following experiment:

[0060] ① Weigh 20 grams of sucrose, 1.5 grams of starch and 10 grams of dry yeast respectively, and dissolve them in 68.5 grams of water, stir to form a uniform suspension, and obtain a foaming agent for tailings sintered porous bricks;

[0061] ② Dissolve 4.5 grams of citric acid foaming accelerator in 20 grams of water, then slowly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Volume specific gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com