Lithium-ion battery positive material coated with metal phosphate on surface and preparation method of lithium-ion battery positive material

A surface-coated phosphoric acid and lithium-ion battery technology, applied to battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problems of large particles, long time, high process requirements, etc., to achieve cycle stability and Improved magnification performance, easy industrial production, and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 100 g of polyacrylamide aqueous solution with a weight percentage of 0.5% (that is, 0.5 wt %), and add 50 g of positive electrode material Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 , magnetic stirring for 3h; add 0.05mol / L of (NH 4 ) 2 HPO 4 Solution 147ml and 0.05mol / L Zr(NO 3 ) 4 The solution was 92ml, stirred continuously for 24h, then filtered, dried, and finally heat-treated at 400°C for 2h to obtain a positive electrode material with a surface coating amount of 2wt%.

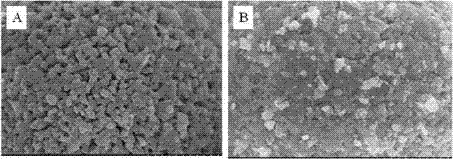

[0028] Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 Surface coated with Zr 3 (PO 4 ) 4 Scanning electron microscope (SEM) images of before and after figure 1 As shown, it can be seen that there are obvious nano-scale coating particles on the surface of the modified material.

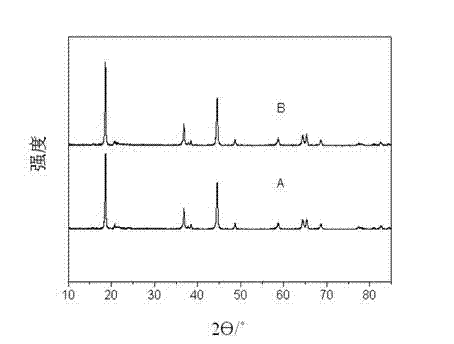

[0029] Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 Surface coated with Zr 3 (PO 4 ) 4 X-ray diffraction (XRD) images before and after figure 2 As shown, it can be seen that the crystal structure has not chan...

Embodiment 2

[0032] Weigh 0.5wt% polyacrylamide aqueous solution 100g, add 50g positive electrode material Li[Li] wherein 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 , magnetically stirred for 3h; then sequentially added 0.025mol / L (NH 4 ) 2 HPO 4Solution 197ml and 0.025mol / L Al(NO 3 ) 3 The solution was 164ml, stirred continuously for 24h, then filtered, dried, and finally heat-treated at 400°C for 2h to obtain a positive electrode material with a surface coating amount of 1wt%.

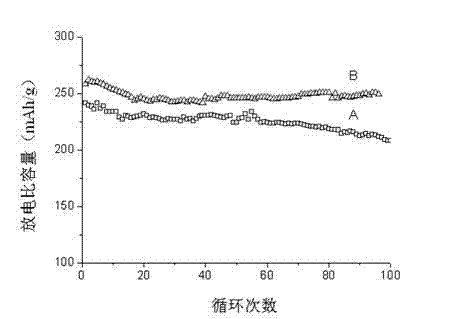

[0033] Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 Surface coated with AlPO 4 The cycle performance curve before and after Figure 4 As shown, it can be seen that the first discharge capacity of the material before coating is 241.1mAh / g, when charging and discharging at 0.1C, 2~4.8V, the capacity retention rate after 100 cycles is 86.4%; the coated AlPO 4 The first discharge capacity of the final positive electrode material is 261.3mAh / g, when charging and discharging at 0.1C, 2~4.8V, the capacity retention rate ...

Embodiment 3

[0036] Weigh 150g of 0.25wt% polyacrylamide aqueous solution, add 50g of positive electrode material Li[Li] wherein 0.13 mn 0.47 Ni 0.2 co 0.2 ]O 2 , magnetically stirred for 3h; then sequentially added 0.05mol / L (NH 4 ) 2 HPO 4 Solution 74ml and 0.05mol / L Zr(NO 3 ) 4 46ml of the solution was stirred continuously for 24 hours, then filtered, dried, and finally heat-treated at 300°C for 2 hours to obtain a positive electrode material with a surface coating amount of 1wt%.

[0037] Li[Li 0.13 mn 0.47 Ni 0.2 co 0.2 ]O 2 Surface coated with Zr 3 (PO 4 ) 4 The cycle performance curve before and after Image 6 As shown, it can be seen from the figure that the first discharge capacity of the material before coating is 231.1mAh / g, when charging and discharging at 0.1C, 2~4.8V, the capacity retention rate after 50 cycles is 87.1%; the coating Zr 3 (PO 4 ) 4 After Li[Li 0.13 mn 0.47 Ni 0.2 co 0.2 ]O 2 The initial discharge capacity of the material is 243.8mAh / g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com