Desulfurization denitration method

A technology of desulfurization and denitrification, desulfurization tower, applied in the field of synchronous desulfurization and denitrification, desulfurization and denitrification, can solve the problems of high single efficiency, large floor area, low joint efficiency, etc., and achieve the effect of improving efficiency, low operating cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] In the present invention, the preparation method of nano-agent desulfurization and denitrification agent comprises the following steps:

[0081] (1) Prepare the following components to make a mixture;

[0082] (2) Making the prepared mixture into a nanoscale desulfurization and denitrification agent.

[0083] Preferably, the components include MgO, SiO 2 , CaO, Fe 2 o 3 、Al 2 o 3 , CuO and MnO 2 ; Optionally, also include KMnO 4 .

[0084] According to the preparation method of the present invention, preferably, comprises the following steps:

[0085] (1) prepare the mixture of the above-mentioned components according to the above-mentioned ratio;

[0086] (2) Making the prepared mixture into a nanoscale desulfurization and denitrification agent.

[0087] In the present invention, preferably, step (2) includes the following steps:

[0088] ① pulverizing the mixture into nanoscale powder;

[0089] ② preparing the nano-scale powder into a paste-like substance; ...

Embodiment 1

[0131] (1) Modulation of desulfurization and denitrification agent:

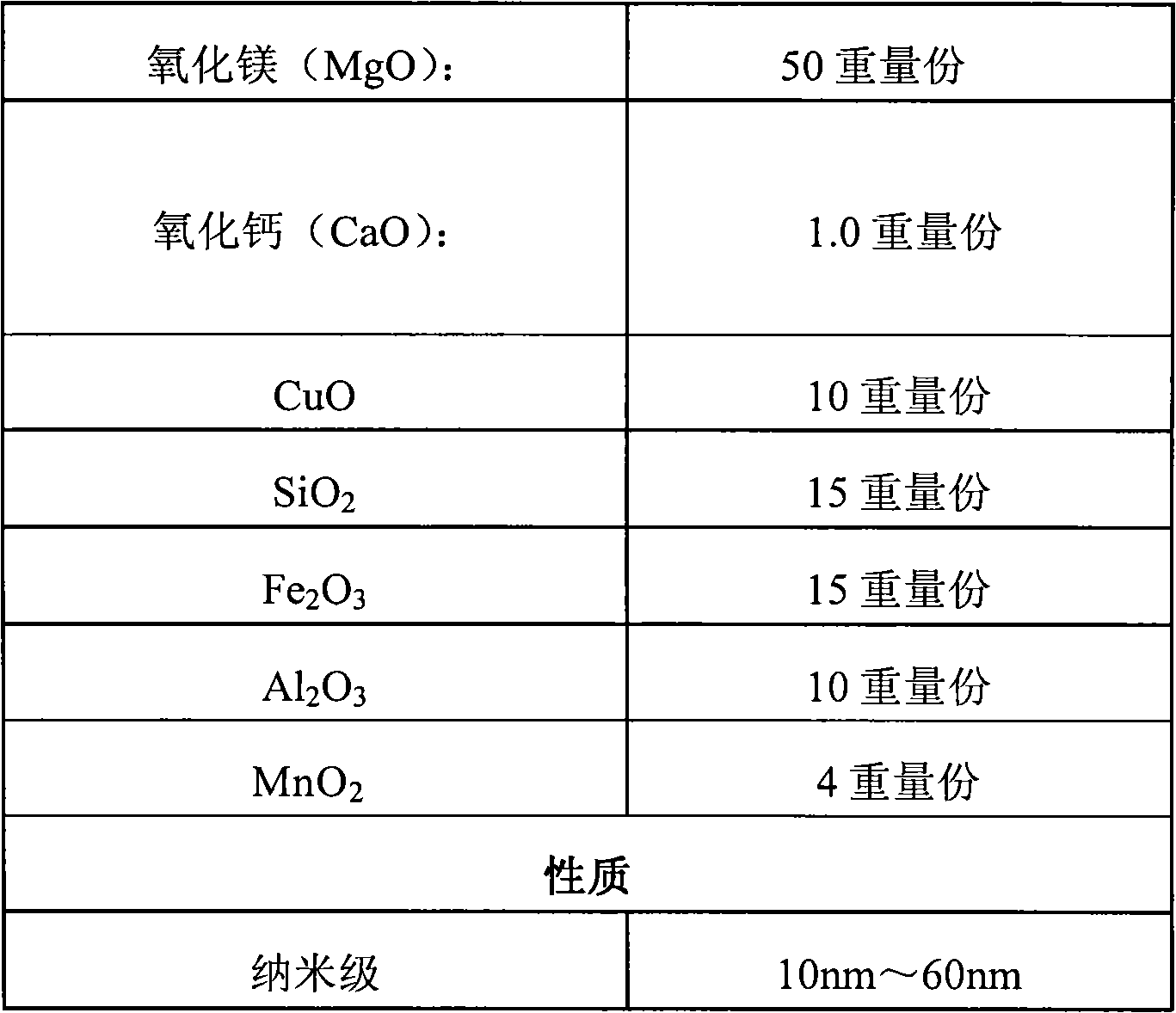

[0132] According to the following formula, mix the components evenly to obtain the desulfurization and denitrification agent.

[0133]

[0134] Put the metal-based oxide desulfurization and denitrification agent prepared according to the ratio in the above table into a high-energy ball mill and grind it into nanoscale specifications within the range of 10nm to 60nm, add water to the desulfurization and denitrification agent nano powder after machine grinding, stir evenly, and then add Enter the industrial thickener HPMC (hydroxypropyl methylcellulose), send the mixed slurry into a single-chamber furnace, and roast it at a temperature range of 600°C to 800°C for 1.5 to 2 hours to obtain a desulfurization and denitrification agent .

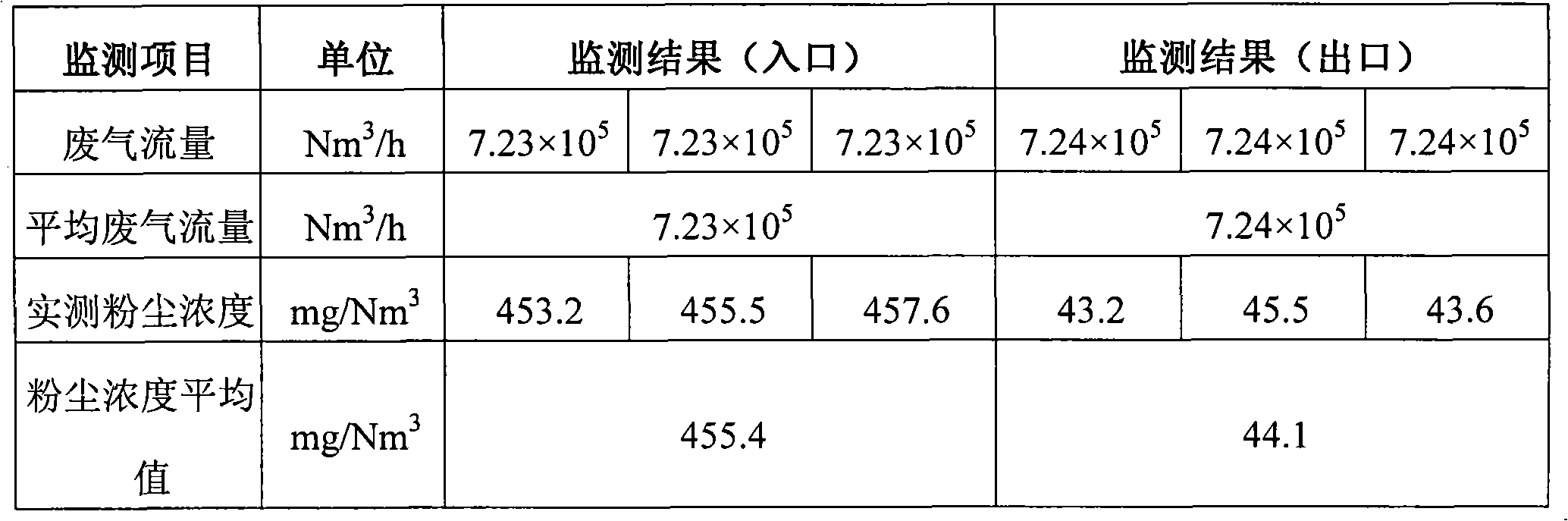

[0135] (2) Removal of SO using nanoscale desulfurization and denitrification agents 2 , NO X craft

[0136] 1. Pulping:

[0137] The prepared desulfurization and denitrif...

Embodiment 2

[0158] According to the following formula, mix the components evenly to obtain the desulfurization and denitrification agent.

[0159]

[0160]

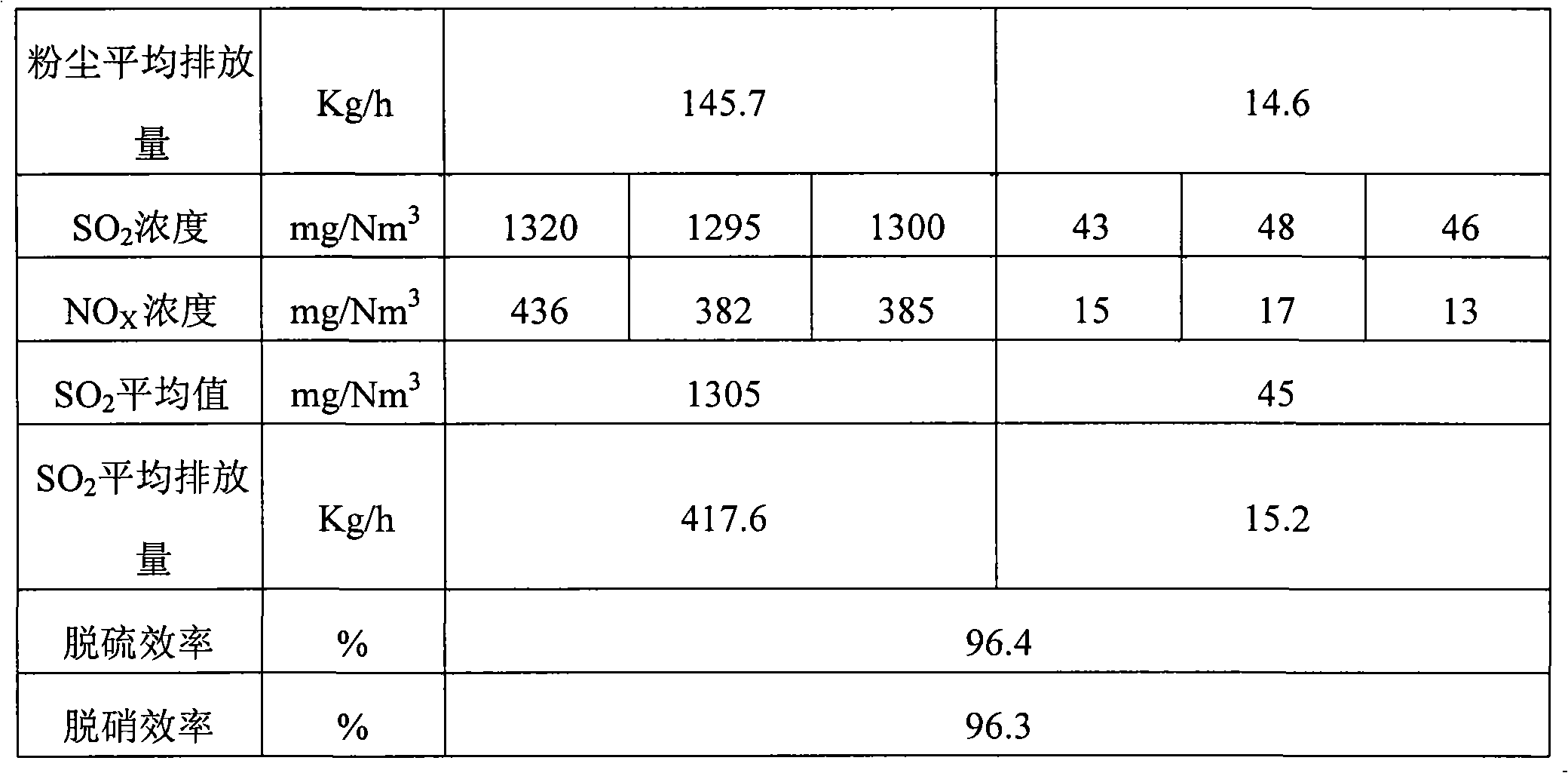

[0161] Compared with Example 1, Example 2 reduces MgO content by 5 parts by weight, reduces MnO 2 2 parts by weight, increase SiO 2 , Fe 2 o 3 5 parts by weight, increase KMnO 4 2 parts, other conditions are constant, and technological process is also identical with embodiment 1, obtains following parameter list:

[0162] Table 3: Monitoring results of waste gas emission from sintering machine desulfurization facilities

[0163]

[0164] The desulfurization efficiency reaches 96.9%, and the denitrification efficiency reaches 93.1%.

[0165] At the same time, the consumption parameters of various consumables are as follows:

[0166] Various experimental data

[0167] 1 power consumption Spend 158 2 Water Consumption t / h 20 3 Consumption of desulfurization and denitrification agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com