Process for producing sulfur and light calcium carbonate from phosphorus gypsum

A light calcium carbonate, phosphogypsum technology, applied in the preparation/purification of calcium carbonate/strontium/barium, sulfur, etc., can solve the problems of low thermal efficiency, low sulfur conversion rate, environmental pollution, etc., and achieves low production cost and construction. The effect of low cost and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

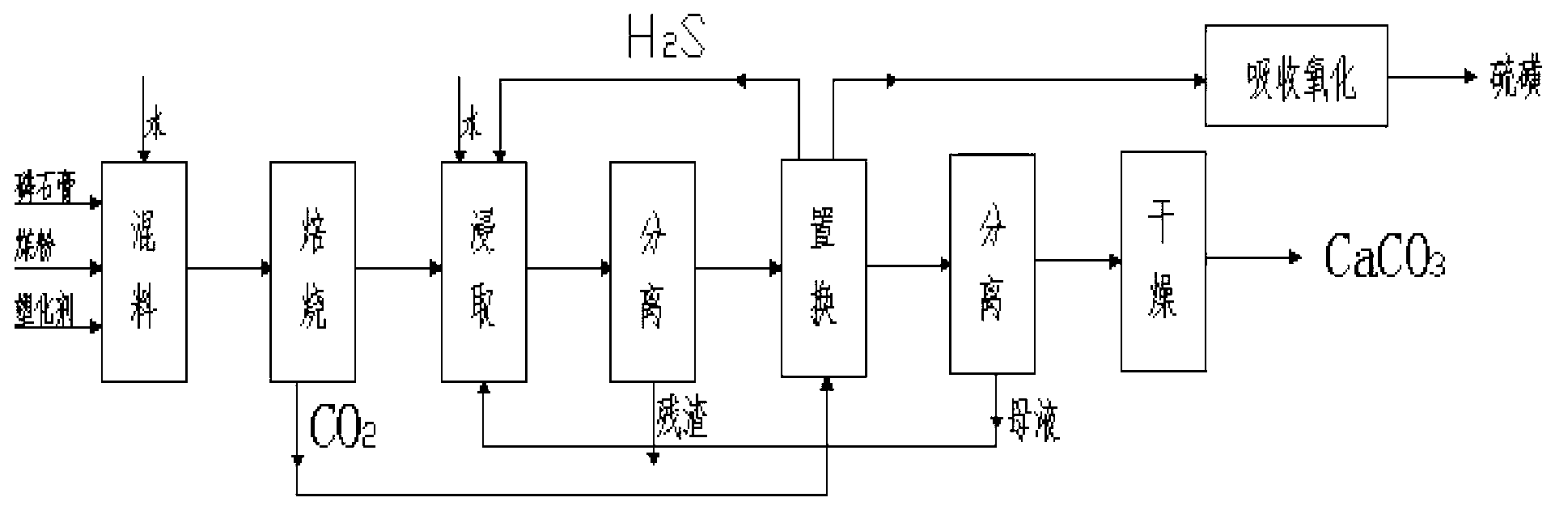

[0020] like figure 1 As shown, make a mixture of phosphogypsum and coal in a molar ratio of 1:2~3, add 1~5% of the weight of the mixture as a plasticizer and an appropriate amount of water, stir evenly, and use a press or extruder Molded into hollow blocks, stacked on the kiln car with a stacking machine or a manipulator; after being dried in a tunnel drying room and reduced and roasted in a tunnel kiln, the phosphogypsum is converted into calcium sulfide, and carbon dioxide is released; calcium sulfide powder is added to the water at the same time. Hydrogen sulfide gas Carry out leaching to generate calcium hydrosulfide soluble in water; carbon dioxide gas is introduced into the calcium hydrosulfide solution for replacement to generate light calcium carbonate precipitate and hydrogen sulfide gas; hydrogen sulfide gas is used to produce sulfur by wet absorption oxidation method. Wherein the roasting temperature is 900-1200 DEG C, the carbon monoxide content in the reducing atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com