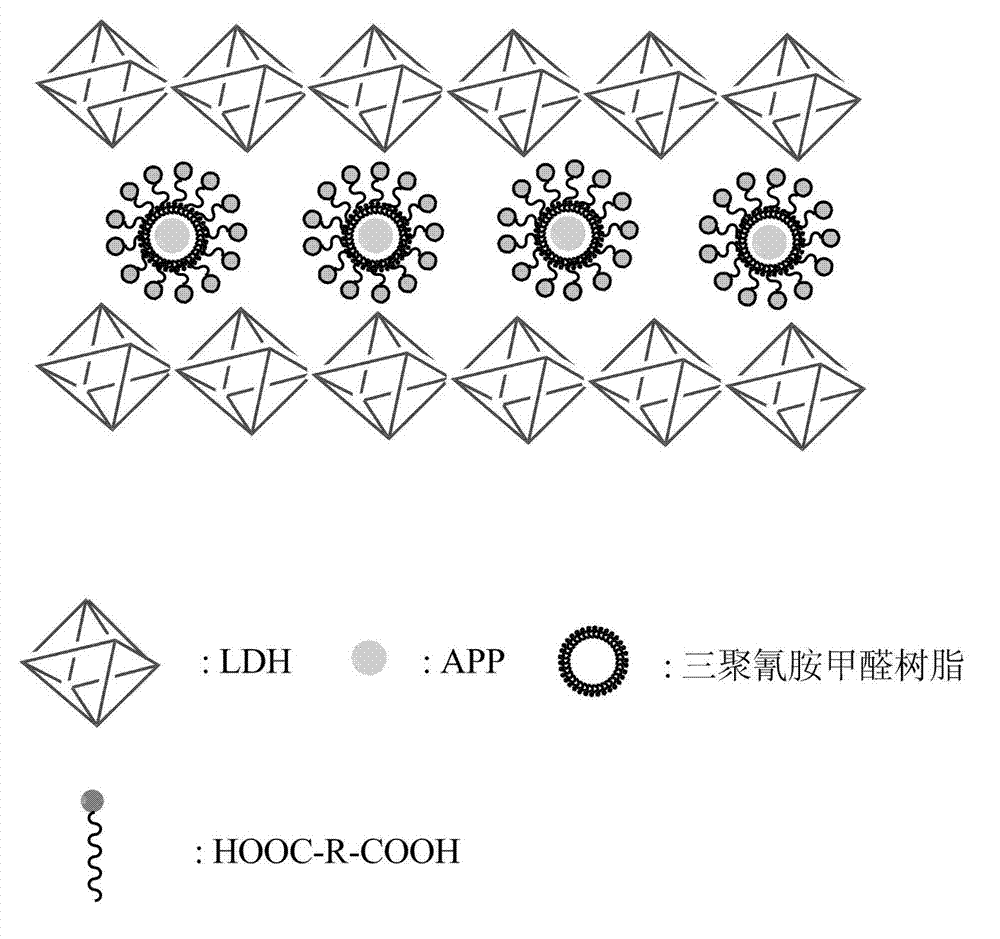

Core-shell-structure phosphorus-nitrogen compound modified hydrotalcite-like flame retardant and preparation method thereof

A technology of shell structure and compound, which is applied in the field of core-shell structure phosphorus nitrogen compound modified hydrotalcite-like flame retardant and its preparation, can solve the problems of poor compatibility between inorganic hydrotalcite-like and polymer materials, and reduce heat Effect of release rate, increased interlayer spacing, and good action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 7.5g of melamine and 4mL of 37% formaldehyde (molar ratio is 3:1) in 20mL of deionized water, add 10% sodium carbonate solution drop by drop under stirring conditions to adjust pH=8, heat to 80 ° C constant temperature reaction 1h.

[0032] (2) Dissolve 40g of ammonium polyphosphate into 150mL of ethanol, then add the solution described in (1), adjust the pH between 4 and 5 with 1mol / L sulfuric acid, heat to 80°C for 2 hours at a constant temperature, after the reaction, filter with suction , washed and dried at 60°C.

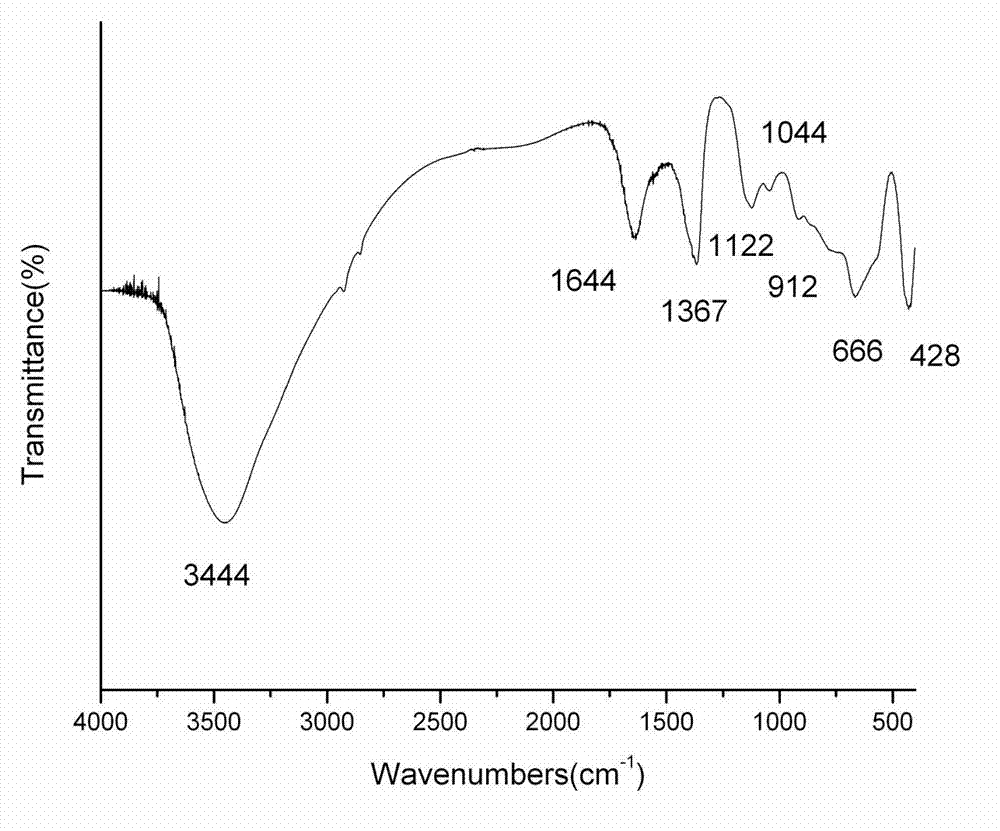

[0033] (3) Dissolve 0.5g of the substance obtained in (2) and 0.5g of 4,4'-dicarboxydiphenyl ether in 100mL of dichloromethane, stir at room temperature for 24 hours, centrifuge, filter with suction, wash, and dry at 60°C to obtain the nucleus -Phosphorus nitrogen compounds with a shell structure. Its TGA-DTG curve is as follows Figure 4 shown.

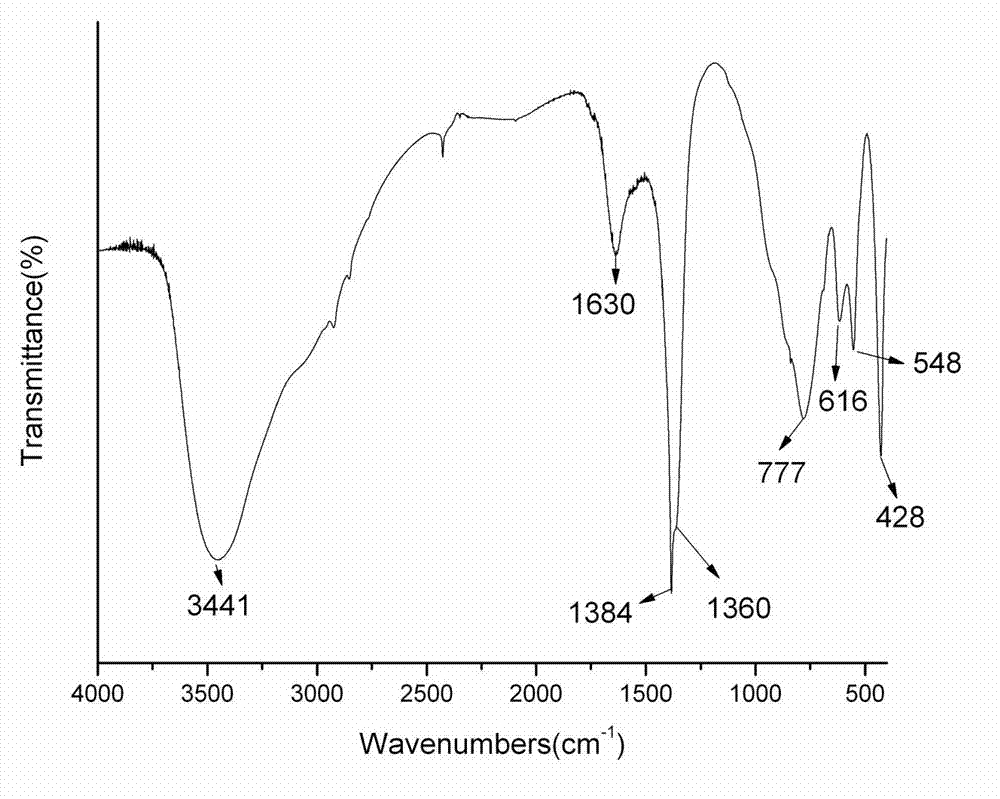

[0034] ⑷The 3.60g MgCl 2 ·6H 2 O and 2.25g AlCl 3 ·6H 2 O was dissolved in 100 mL deion...

Embodiment 2

[0038] The method steps of preparing the core-shell structure phosphorus nitrogen compound modified hydrotalcite-like flame retardant are the same as those described in Example 1, the ammonium polyphosphate and 4,4'-dicarboxyl Take 0.5g and 0.4g of diphenyl ether respectively.

Embodiment 3

[0040] The method steps for preparing a core-shell structure phosphorus nitrogen compound modified hydrotalcite-like flame retardant are the same as those described in Example 1, except that 4,4'-dicarboxydiphenyl ether in (3) is replaced by malonic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com